Automatic feeding system and method

An automatic feeding and formulation technology, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as wrong mixture, fireproof boards are not environmentally friendly, unfavorable formula confidentiality, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

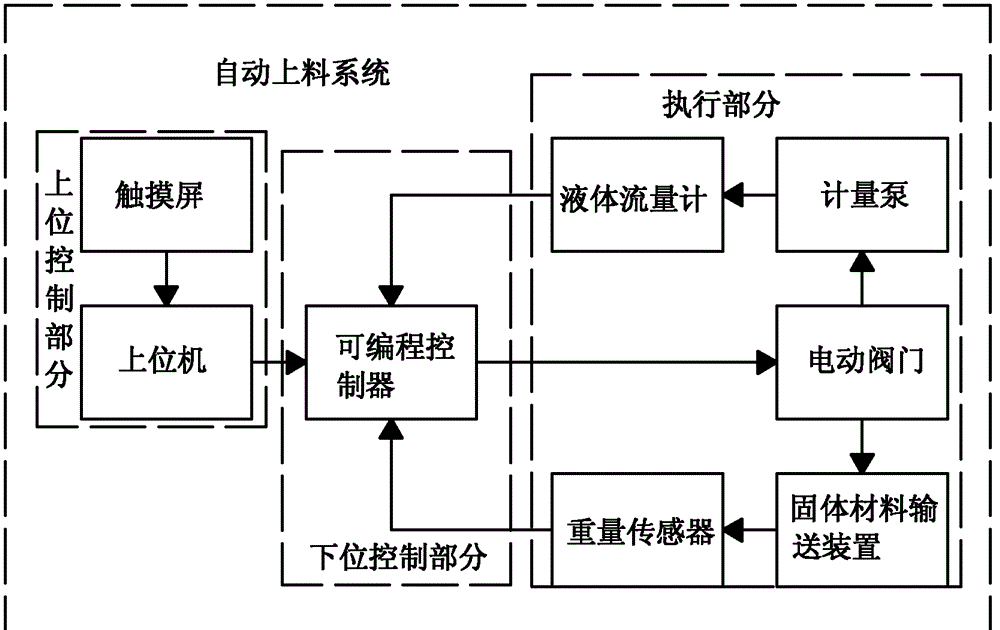

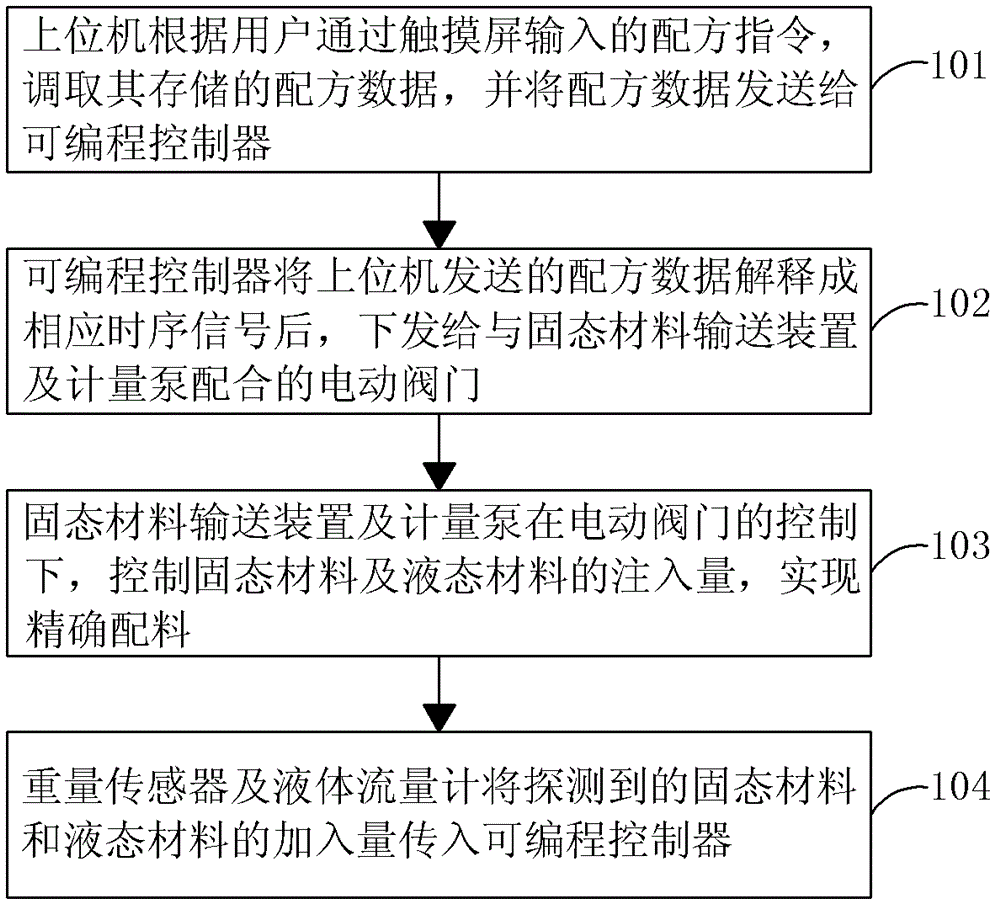

[0019] The present invention will be further described below in conjunction with drawings and embodiments. Please refer to figure 1 as shown, figure 1 It is a block diagram of the automatic feeding system of the present invention.

[0020] In this embodiment, the automatic feeding system includes: an upper control part, a lower control part, and an execution part; the upper control part includes: a host computer and a touch screen; the lower control part includes: a programmable controller; the lower control part Including: a weight sensor, a liquid flow meter, a solid material conveying device, a metering pump, and an electric valve matched with the solid material conveying device and the metering pump.

[0021] Both the touch screen and the host computer are connected to the monitoring bus. Since the formulas of the materials for producing fireproof boards are given corresponding formula numbers, the selection of the corresponding formula can be completed by selecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com