Sub-wavelength surface plasma laser

A surface plasmon and laser technology, which is applied to the structure of optical waveguide semiconductors and other directions, can solve the problems of inability to balance mode field confinement capability and transmission loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

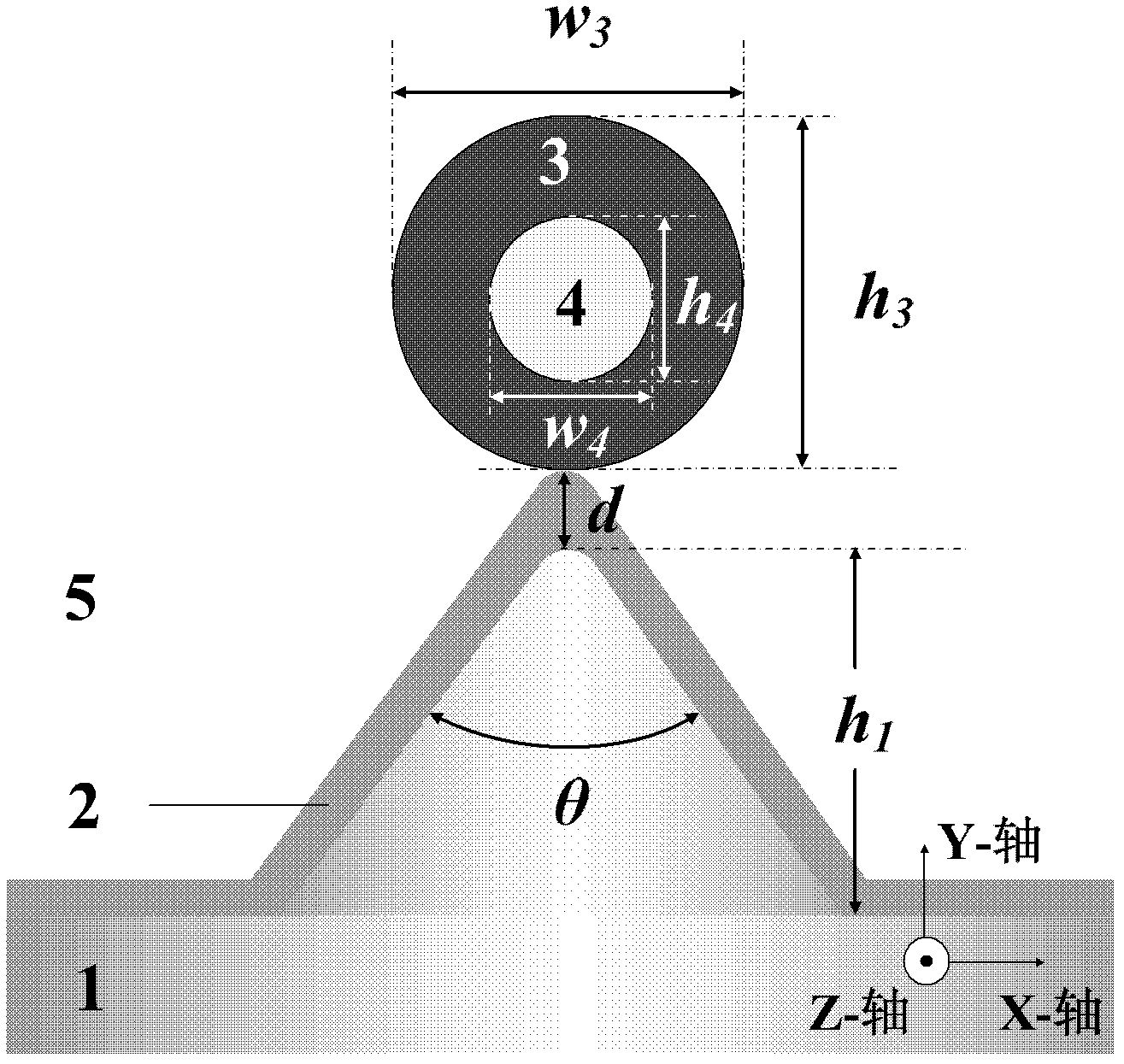

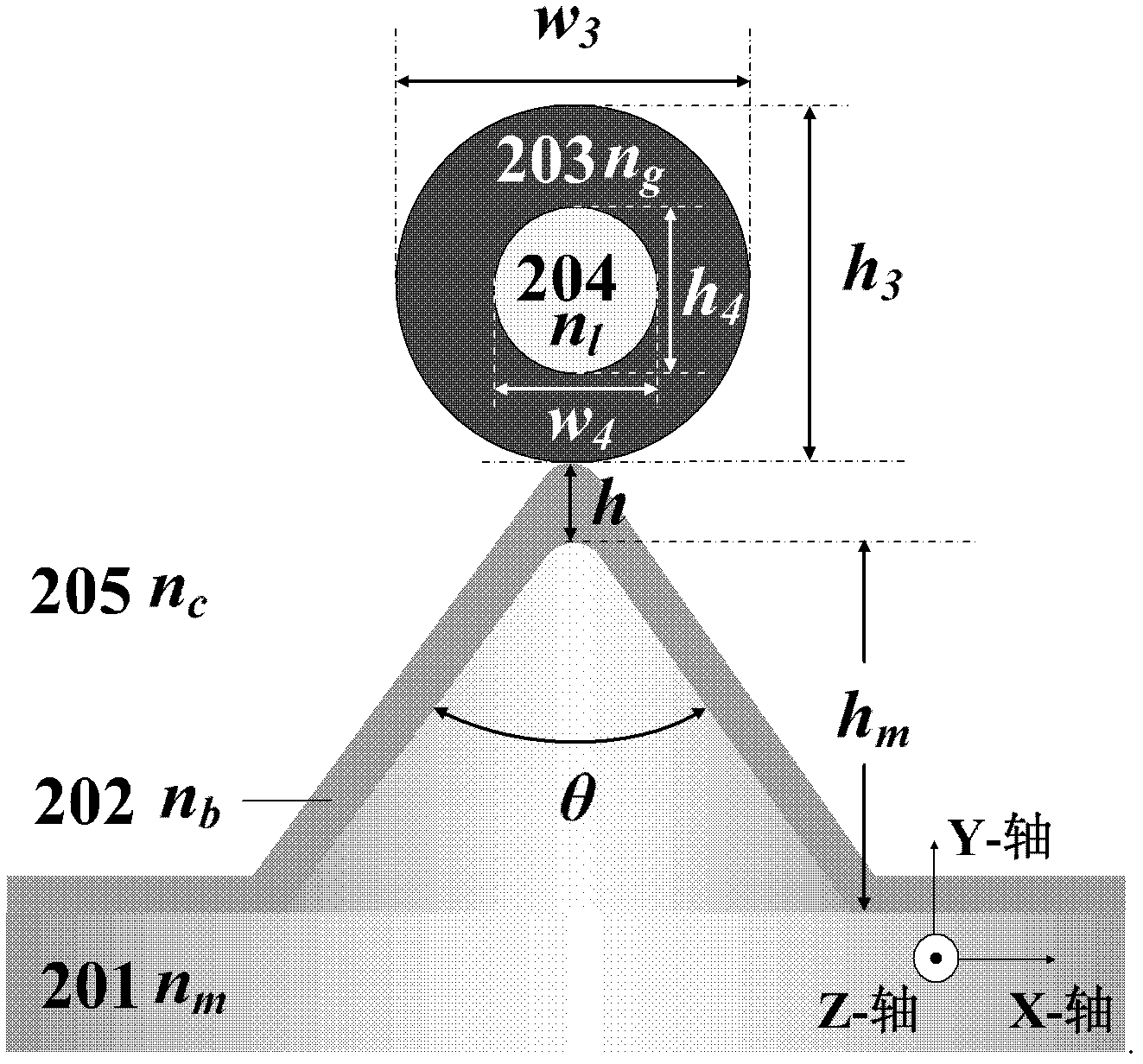

[0034] figure 2 is the cross-sectional structure diagram of the subwavelength surface plasmon laser described in the example. 201 is the metal base, n m Its refractive index, the inner vertex angle of the "∧"-shaped area is θ, and the height of the "∧"-shaped area is h m ; 202 is the medium buffer layer, n b is its refractive index, h is its thickness; 203 is a circular gain medium nanotube, n g is its refractive index, w 3 its width, h 3 Its height; 204 is the filling area in the center of the gain medium nanotube, n 1 is its refractive index, w 4 its width, h 4 Its height; 205 is the cladding, n c is its refractive index; the longitudinal (along the Z-axis direction) length of 201, 202, 203 and 204 is L.

[0035] In this example, the wavelength of the laser output light is 490nm, the material of 201 is silver, the real part of the refractive index at the wavelength of 490nm is -9.2, and the imaginary part is 0.3; the material of 203 is cadmium sulfide, and the real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com