Electromagnetic heating coil plate

A technology of electromagnetic heating coils and coil disks, which is applied in the direction of coil devices and induction heating, etc., which can solve the problems of difficulty in dissipating heat at the jumper part, increase in preparation costs, and restrict the flexibility of winding operations, so as to simplify the structure and facilitate heat dissipation , to avoid the effect of heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

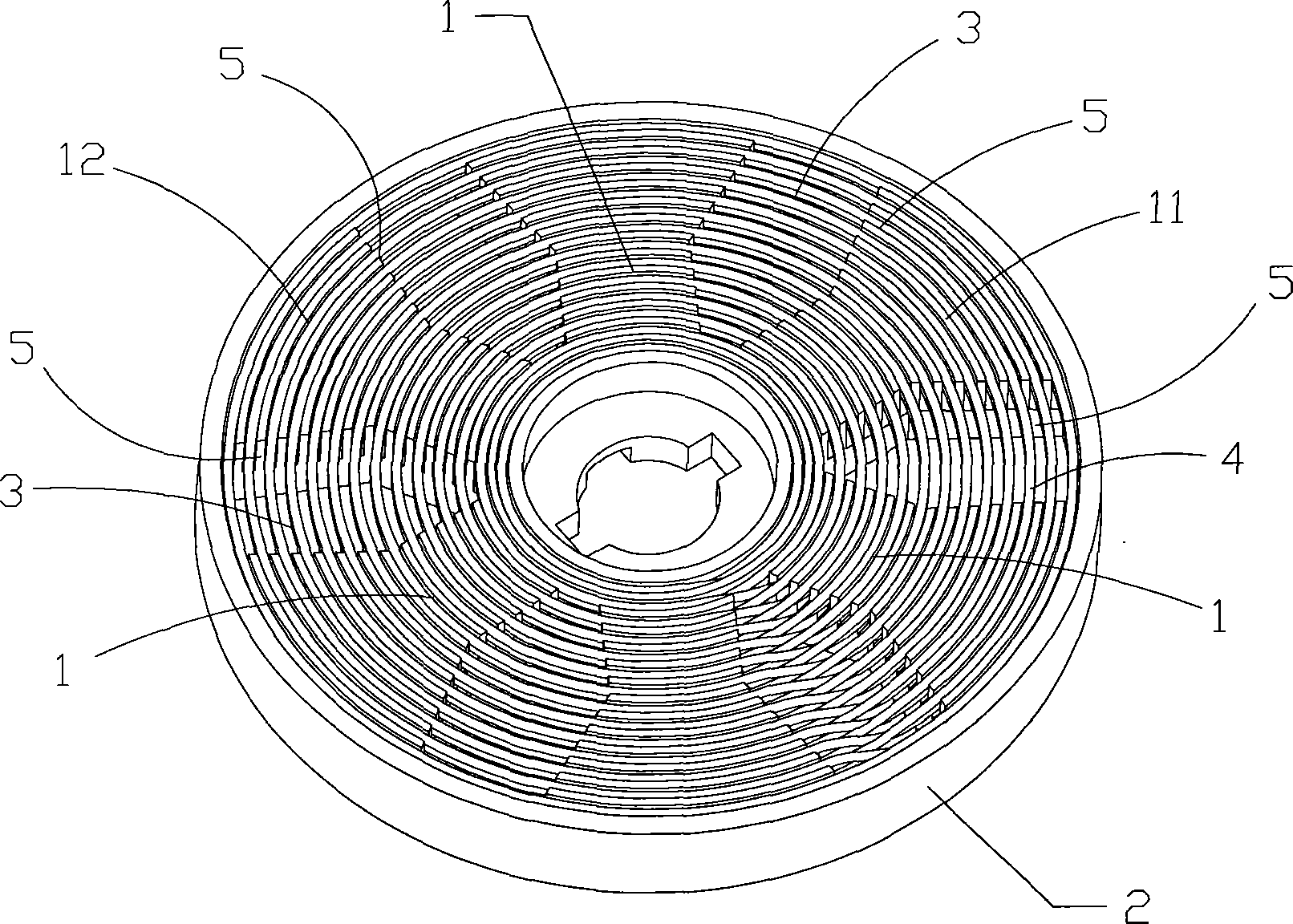

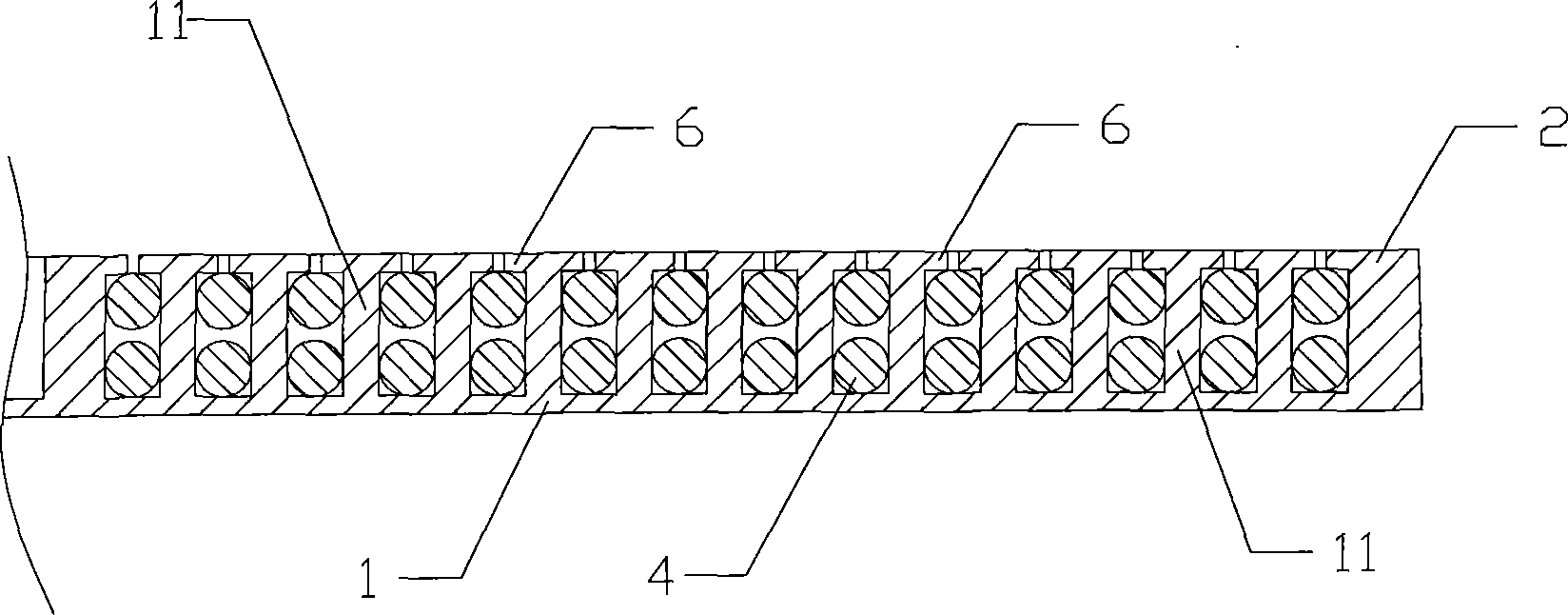

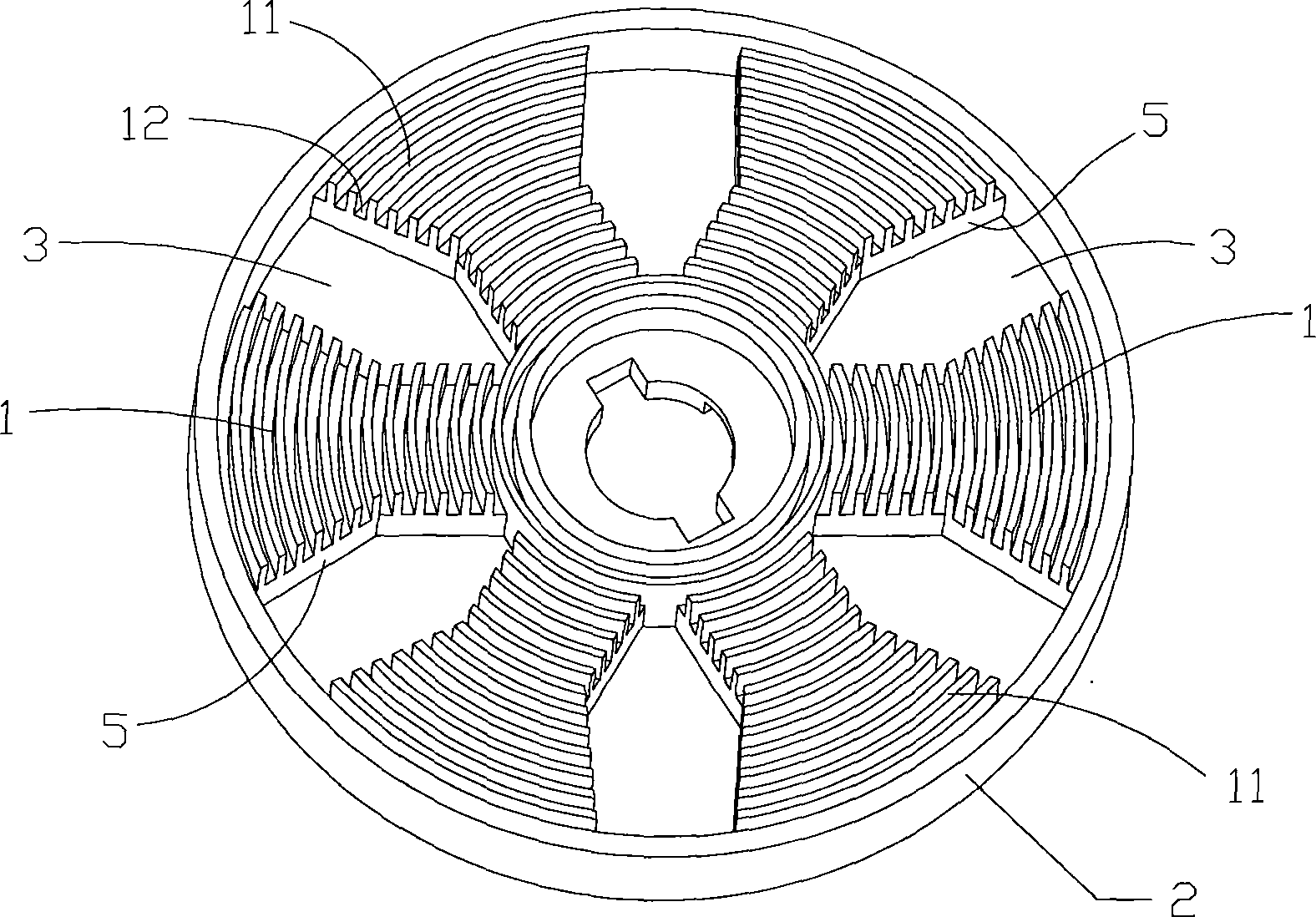

[0019] according to figure 1 and figure 2 As shown, it is the best embodiment of the present invention, the electromagnetic heating coil disk includes a coil disk support 2 with several winding parts 1, and the center of the winding part 1 layer is radially arranged on the coil disk support 2. The back side of the winding part 1 is provided with an accommodating groove, and a magnetic strip (not shown in the figure) is installed in the accommodating groove. A spacer cavity 3 is left between adjacent winding parts 1, such as figure 1 and image 3 As shown, the spacer cavity 3 can facilitate the heat dissipation of the enameled wire 4, and the wire slots 12 on the winding part 1 form a concentric circle structure together. The winding part 1 is provided with a number of baffles 11, and the baffles 11 are arc-shaped structures. Wire slots 12 are formed between adjacent baffle plates 11, and stoppers 6 are also arranged on the baffle plate 11, such as figure 2 As shown, duri...

Embodiment 2

[0023] see Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is: the enameled wire 4 of this embodiment is a single-layer structure, and at the same time, the changing positions of the enameled wire 4 of this embodiment are not concentrated in the same interval cavity 3. Instead, the variable winding between adjacent wire slots 12 is carried out on any interval cavity 3 at will. The enameled wire 4 is arranged in the same way on the winding part 1. Its winding method is as follows:

[0024] The first circle is wound first, and then the second circle is wound through one of the spacer cavities 3, and then the third circle is wound through another spacer cavity 3, and the fourth circle, the fifth circle..., According to this method, the electromagnetic heating coil disc described in the cost embodiment is wound.

[0025] Embodiments of the present invention include but are not limited to the above two embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com