Permanent magnet harmonic motor

A harmonic motor, permanent magnet technology, applied in the direction of motors, synchronous motors with stationary armatures and rotating magnets, synchronous machines, etc. Load quality, simple assembly process, downsizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

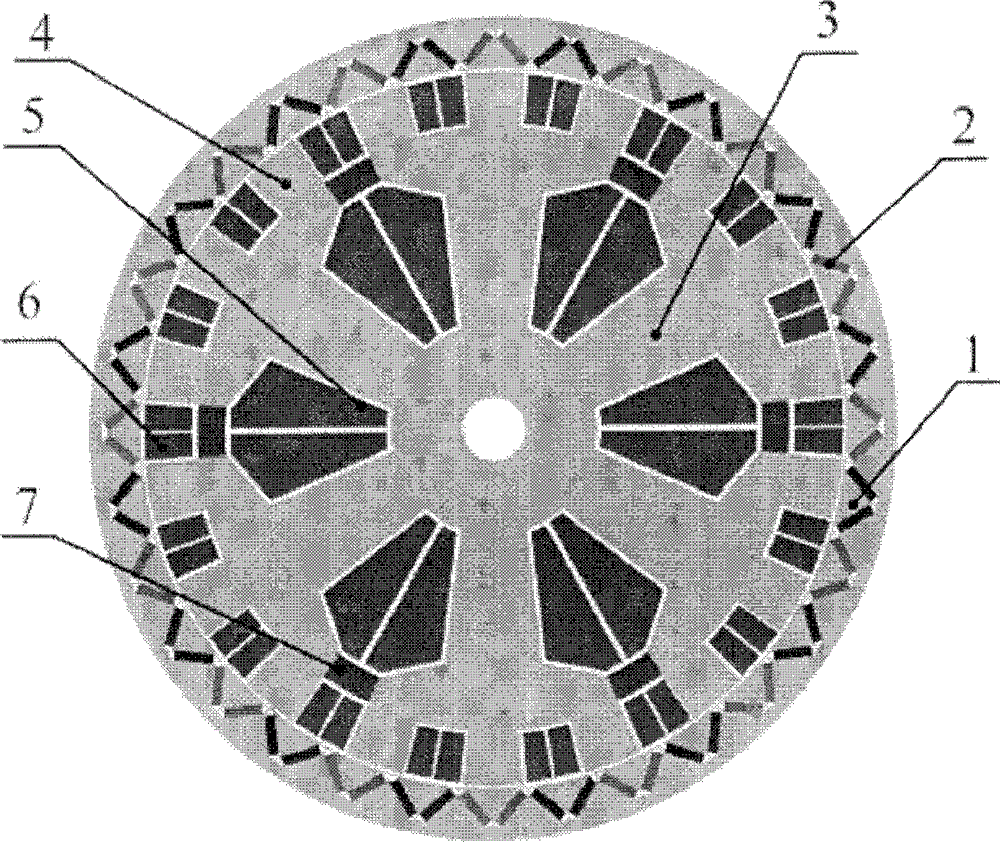

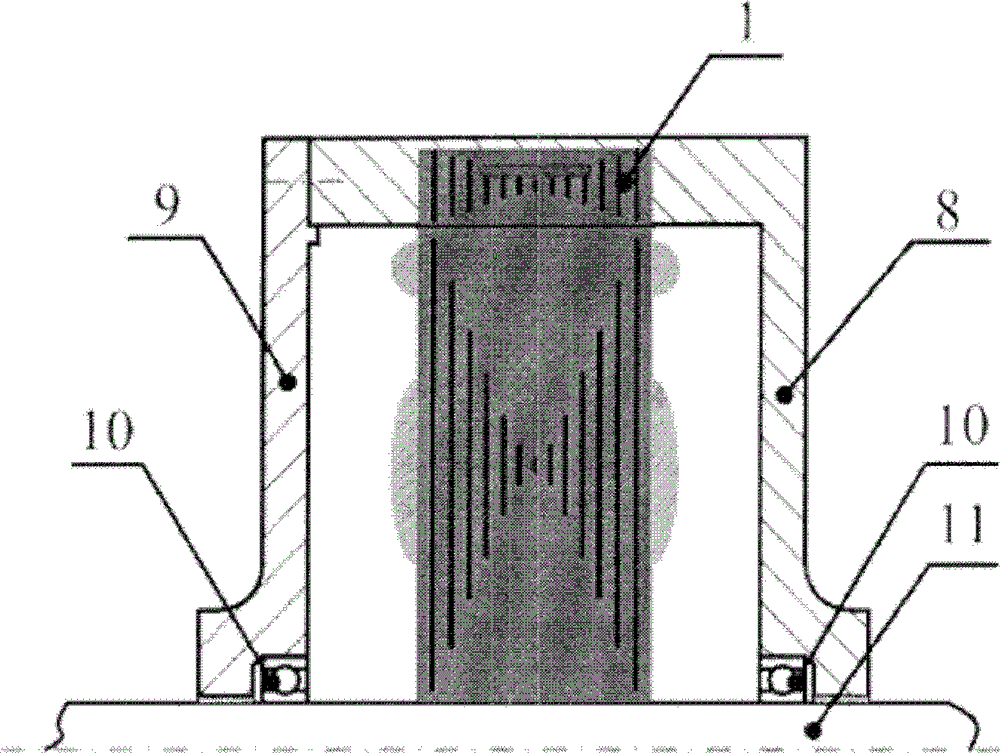

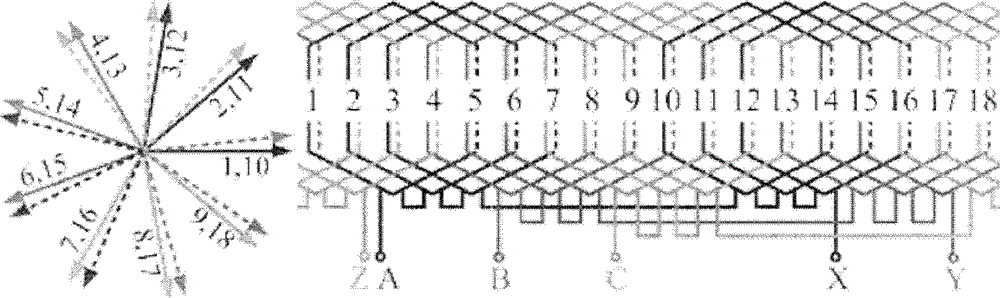

[0036] Such as figure 1 The shown permanent magnet harmonic motor comprises: a rotor mechanism 1, which is provided with several permanent magnets 2; the shape of the permanent magnets 2 can be many kinds, wherein, it is preferably rectangular; the permanent magnets 2 and There are many connection relationships of the rotor mechanism, among which, it is preferably embedded in the rotor mechanism. When the rotor rotates at a high speed, the permanent magnets are not easy to fall; in addition, the distribution of the permanent magnets 2 can have There are many kinds, among which, it is preferred to be V-shaped distribution, and every two adjacent V-shaped permanent magnets 2 have opposite magnetic poles; the harmonic motor also includes a stator mechanism 3, which cooperates with the rotor mechanism 1, wherein the stator mechanism There is an air gap between 3 and the rotor mechanism 1; a support mechanism 8 is provided, and a bearing assembly 10 is provided on the support mecha...

Embodiment 2

[0048] Such as Figure 5 and Figure 6 The difference between the permanent magnet harmonic motor shown in this embodiment and the motor in Embodiment 1 is that the rotor mechanism is an inner rotor mechanism, and the stator mechanism is an outer stator mechanism.

[0049] see Figure 6 , in this embodiment, the outer stator, the support mechanism 8 and the end cover 9 are respectively fixed on the outer ring of the bearing assembly 10 . The rotor is fixed on the shaft 11, and the supporting mechanism may be a cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com