Method for correcting blade modal testing result of horizontal axis wind turbine

A technology for wind turbine blade and modal testing, which is used in the testing of mechanical components, the testing of machine/structural components, and measuring devices, etc., which can solve the problem that the requirements for safe operation of blades and units cannot be met, and the natural frequency of blades cannot be accurately estimated. problems, to achieve the effect of reducing inspection costs, optimizing design, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

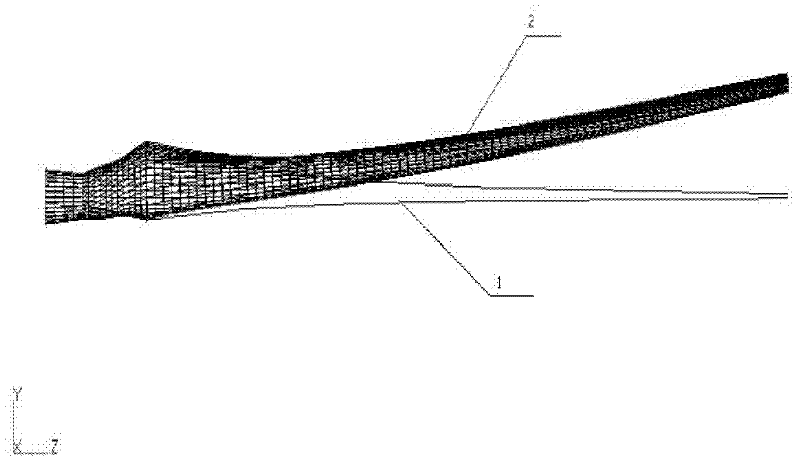

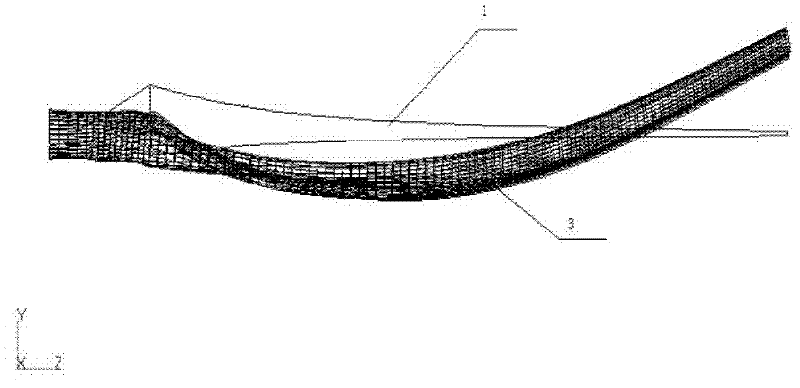

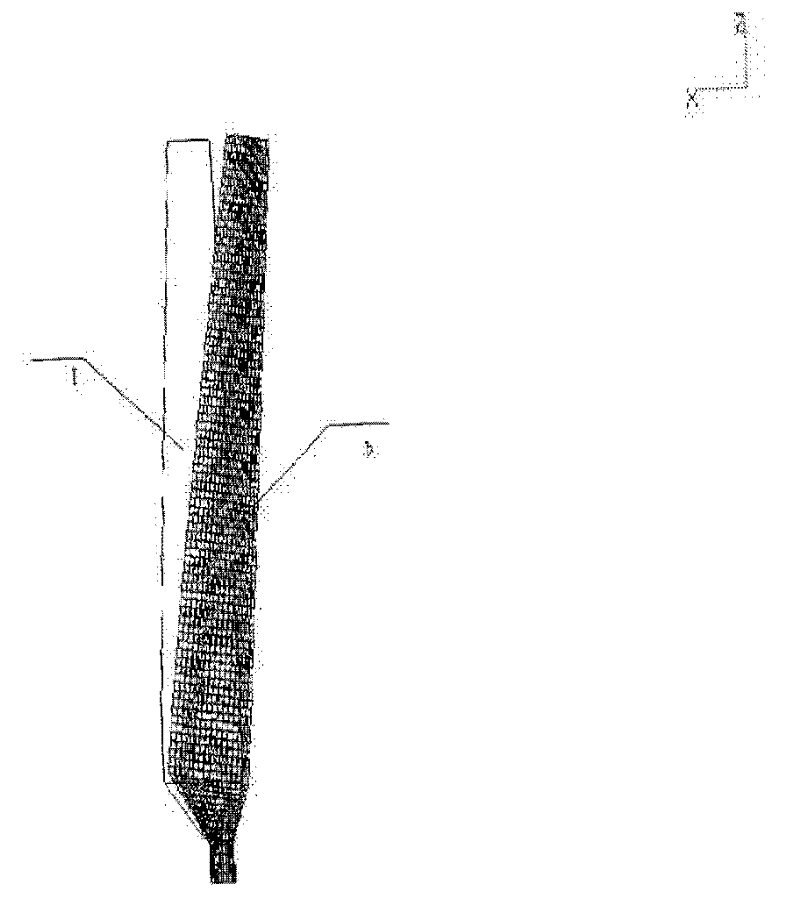

[0033] The object of this embodiment is a 1.5MW wind turbine, and the speed of the wind rotor is in the range of 11-19rpm under the operating condition of the turbine. Since the torsional stiffness of the blade is relatively high, and the torsional frequency is in the safe range, this example only analyzes the modes in the flapping and shimmy directions. The following steps are used to test the structural frequency of the blade and correct the results. For the convenience of description, the load in this example is The effect on frequency is only analyzed for the effect of inertial loads:

[0034] 1) Fix the blade on the test bench, determine the layout of the blade surface sensors according to the characteristics of different mode shapes of the blade, use the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com