Ultrathin battery cover made of curved-surface carbon fiber material and manufacturing process of ultrathin battery cover

A carbon fiber material and manufacturing process technology, applied in the field of ultra-thin battery cover, can solve the problems of complex process, inability to achieve ultra-thin mobile phone structure, and inability to achieve ultra-thin, achieve strong pertinence, enhanced appearance and practical performance, glass fiber colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing:

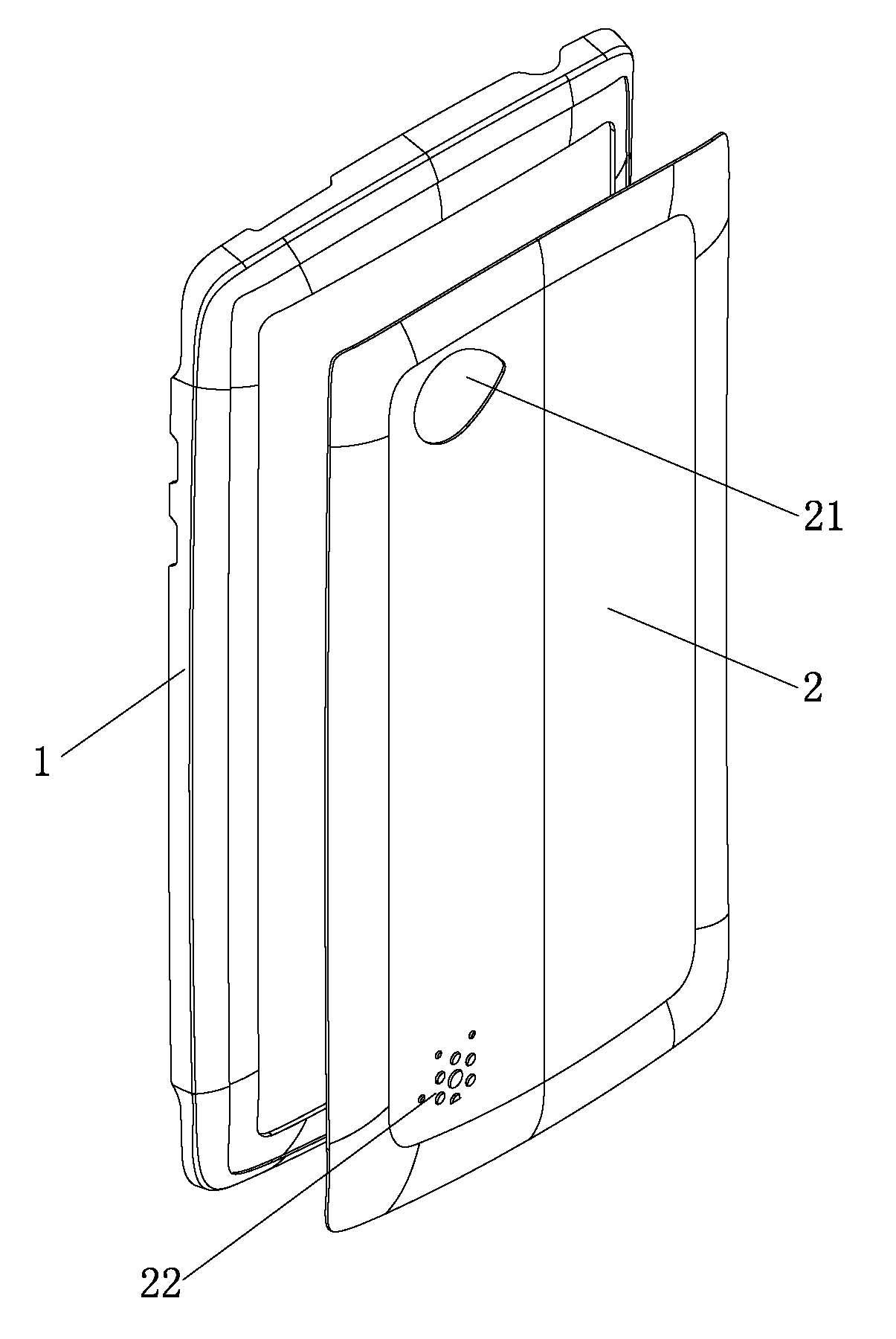

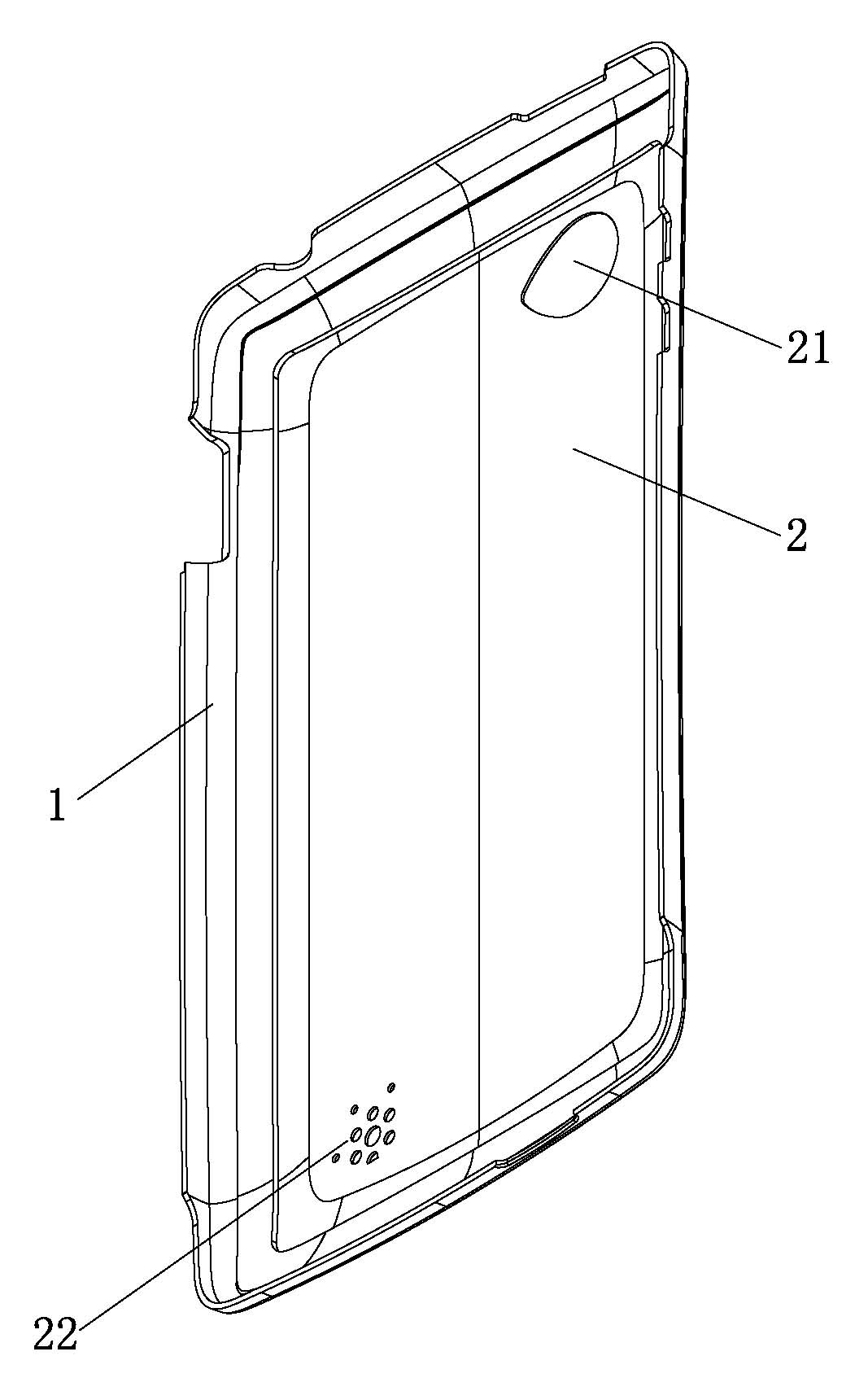

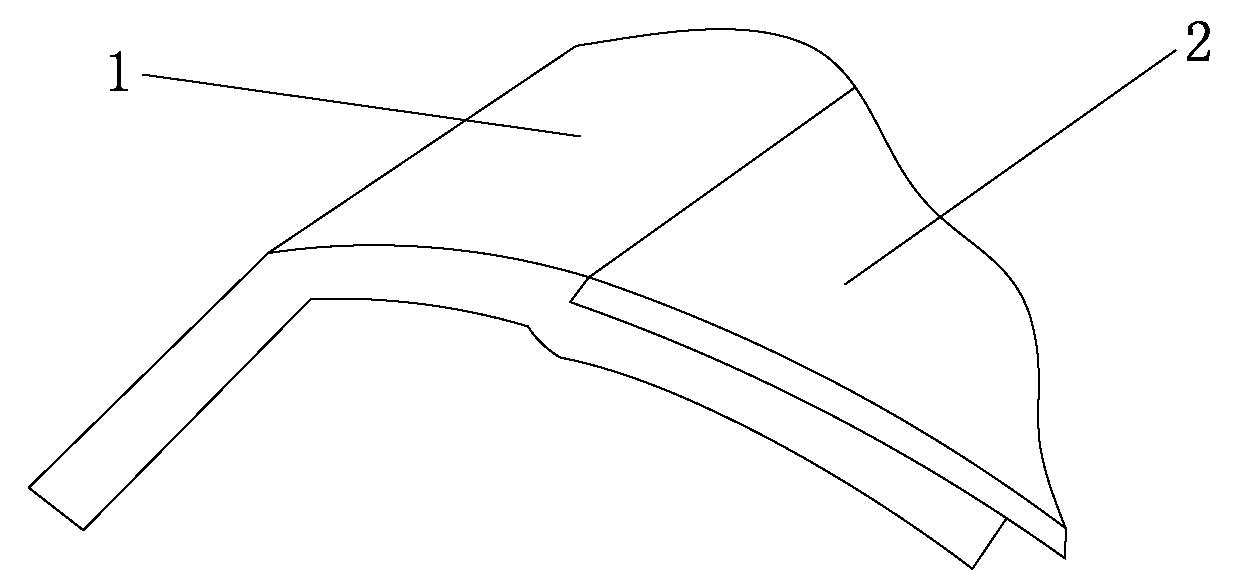

[0021] Please refer to the accompanying drawings, the ultra-thin battery cover made of curved carbon fiber material is composed of an injection molded frame 1 for the battery cover of a mobile phone, and a curved carbon fiber composite plate 2 set in the injection molded frame 1 and injected in the mold. The curved carbon fiber composite board 2 is provided with a speaker hole 22 and an outline of a camera avoidance hole 21 . The mobile phone battery cover is applied to the mobile phone whose battery cover cannot be plugged and unplugged.

[0022] The manufacturing process of the ultra-thin battery cover made of the curved carbon fiber material includes the following steps:

[0023] (1) Preparation of raw materials: Weave carbon fiber sheets into square carbon fiber silk made by a textile machine; then soak them in epoxy resin solution, heat them to a semi-cured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com