Static-error-free high-precision instrument temperature control circuit

A temperature control, high-precision technology, used in temperature control, non-electric variable control, control/regulation systems, etc., can solve problems such as low reliability of instrument temperature control circuits, eliminate static errors, reduce interference, and achieve high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

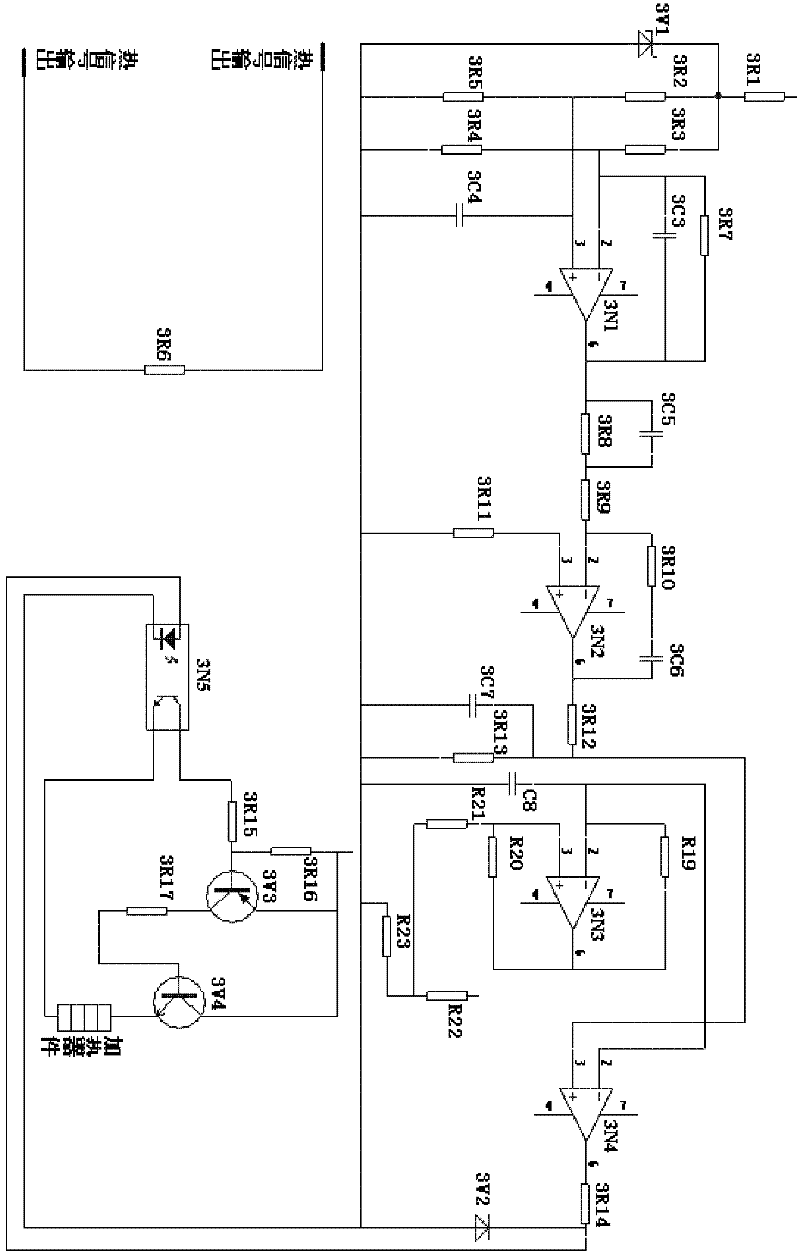

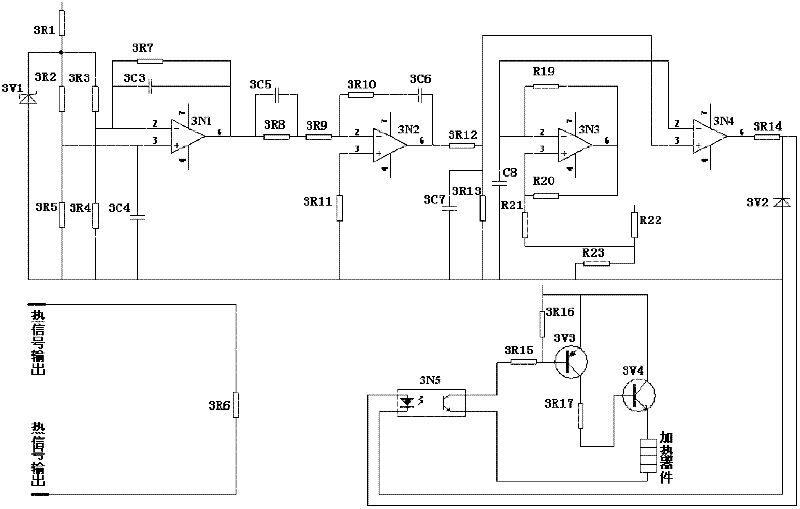

[0022] See figure 1 , the details are as follows:

[0023] 1. The first thermistor 3R5 converts the heat signal into a variable resistance value.

[0024] 2. The heat signal is converted into a voltage signal through the bridge composed of 3R1, 3R2, 3R3, 3R4, 3R5, 3R7, and 3N1.

[0025] 3. The voltage signal goes through 3C5, 3R8, 3R10, 3C6, 3R12, 3R13, and 3N2 for differential, integral, and proportional operations, that is, PID operations. 3C5 performs differential processing on the input signal, and 3C6 performs integral processing on the input signal; 3R12 and 3R13 are output voltage dividing resistors;

[0026] 4. The calculated signal is compared with the frequency signal from 3N3 self-excited oscillation through 3N4 to generate a pulse width modulation signal.

[0027] 5. The pulse width modulation signal is isolated by 3N5.

[0028] 6. The isolated pulse width modulation signal drives the heating device through 3V3 and 3V4.

[0029] 7. The heat generated by the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com