Copper heat tube with high-tooth fins and production technology of copper heat tube

A high-tooth fin copper and production process technology, applied in the field of heat pipes, can solve the problems of high manufacturing cost and low heat dissipation efficiency, and achieve the effects of good shock resistance, high heat exchange efficiency and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

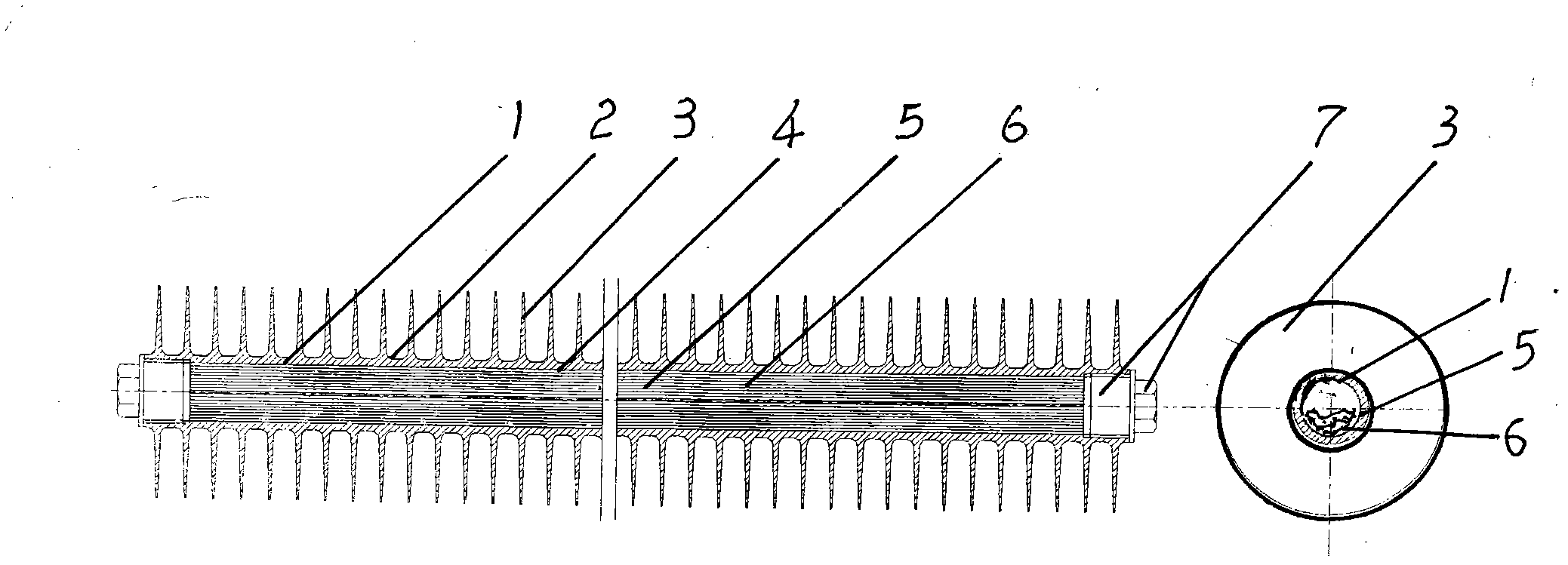

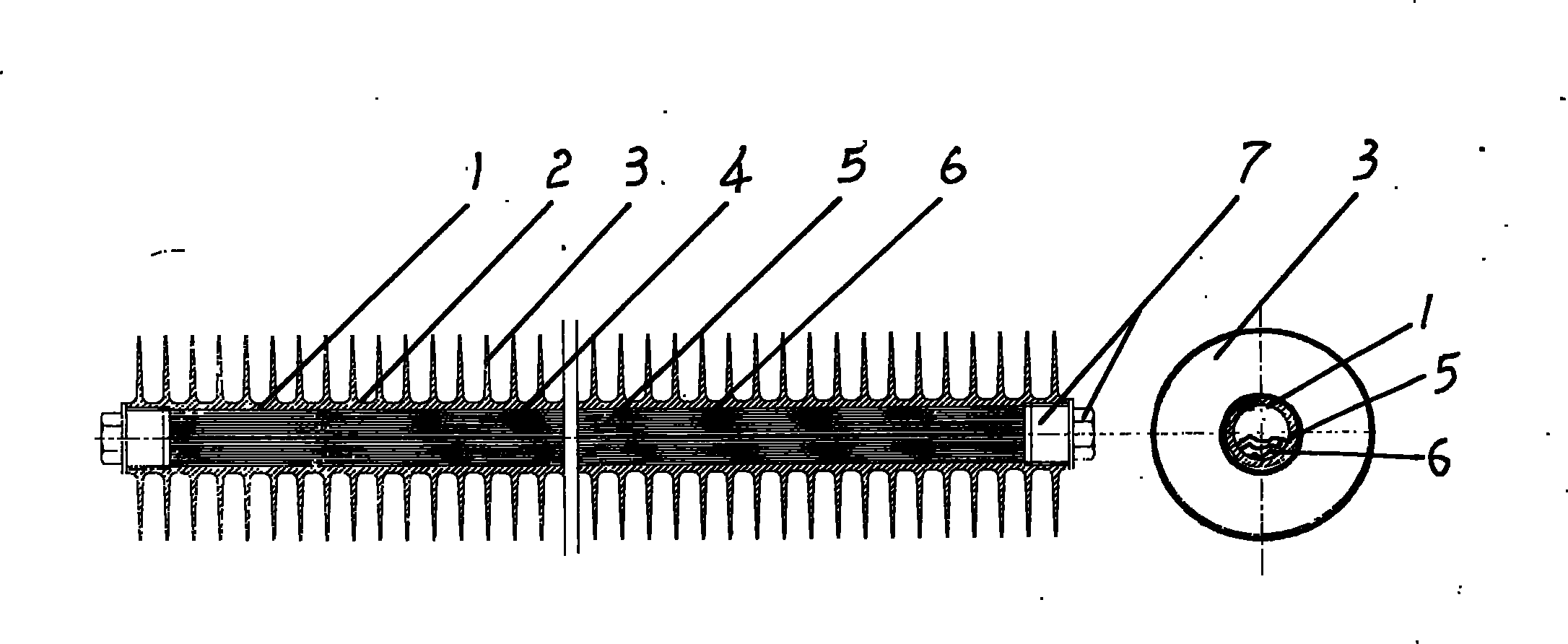

[0021] As shown in the figure, the product of the present invention is mainly composed of copper and copper alloy seamless mother pipe 1, and the outer periphery 2 of the seamless mother pipe 1 is provided with high-toothed fins 3 spirally wound around the pipe body, and the high-toothed fins The sheet 3 and the seamless mother pipe 1 have an integrated structure, and the tube wall 4 of the high-tooth fin seamless mother pipe 1 has multiple and regular raised thread grooves 5 on the circumference, and the high-tooth fin seamless mother pipe 1 Both ends of the tube 1 are sealed with nuts 7 , the high-tooth fin seamless mother tube 1 is kept in a vacuum state, and liquid (distilled water) 6 is injected into the tube.

[0022] The technological process of the present invention adopts a molding process of high-toothed fins and internal threads at the same time.

[0023] The invention is applicable to the fields of electric power, energy, chemical industry, transportation and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com