Steel pipe-concrete composite pile, process for production of the pile, and steel pipe for use in steel pile-concrete composite pile

A technology of concrete-filled steel tubes and a manufacturing method, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, and can solve the problems of no representation of concrete-filled steel tube composite piles, the reduction of strength and the complexity of increase and decrease of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0094] Embodiment 1 of the present invention will be described as Examples 1 and 2 shown below.

Embodiment 1

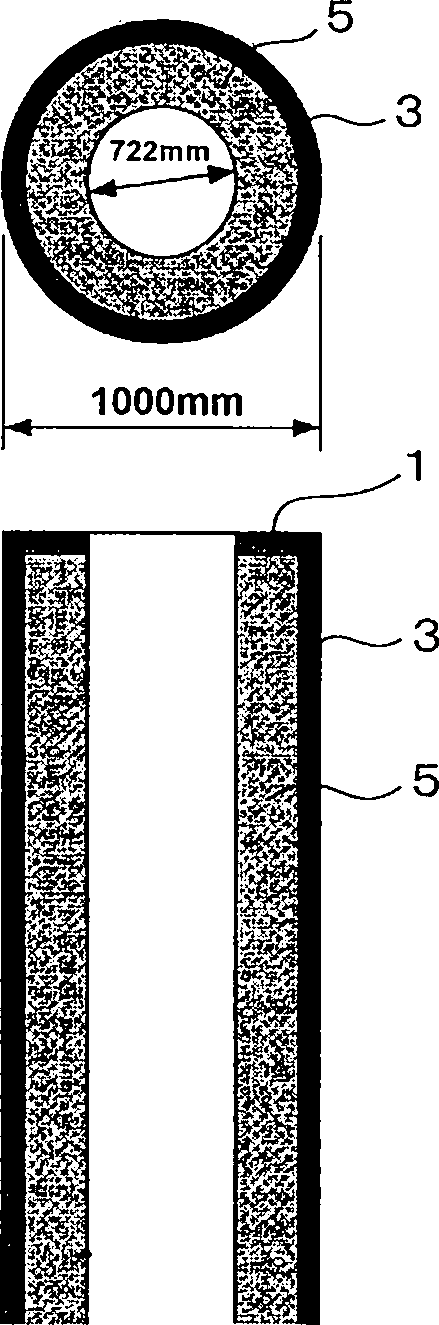

[0096] FIG. 1 is an explanatory diagram for explaining a steel pipe concrete composite pile according to the present invention, FIG. 1( a ) shows Example 1, and FIG. 1( b ) shows a conventional example as a comparative example.

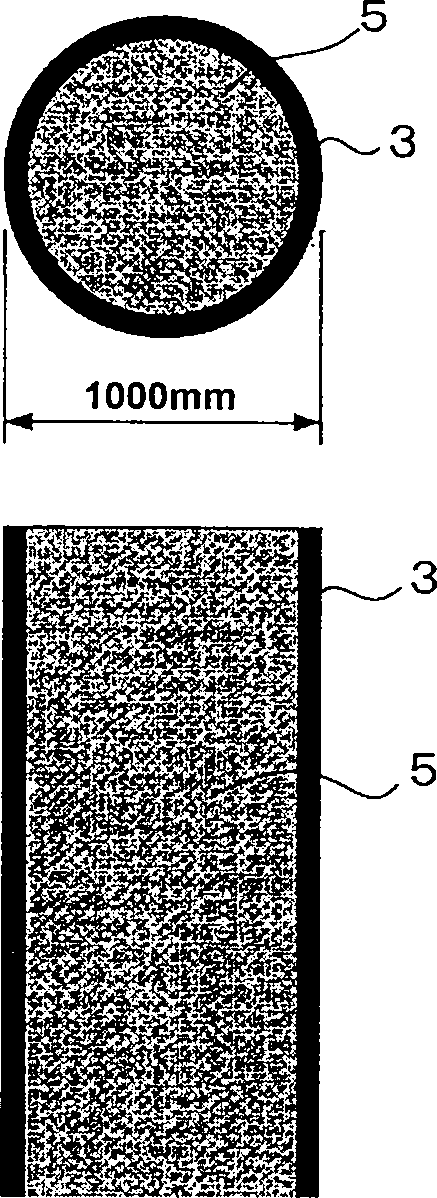

[0097] Example 1 shown in FIG. 1(a) shows that the inner surface of a steel pipe 3 provided with an end plate 1 at the upper end is lined with concrete 5, and the center is formed hollow in the "steel pipe wound concrete pile (SC pile)", An example of using a high-strength steel pipe is steel pipe 3 with a diameter of 1000 mm, a wall thickness of 9 mm, and a design yield strength of 485 N / mm. 2 The material and concrete 5 use a compressive strength of 100N / mm 2 Examples of materials.

[0098] In addition, in the conventional example shown in FIG. 1( b ), it is shown that a material having a strength similar to that of Example 1 is used as a material having a strength conventionally used as a "steel tube wound concrete pile (SC pile)" To determine th...

Embodiment 2

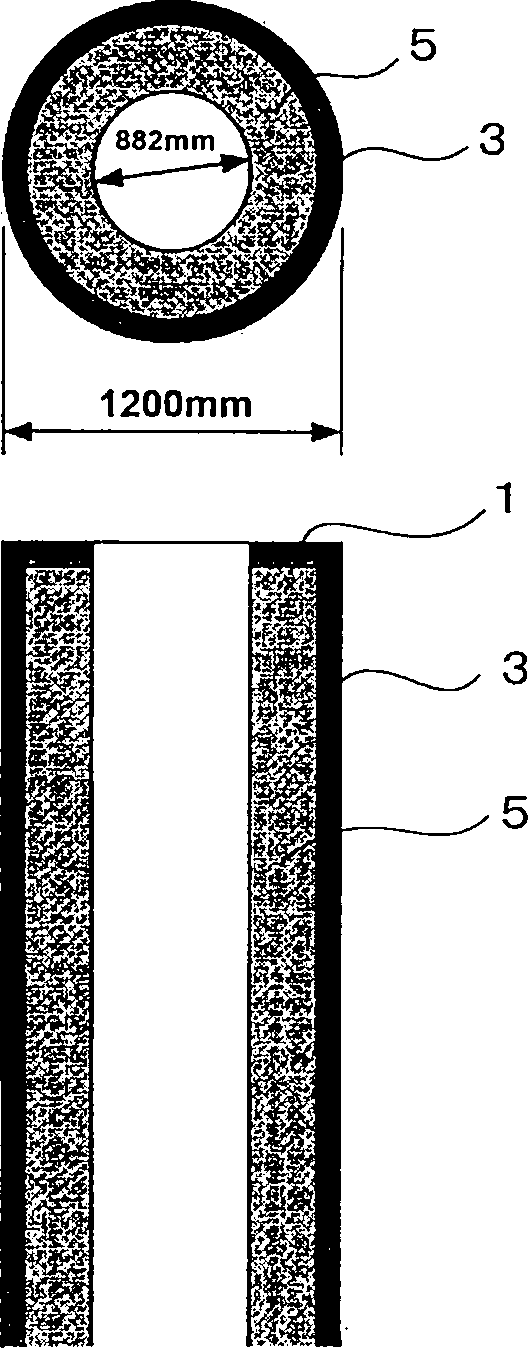

[0106] FIG. 2 is an explanatory diagram for explaining another concrete-filled steel pipe composite pile according to the present invention, FIG. 2( a ) shows Example 2, and FIG. 2( b ) is a conventional example as a comparative example.

[0107] Example 2 shown in FIG. 2( a ) is an example showing a case where a high-strength steel pipe is used in a "concrete-filled steel pipe pile" in which the inner surface of a steel pipe 3 is filled with concrete 5 . 19mm, design yield strength 355N / mm 2 The concrete piled on-site has a compressive strength of 75N / mm 2 Examples of materials.

[0108] In addition, in the conventional example shown in FIG. 2( b ), it is shown that the strength of the material used as the conventional "concrete-filled steel pipe pile" is used, and the cross-sectional strength of the same level as that of Example 2 is determined. Examples of specification parameters. In this conventional example, steel pipe 3 is used with a diameter of 1200 mm, a wall thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com