Pay-off stand for motor compensating winding

A technology for compensating windings and pay-off racks, which is applied to electric components, manufacturing motor generators, electrical components, etc., and can solve the problem of electromagnetic wire outsourcing insulation damage, large footprint of pay-off racks, and cold work of flat copper wires inside electromagnetic wires. Hardening and other problems to ensure the insulation performance and improve the quality of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

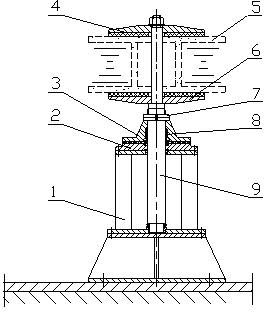

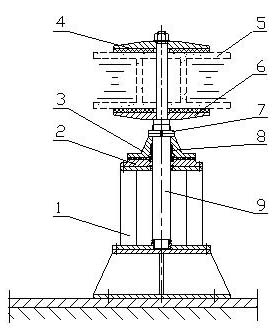

[0012] Such as figure 1 As shown, a pay-off rack rotating shaft 9 is fixed on the pay-off rack rotating shaft support frame 1, and the rotating shaft 9 is fixed on the support frame 1 through two sliding bearings and a plane thrust bearing, and an electromagnetic wire reel 5 is fixed on the upper end of the rotating shaft 9 , the upper and lower ends of the electromagnetic wire reel 5 are clamped and fixed on the rotating shaft 9 by the wire crimping disc 4 and the wire supporting disc 6 respectively, and can rotate together with the rotating shaft 9. Between them, rubber gaskets are lined between the electromagnetic wire reel 5 and the wire tray 6; a brake device is connected on the rotating shaft 9, and the brake device includes a friction disc 3 and a brake pad, and the friction disc 3 is connected to the shaft by a key. On the rotating shaft 9, a spring 8 is installed between the inner circle of the friction moving disk 3 and the rotating shaft 9, and the lower end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com