Robot with workpiece lifting device

A lifting device and work piece technology, applied in the field of robots, can solve the problems affecting the walking speed of the follower, etc., and achieve the effects of simple structure, flexible operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

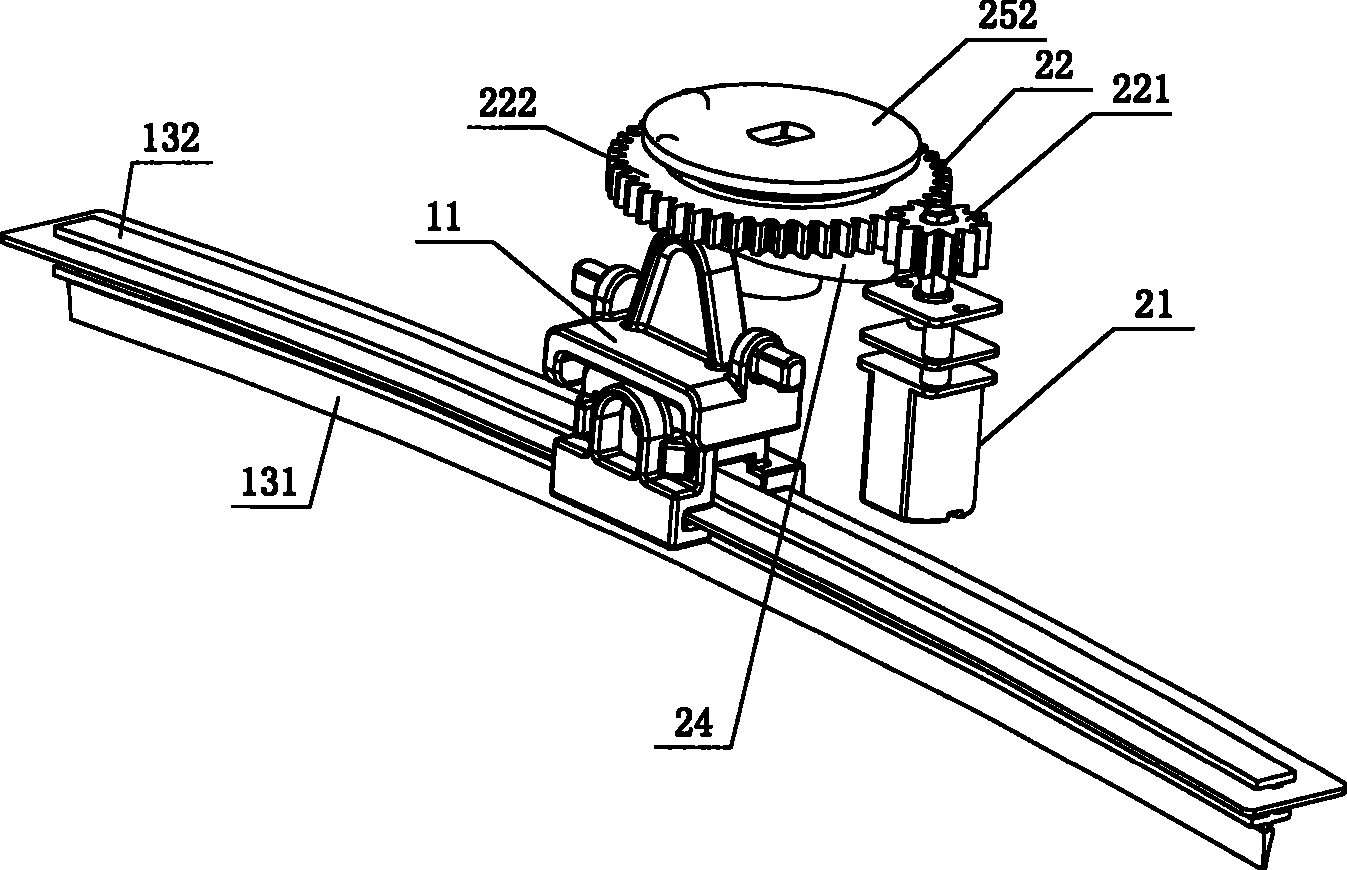

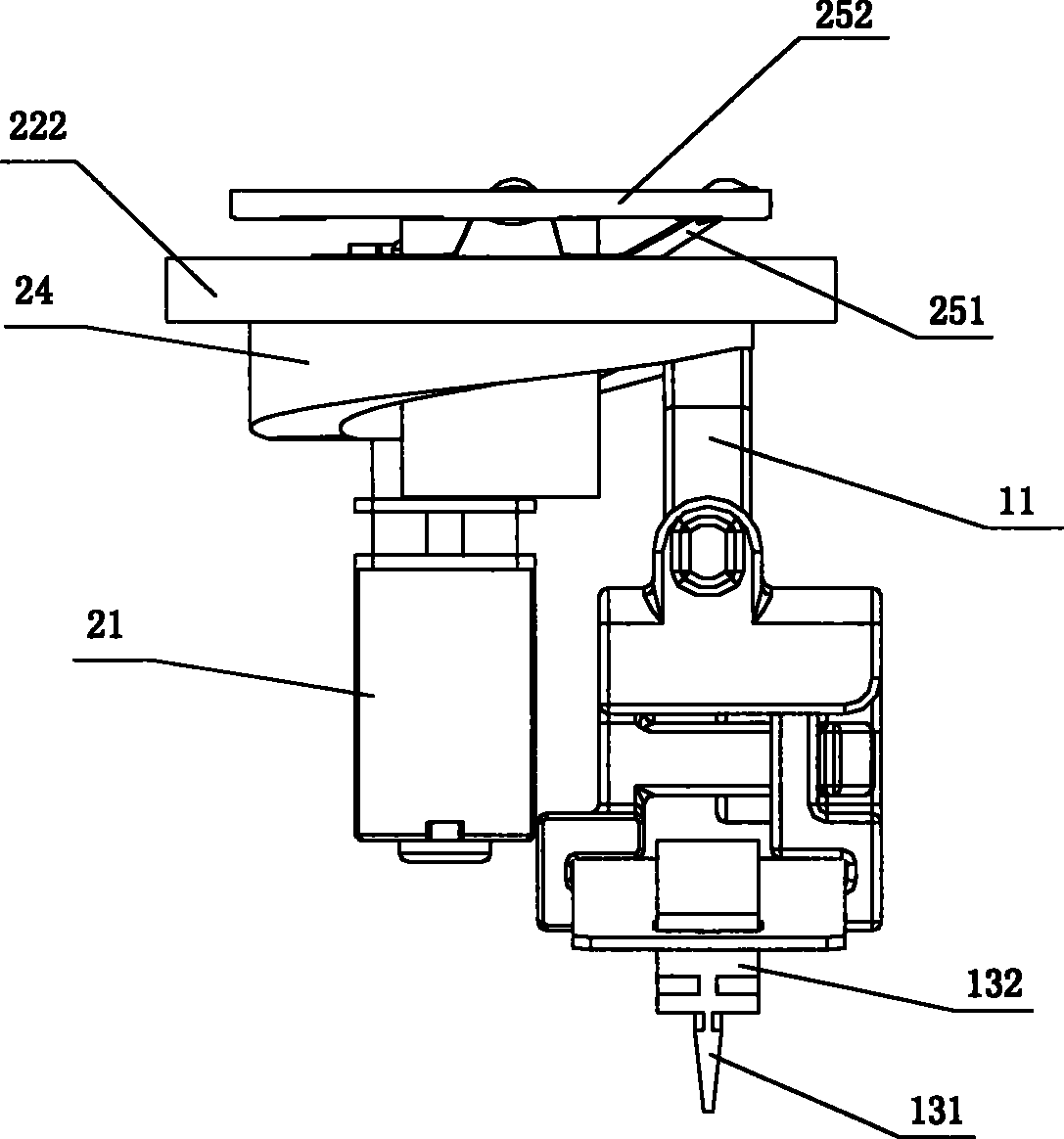

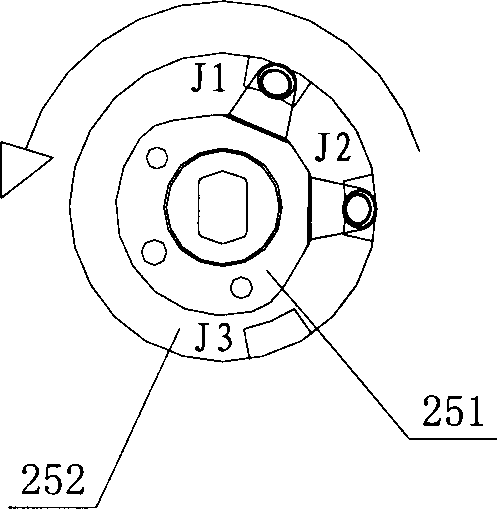

[0021] figure 1 , figure 2 They are schematic diagrams of the overall structure and plane structure of the workpiece lifting device of the robot of the present invention, respectively. Such as figure 1 and combine figure 2 As shown, the present invention provides a robot with a workpiece lifting device, including a robot body. The robot body is provided with a workpiece lifting device, including a workpiece and a lifting drive assembly. The lifting drive assembly includes a drive Motor 21, the rotating part 22 that is connected on the driving shaft of drive motor 21, and rotating part 22 is provided with inclined cam 24, and above described working part is provided with fixed frame 11, and this fixed frame 11 is movably connected in the robot body, and this The top of the fixed mount 11 abuts against the inclined surface on the side below the inclined cam 24 . In order to obtain a suitable rotational speed, a large gear 222 is provided on the rotating member 22 , and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com