Packaging bag for transportation

A technology of packaging bags and packaging materials, applied in the field of packaging bags for transportation, which can solve the problems of unsuitable absorbent materials, unfavorable mass production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An example of an aspect of the shipping packaging bag for carrying out the present invention will be described in detail with reference to the drawings.

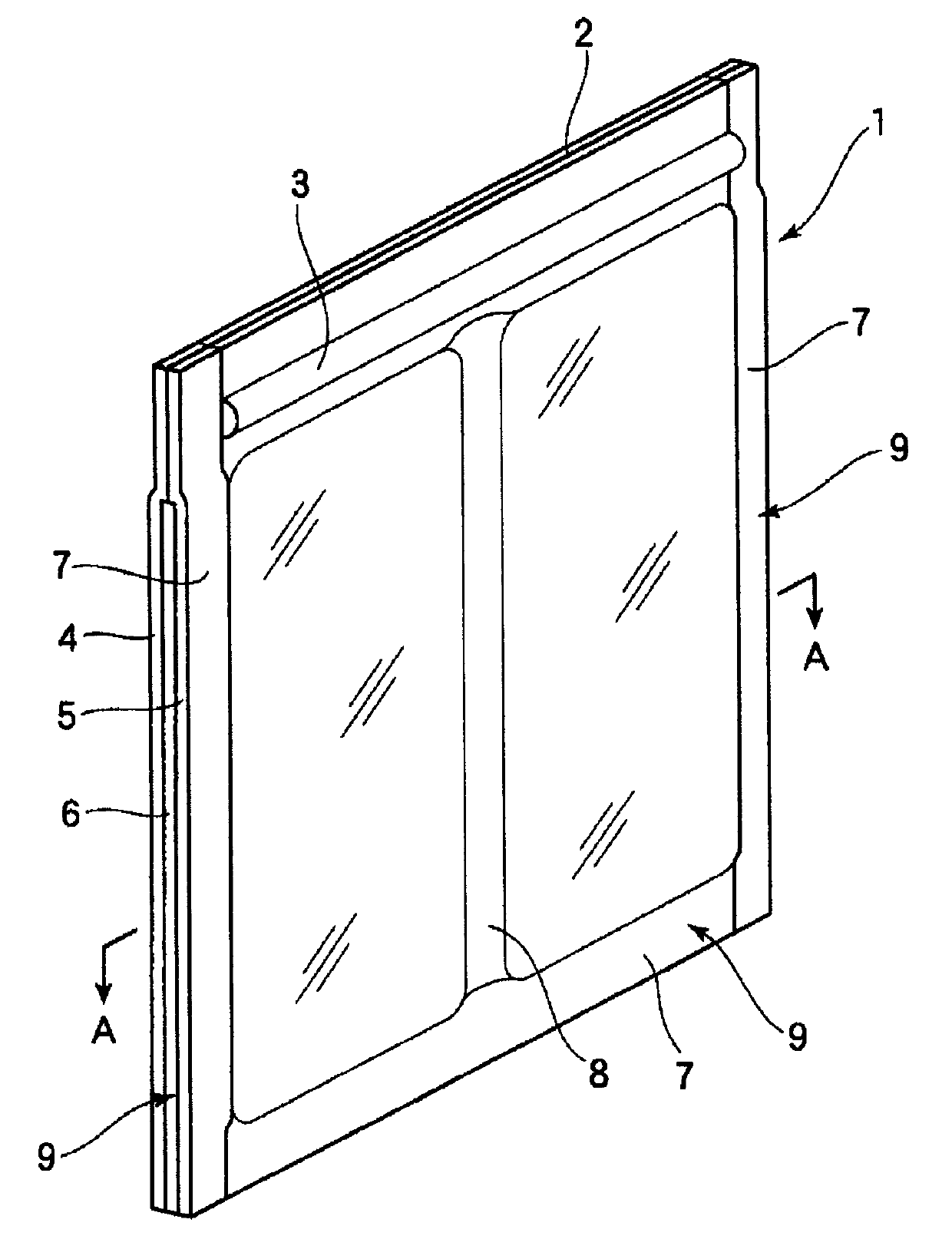

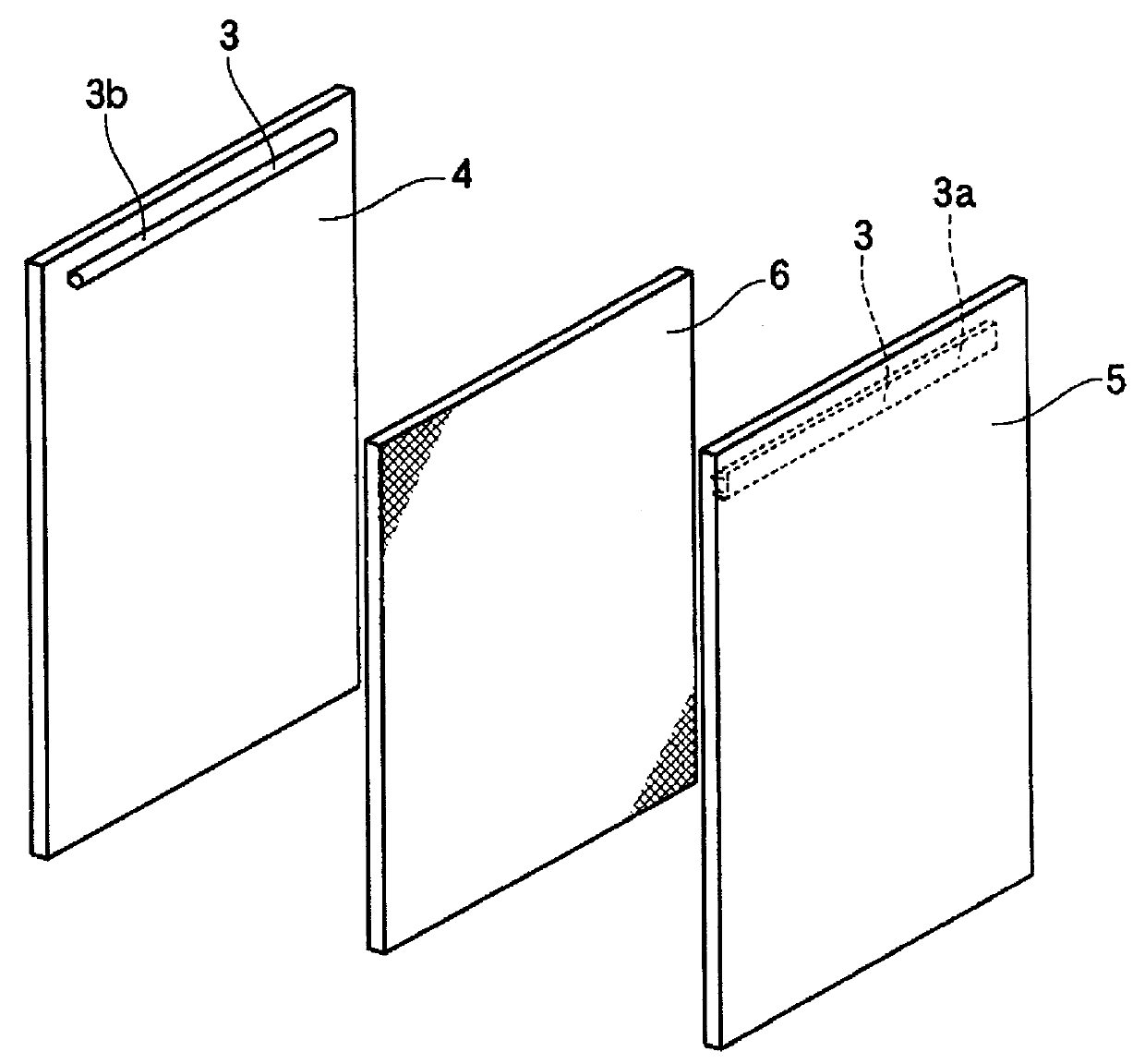

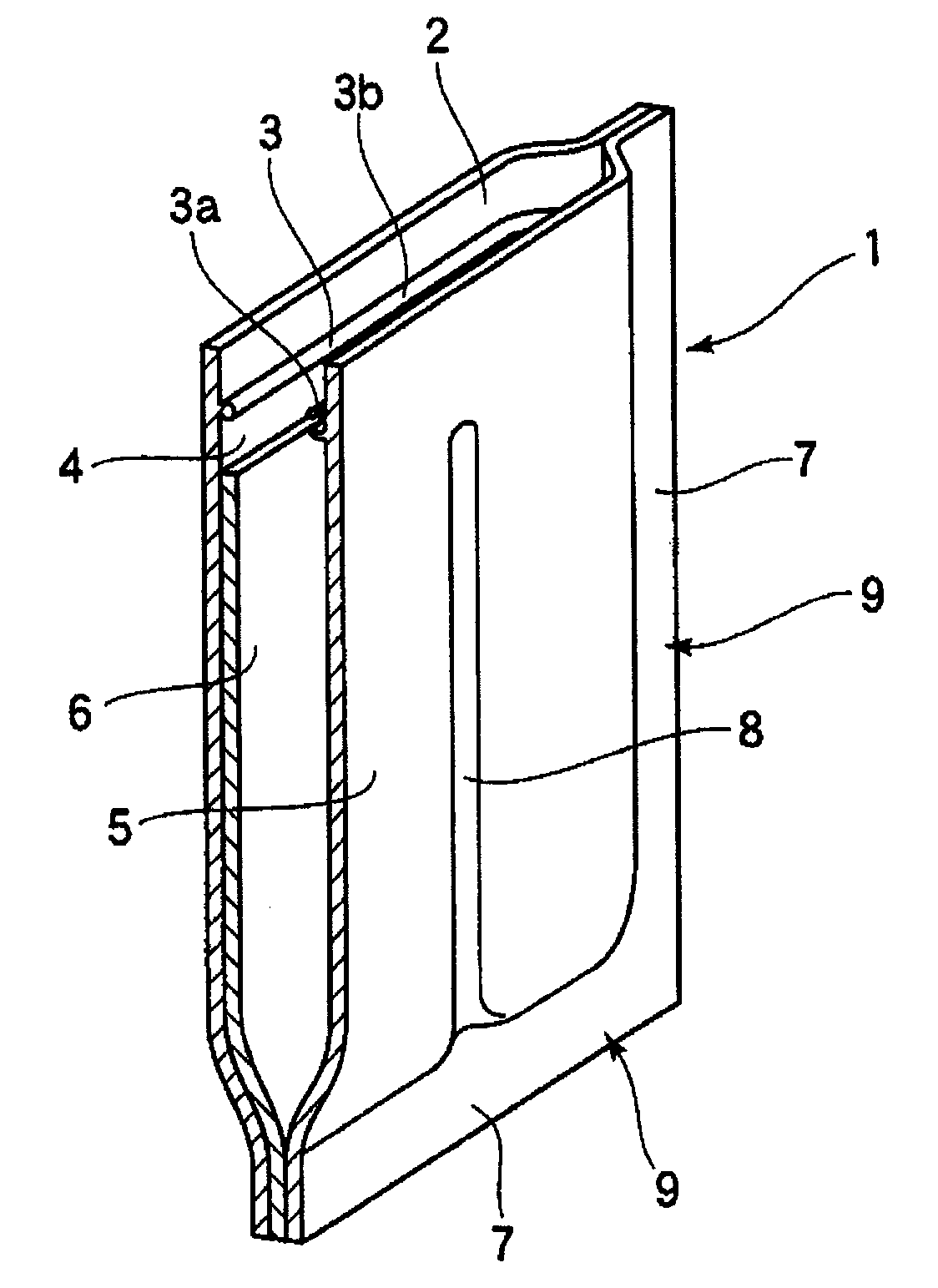

[0034] Figure 1 to Figure 3 An example of implementation of the shipping packaging bag of the present invention is shown, figure 1 is a perspective view showing the shipping packaging bag of the present invention, figure 2 yes figure 1 An exploded perspective view of the shipping bag of image 3 yes figure 1 The longitudinal sectional view of the unsealed state of the shipping packaging bag, Figure 4 yes figure 1 A-A line cross-sectional view.

[0035] The shipping packaging bag of this example is configured such that the opening 2 of the rectangular bag body 1 heat-sealed on three sides has an openable and closable sealing portion 3 . In the bag 1 described above, an absorbent material 6 is sandwiched between two packaging materials 4 and 5 made of a thermoplastic synthetic resin film, and an edge 7 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com