Semiconductor apparatus and method for manufacturing the semiconductor apparatus

A semiconductor and plasma technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of HEMTs that are difficult to obtain stable operating characteristics, and achieve the effect of reducing the etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] (semiconductor device)

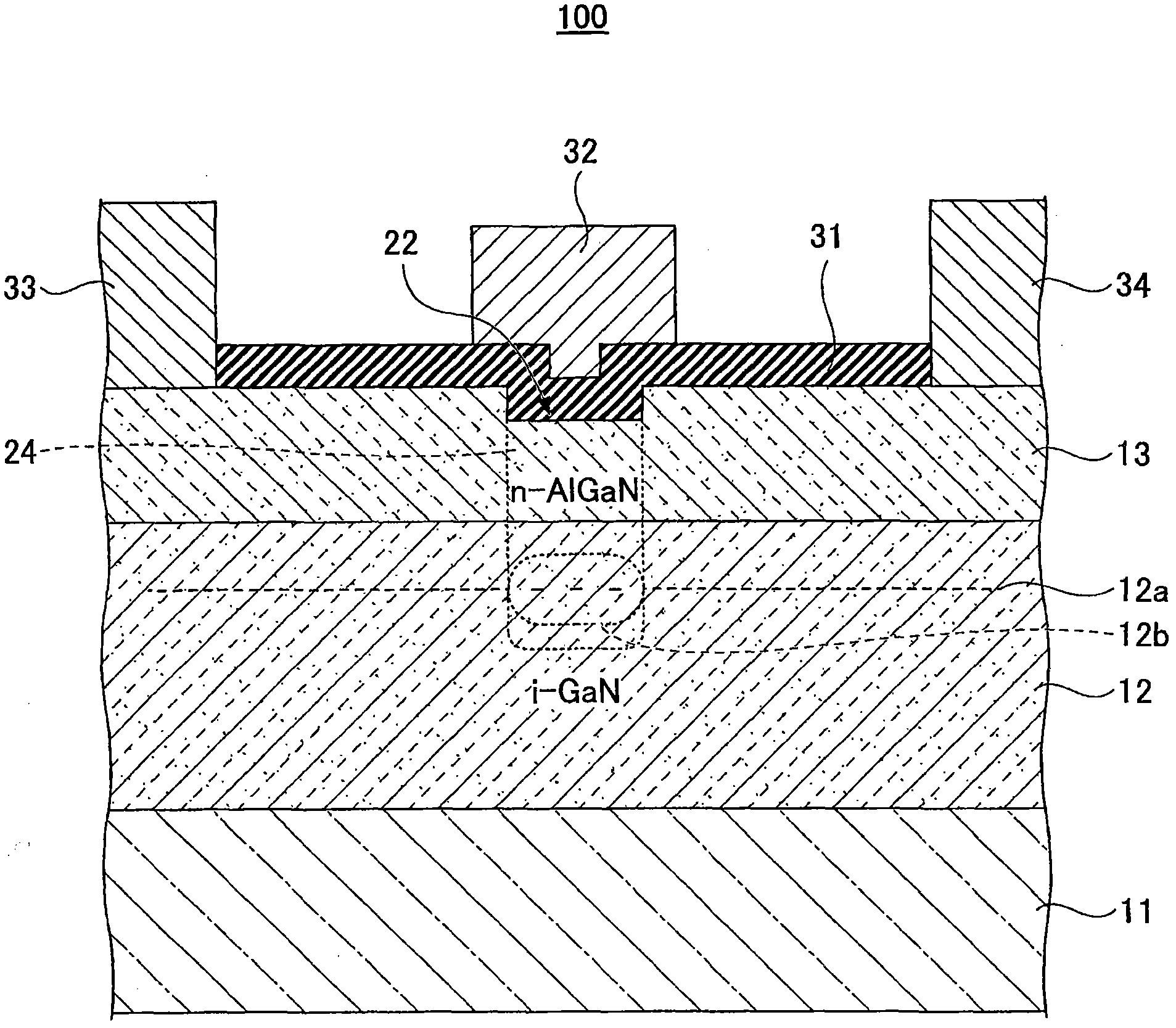

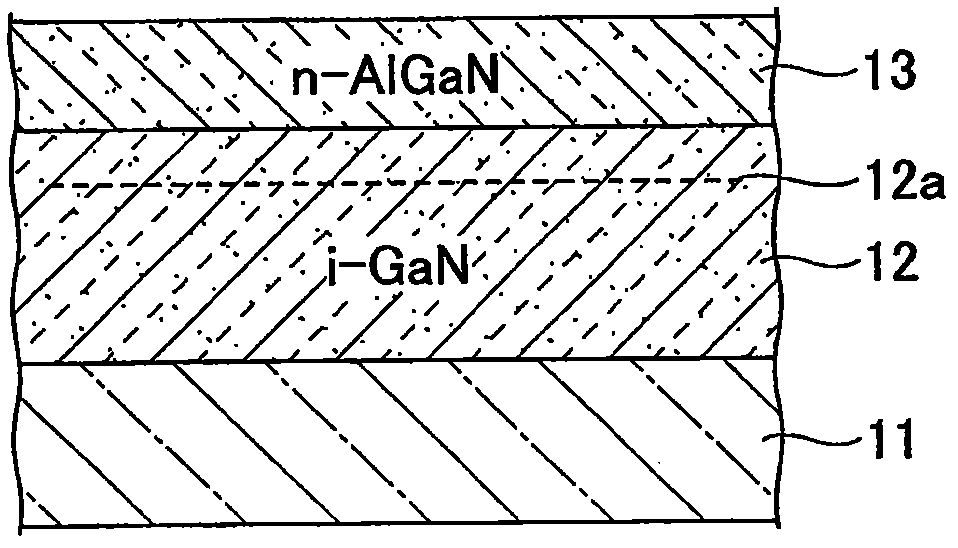

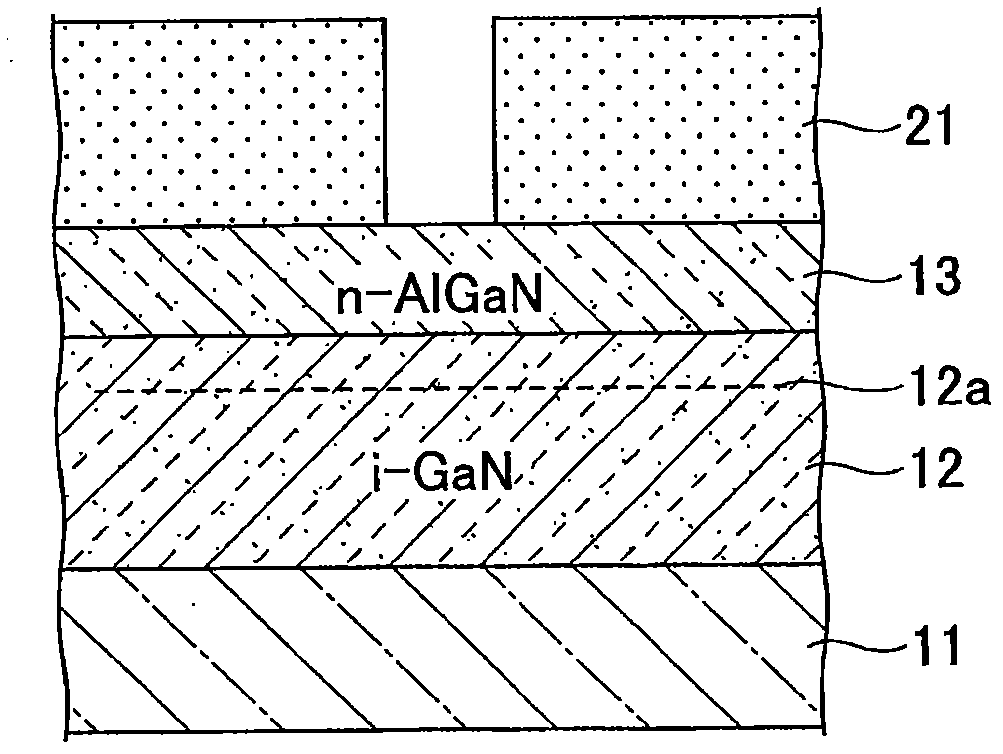

[0028] see figure 1 A semiconductor device 100 according to a first embodiment of the present invention is described. figure 1 It is a schematic diagram showing a semiconductor device 100 according to a first embodiment of the present invention. The semiconductor device 100 has semiconductor layers including an electron transport layer 12 and an electron supply layer 13 formed in this order on a substrate 11 . Substrate 11 is formed of a semi-insulating material such as SiC. The electron transport layer (to be the first semiconductor layer) 12 is formed of, for example, i-GaN. The electron supply layer (to be the second semiconductor layer) 13 is formed of, for example, n-AlGaN. Thus, a two-dimensional electron gas (2DEG) layer 12 a is formed in the electron transport layer 12 near the interface between the electron transport layer 12 and the electron supply layer 13 . Gate groove 22 is formed, for example, in electron supply layer 13 . Th...

no. 2 example

[0047] (semiconductor device)

[0048] see Figure 7 A semiconductor device 200 according to a second embodiment of the present invention is described. In the second embodiment, like elements are described using like reference numerals to those of the first embodiment without further description. Figure 7 It is a schematic diagram showing a semiconductor device 200 according to a second embodiment of the present invention. The semiconductor device 200 has a plurality of semiconductor layers including an electron transport layer 12 , an electron supply layer 13 , and a cap layer 14 sequentially formed on a substrate 11 . Substrate 11 is made of Si, for example. The electron transport layer (to be the first semiconductor layer) 12 is made of i-GaN, for example. The electron supply layer (to be the second semiconductor layer) 13 is made of, for example, n-AlGaN. Thus, a two-dimensional electron gas (2DEG) layer 12 a is formed in the electron transport layer 12 in the vicini...

no. 3 example

[0063] (semiconductor device)

[0064] see Figure 11 A semiconductor device 300 according to a third embodiment of the present invention is described. In the third embodiment, similar elements are described using similar reference numerals to those of the first and second embodiments without further description. Figure 11 It is a schematic diagram showing a semiconductor device 300 according to a third embodiment of the present invention. The semiconductor device 300 has a plurality of semiconductor layers including an electron transport layer 12 , an electron supply layer 13 , a protective layer 15 , a capping layer 16 , and a capping layer 14 which are sequentially formed on a substrate 11 . Substrate 11 is made of GaN, for example. The protective layer 15 is made of n-GaN. The cap layer 16 is made of i-AlN. The electron transport layer (to be the first semiconductor layer) 12 is made of i-GaN. The electron supply layer (to be the second semiconductor layer) 13 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com