Asphalt mixture test fixture and using method thereof

A technology of asphalt mixture and test fixture, which is applied in the direction of applying repeated force/pulsation force to test material strength, analyze materials, instruments, etc., and can solve the differences in test data, large volume, and the inability to use mixture freeze-thaw splitting tests, etc. problem, to achieve the effect of convenient use and small clamp volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

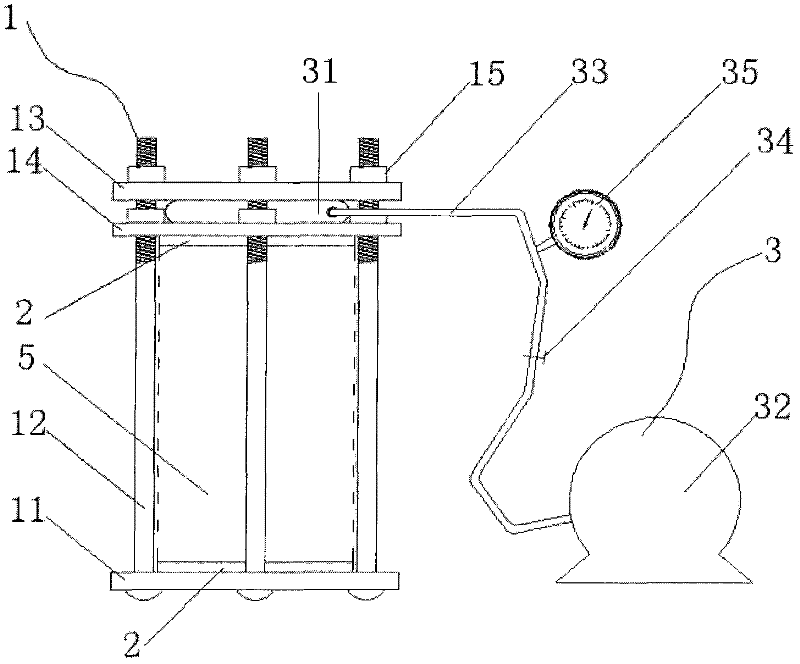

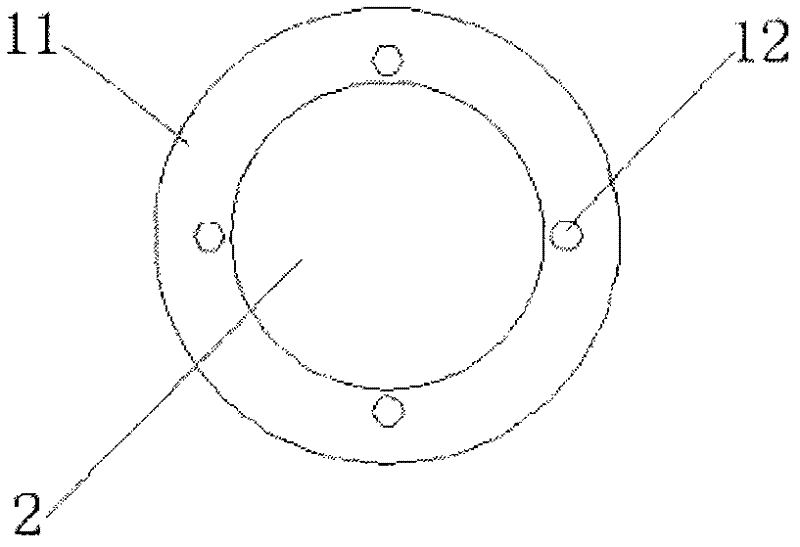

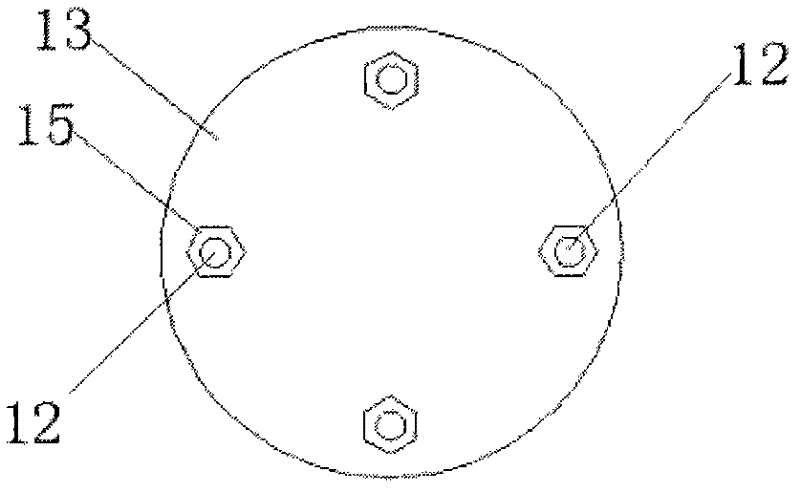

[0040] Such as Figure 1~3 Shown, the asphalt mixture test fixture of the present invention comprises frame (1), spacer (2), booster air bag (3); Composed of a circular pressure plate (14) and a circular top plate (13), the height and diameter of the inner cavity of the frame (1) are larger than the size of the test piece (5); 4 side bars (12) are parallel and symmetrical around the center of the bottom plate (11) Arrangement, the diameter of the inner cavity surrounded by four side rods (12) is larger than the diameter of the test piece (5), the lower end of the side rods (12) is vertically connected with the bottom plate (11), and the upper end is threaded for a certain length, and a limit nut is provided (15); the pressing plate (14) and the top plate (13) are located directly above the base plate (11) and are parallel to the base plate (11), and there are notches or perforations at the position of the corresponding side bar (12), and the pressing plate (14) and the top pla...

Embodiment 2

[0053] Such as Figure 1~4 Shown, a kind of asphalt mixture test fixture is made up of frame (1), spacer (2), solid force measuring device (4); Solid force measuring device (4) is made up of solid sensor (41), dynamometer ( 43), lead wire (42), solid sensor (41) and dynamometer (43) are connected with lead wire (42), and solid sensor (41) has parallel, upper and lower two planes, and diameter is smaller than test piece diameter, and solid sensor (41) The upper and lower planes are attached to the bottom surface of the top plate (13) and the top surface of the pressure plate (14); the solid sensor (41) is a pressure sensor, and its upper and lower planes are pressure bearing surfaces; the rest of the structure is the same as in Embodiment 1 same.

[0054] Steps for continuous force application using a fixture with a solid dynamometer:

[0055] Step 1: Take the connected bottom plate (11) and side bar (12), and place spacer (2), test piece (5), spacer (2), pressure plate (14) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com