Method for controlling computer programming through injection molding machine by using electrical output action sequence diagrams

A technology for outputting actions and controlling computers, applied in the direction of program control devices, etc., to achieve the effect of reducing professional requirements, reducing professional requirements, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

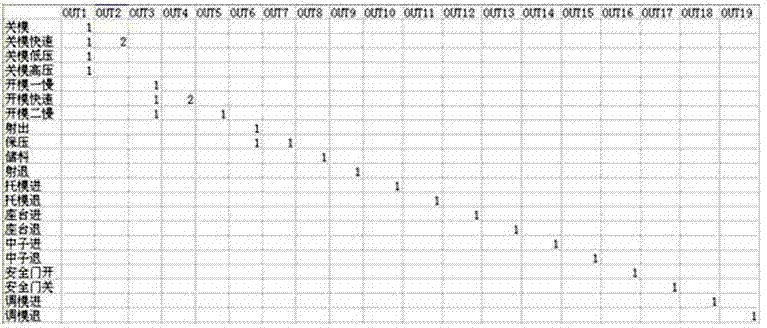

Embodiment 1

[0017] Embodiment 1: design a special compiling software and be installed on the PC computer, run this software, design a piece of electrical output action sequence diagram on the interface of this software (see figure 1 ), the content in the column is the name of the action controlled by the injection molding machine, and the content in the horizontal column is the output point number of the injection molding machine. After the design is finished, press the compile or save command button, the compiling software will automatically compile the output point switch conditions corresponding to each action set in the electrical output action sequence diagram into a configuration file that can be downloaded to the host, and then the configuration file can be downloaded to the host through USB, network , RS485 or RS232 and other ways to download to the computer control host of the injection molding machine, the host can make corresponding processing on the output point switch of the i...

Embodiment 2

[0018] Embodiment 2: The designer directly operates on the control panel of the injection machine control computer, and designs an electrical output action sequence chart on the control panel ( figure 1 ), the content in the column is the name of the action controlled by the injection molding machine, and the content in the horizontal column is the output point number of the injection molding machine. Set the switch status of the output point corresponding to each action in the electrical output action sequence diagram through the panel, and after saving the data set in the electrical output action sequence diagram through the panel, the control panel of the injection machine control computer will automatically download the configured data In the main control computer of the injection molding machine, the programming of the DA output channel has been completed at this point, and the host computer of the control computer can perform corresponding processing on the output point s...

Embodiment 3

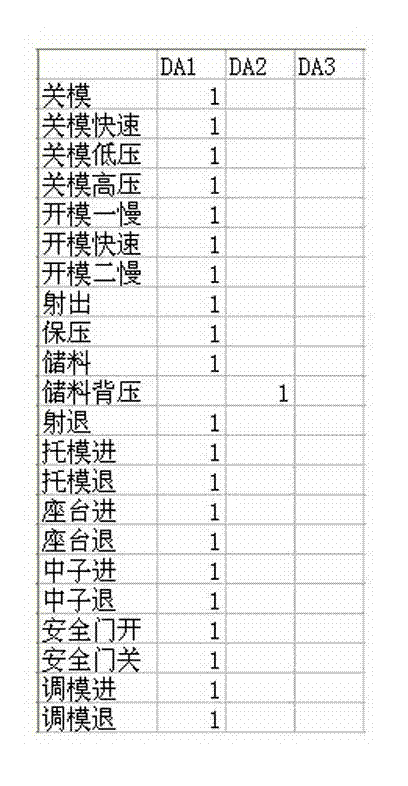

[0020] Embodiment 3: design a special-purpose compiling software and be installed on the PC computer, run this software, design a piece of electrical output action sequence diagram on the interface of this software (see figure 2 ), the content in the column is the name of the action controlled by the injection molding machine, and the content in the horizontal row is the DA output channel number of the injection molding machine. After the design is completed, press the compile or save command button, and the compiling software will automatically set each Generate a configuration file for the DA output channel switch corresponding to the action, and then update the configuration file of the electrical output action sequence diagram to the computer control host of the injection molding machine through USB, network, RS485 or RS232, etc., and the host can follow the electrical output action sequence The requirements in the figure correspond to the DA output channel of the injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com