Stacking machine for Z-shaped steel

A technology of section steel and stacking materials, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high cost and difficult to achieve ideal results, and achieve the effect of light structure, reduced labor intensity, and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

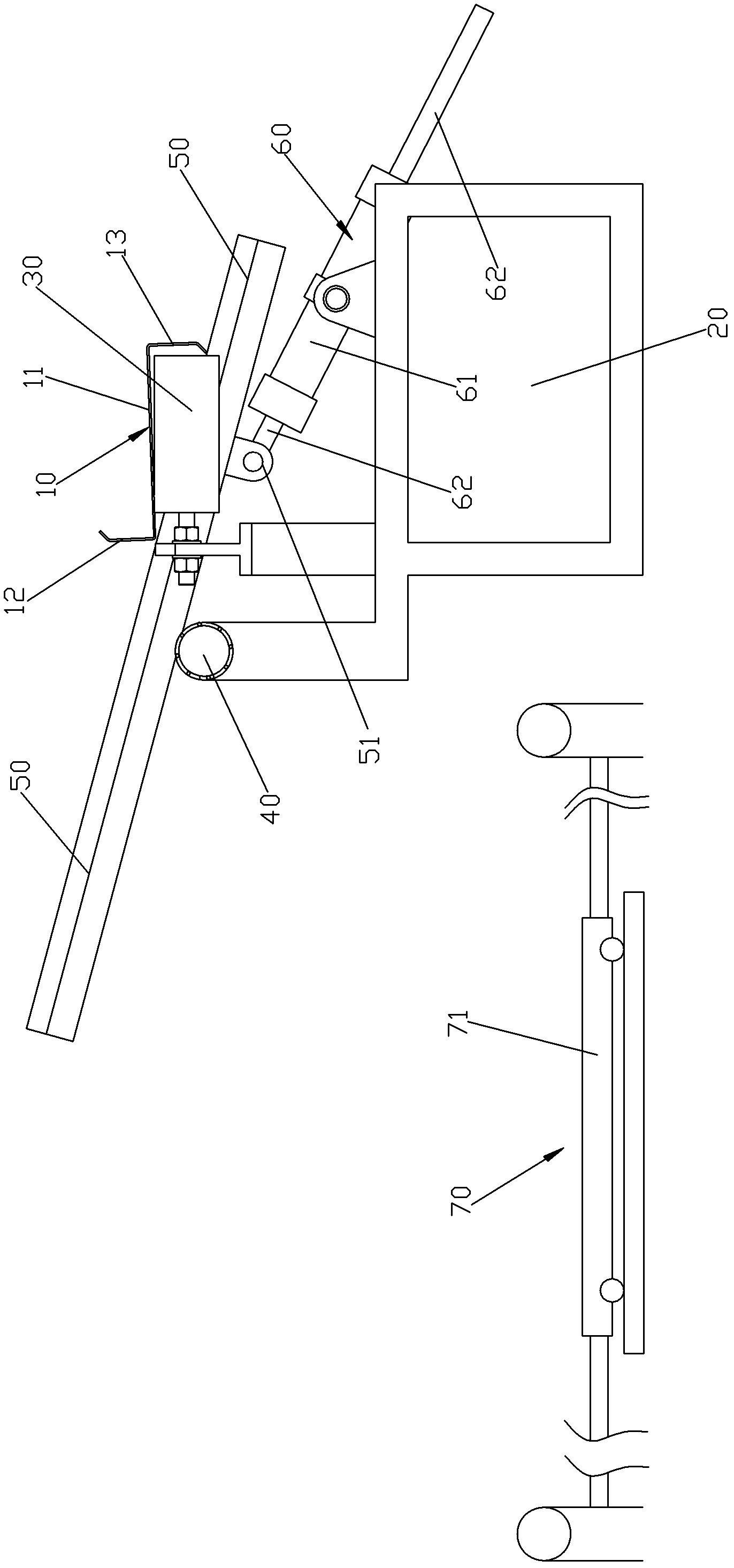

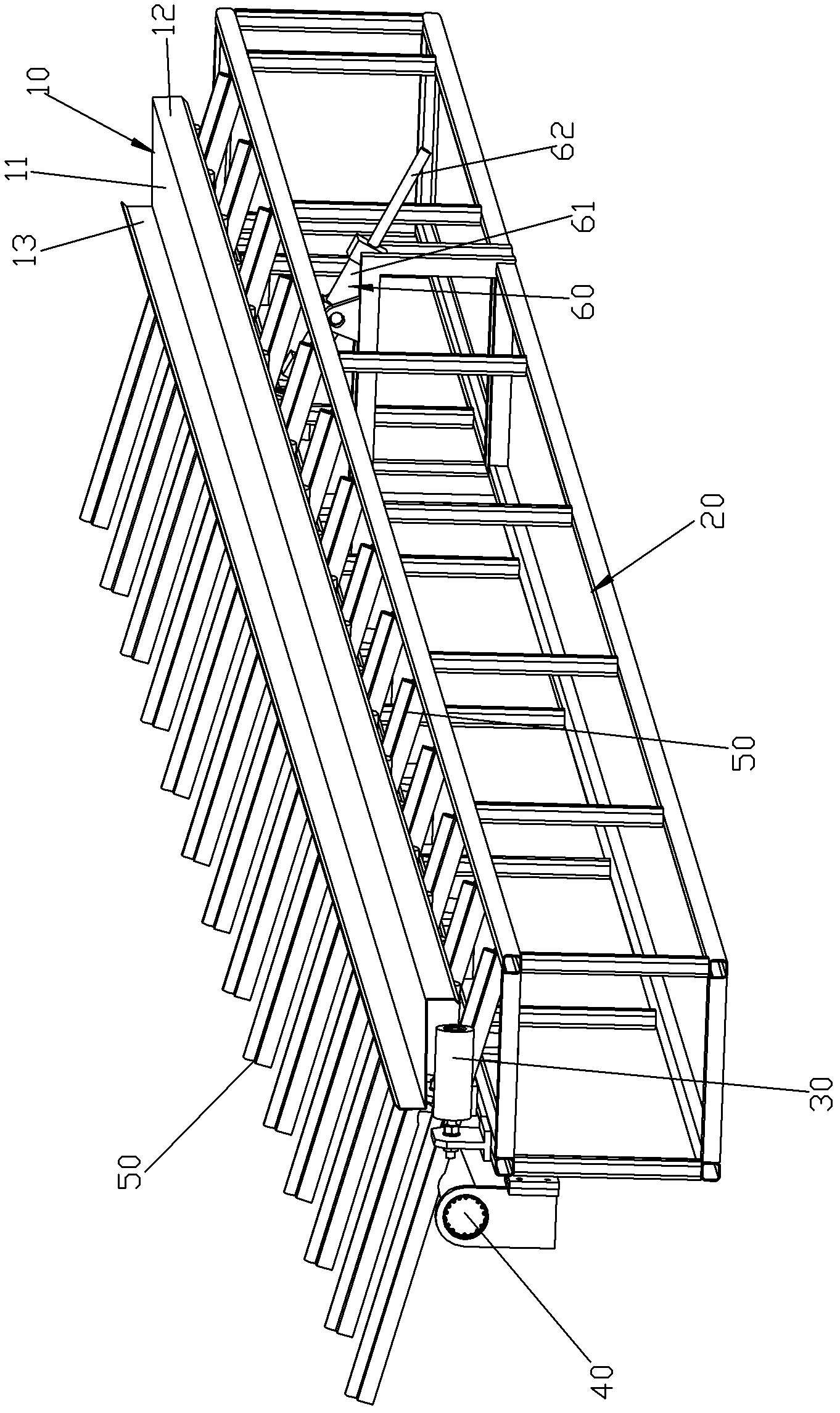

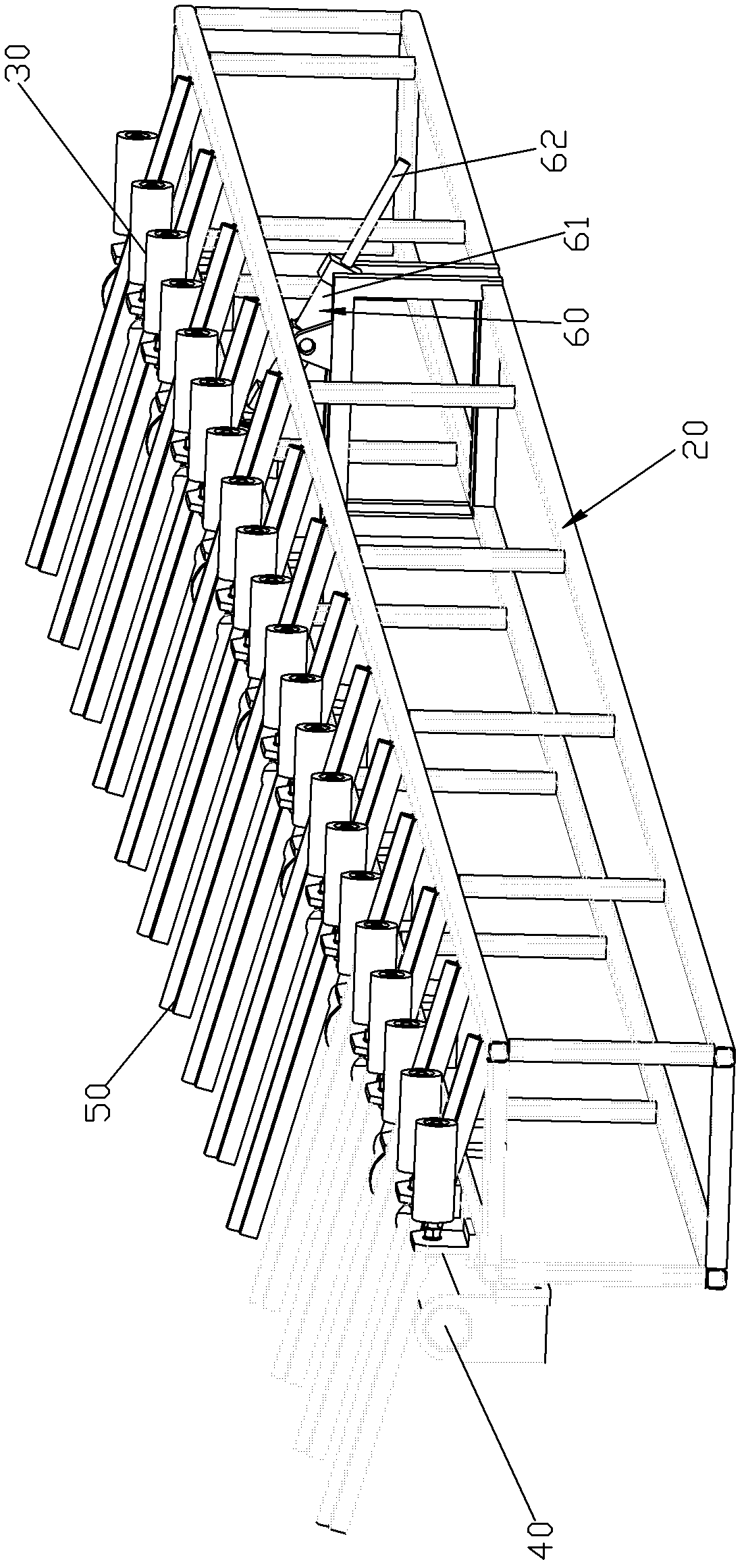

[0036] Please check Figure 1 to Figure 7 , Z-shaped steel stacker, which is used to stack the sheared Z-shaped steel together. The section of the Z-shaped steel 10 has a middle plate 11 and a left side plate 12 and a right side plate 13 respectively connected to the left and right sides of the middle plate 11 .

[0037] The stacker includes a base 20 , several horizontal supporting shafts 30 , a turning mechanism and a stacking mechanism 70 .

[0038] The base 20 includes a rectangular frame, a plurality of pillars arranged at intervals protrude from the upper left pole of the rectangular frame, and a connecting seat protrudes from the left upper pole of the rectangular frame. The several horizontal supporting shafts 30 are mounted on the base 20 and spaced in parallel along the direction X. In this embodiment, the plurality of supporting shafts 30 includes a fixed shaft fixed to the base and a support sleeve rotatably fitted outside the fixed shaft. In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com