Bias Current Control Method and Driving Circuit of Operational Amplifier

An operational amplifier, bias current technology, applied in differential amplifiers, DC-coupled DC amplifiers, instruments, etc., can solve problems such as disadvantages of electronic devices, and achieve the effect of saving power consumption, optimizing system performance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

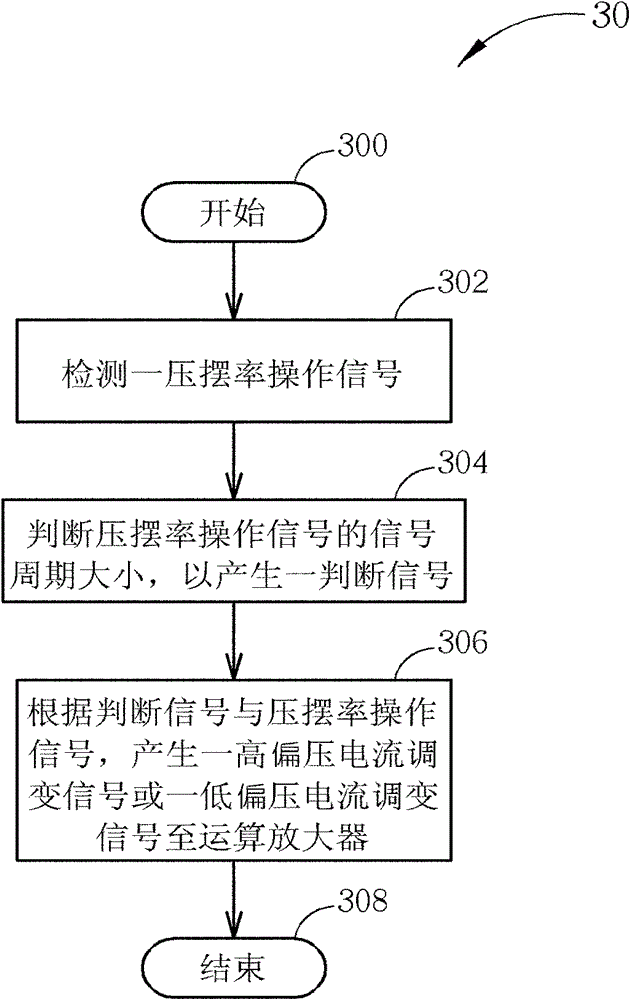

[0031] Please refer to image 3 , image 3 It is a schematic diagram of a bias current control process 30 for an operational amplifier according to an embodiment of the present invention. Process 30 includes the following steps:

[0032] Step 300: Start.

[0033] Step 302: Detect a slew rate operation signal.

[0034] Step 304: Determine the signal period of the slew rate operation signal to generate a determination signal.

[0035] Step 306: Generate a high bias current modulation signal or a low bias current modulation signal to the operational amplifier according to the determination signal and the slew rate operation signal.

[0036] Step 308: End.

[0037] According to the process 30, before the operational amplifier starts to drive the external load, the present invention can determine the signal period size of the detected slew rate operation signal to generate a corresponding determination signal. Next, according to the determination signal, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com