Fluid ejection devices, medical equipment

A technology of fluid jetting and fluid, which is applied in the direction of fluid jetting scalpel, medical science, surgery, etc., and can solve problems such as unresection or incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

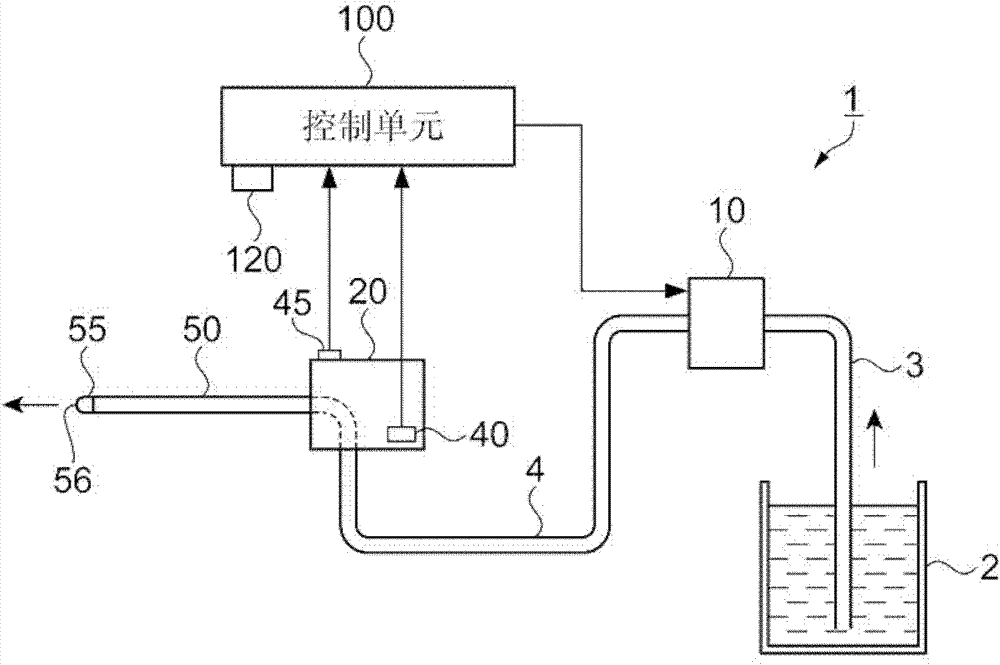

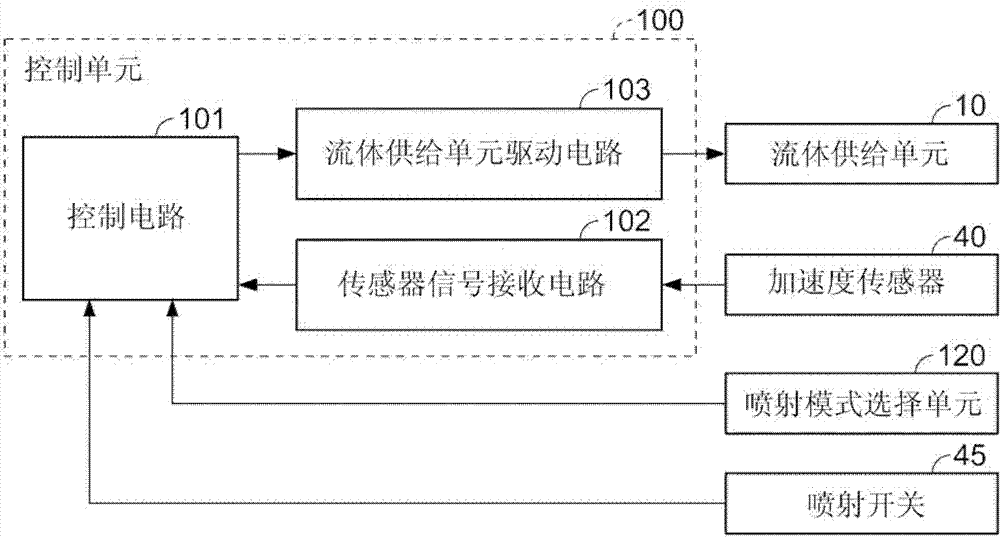

[0040] figure 1 It is a configuration diagram showing the outline of the fluid ejection device 1 of the first embodiment. in figure 1 Here, the fluid ejection device 1 is composed of the following parts: a fluid supply unit 10 that sucks fluid from a fluid container 2 containing fluid via a first connecting pipe 3; a fluid ejection pipe 50 that ejects the fluid supplied from the fluid supply unit 10; 2 A connecting pipe 4, which connects the fluid injection pipe 50 and the fluid supply unit 10; and a control unit 100, which controls the injection of fluid.

[0041] Here, the fluid supply unit 10 is a pump, and the form of the pump is not particularly limited. At the end of the fluid ejection tube 50, a nozzle 55 with a fluid ejection opening 56 with a reduced diameter of the flow path is inserted. The nozzle 55 further increases the supply pressure of the fluid supply unit 10, enabling high-speed ejection from the fluid ejection opening 56 . Therefore, the fluid ejection tube 5...

Embodiment approach 2

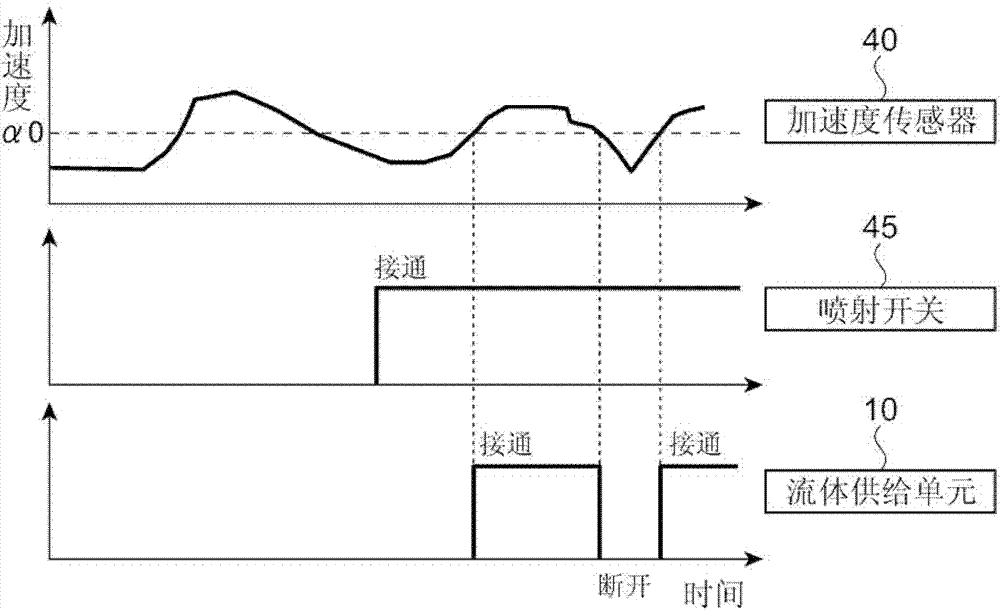

[0064] Next, a fluid ejection device 1 and a fluid ejection control method of Embodiment 2 will be described. In contrast to the case where the fluid injection in the first embodiment described above is a continuous flow, the feature of the second embodiment is a pulse flow.

[0065] Figure 5 It is a configuration diagram showing the outline of the fluid ejection device 1 of the second embodiment. in Figure 5 Here, the fluid ejection device 1 is composed of the following parts: a fluid supply unit 10 that sucks fluid from a fluid container 2 containing fluid via a first connecting pipe 3; and a pulsation generating part 30 that pulsates the fluid supplied from the fluid supply unit 10 The fluid ejection pipe 50, which communicates with the pulsation generating portion 30; the second connecting pipe 4, which connects the fluid supply unit 10 and the pulsation generating portion 30; and the control unit 100, which controls the ejection of the fluid.

[0066] Here, the fluid supply...

Embodiment approach 3

[0100] Next, a fluid ejection device of Embodiment 3 will be described. In the second embodiment described above, the injection of the fluid is controlled based on the signal of the pulse injection switch 46, the information of the injection pattern, and the detection signal of the acceleration sensor 40. In contrast, the third embodiment is different in that it has an information output unit. The output of the information output unit is controlled by the information of the injection mode and the detection signal (operation acceleration) of the acceleration sensor 40. Therefore, the description will focus on the differences.

[0101] Picture 11 It is a configuration explanatory diagram showing the main configuration of the control unit 100 of the third embodiment. In addition, parts having the same functions as those in the second embodiment are given the same reference numerals, and their description is omitted.

[0102] The control unit 100 has: a control circuit 110 that perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com