Combined structure of rotary table and base for small-size five-shaft machining device

A processing device and combined structure technology, applied in the direction of feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult base casting and insufficient stability of turntable precision, etc., and achieve beautiful and harmonious appearance, light weight, The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

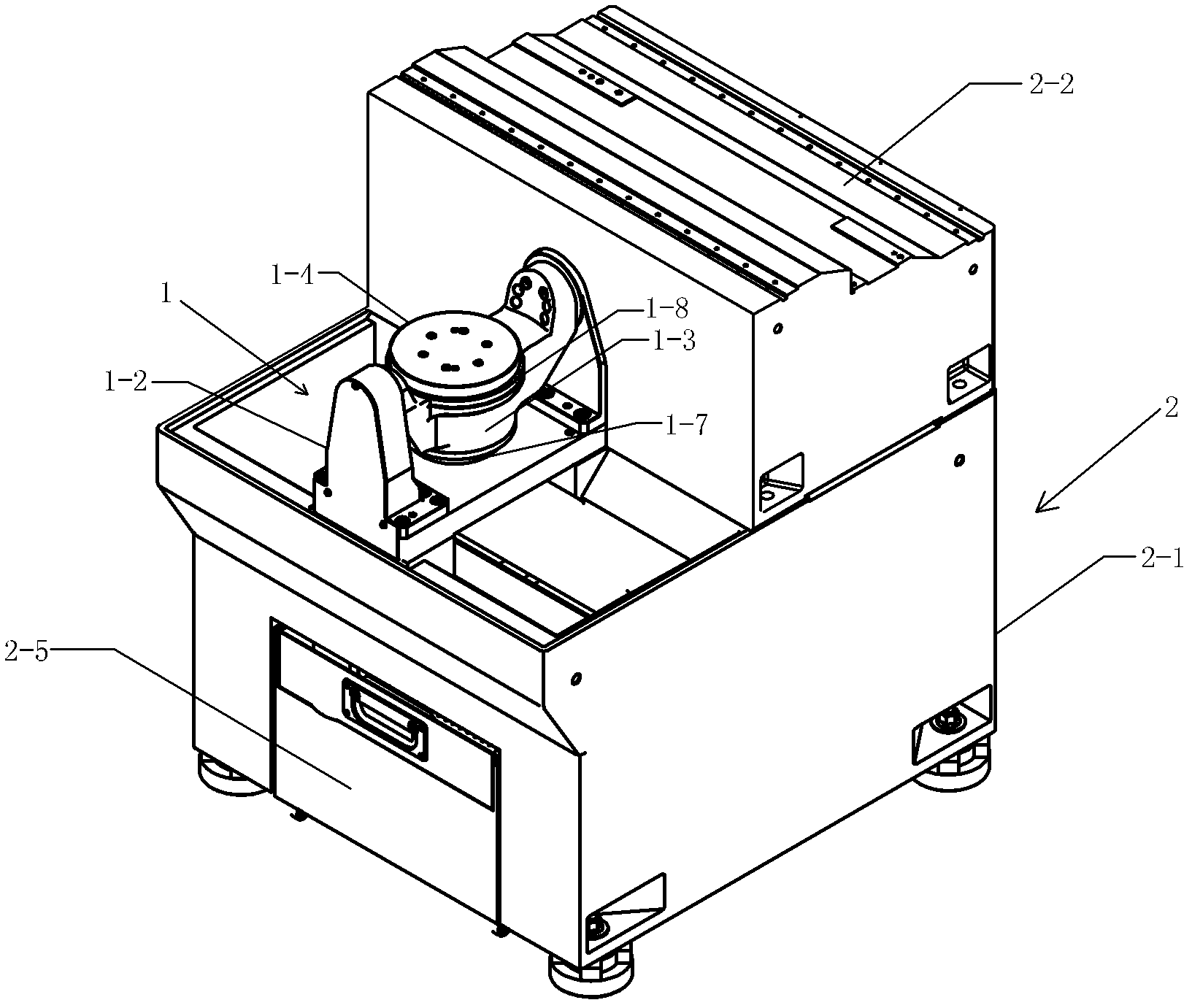

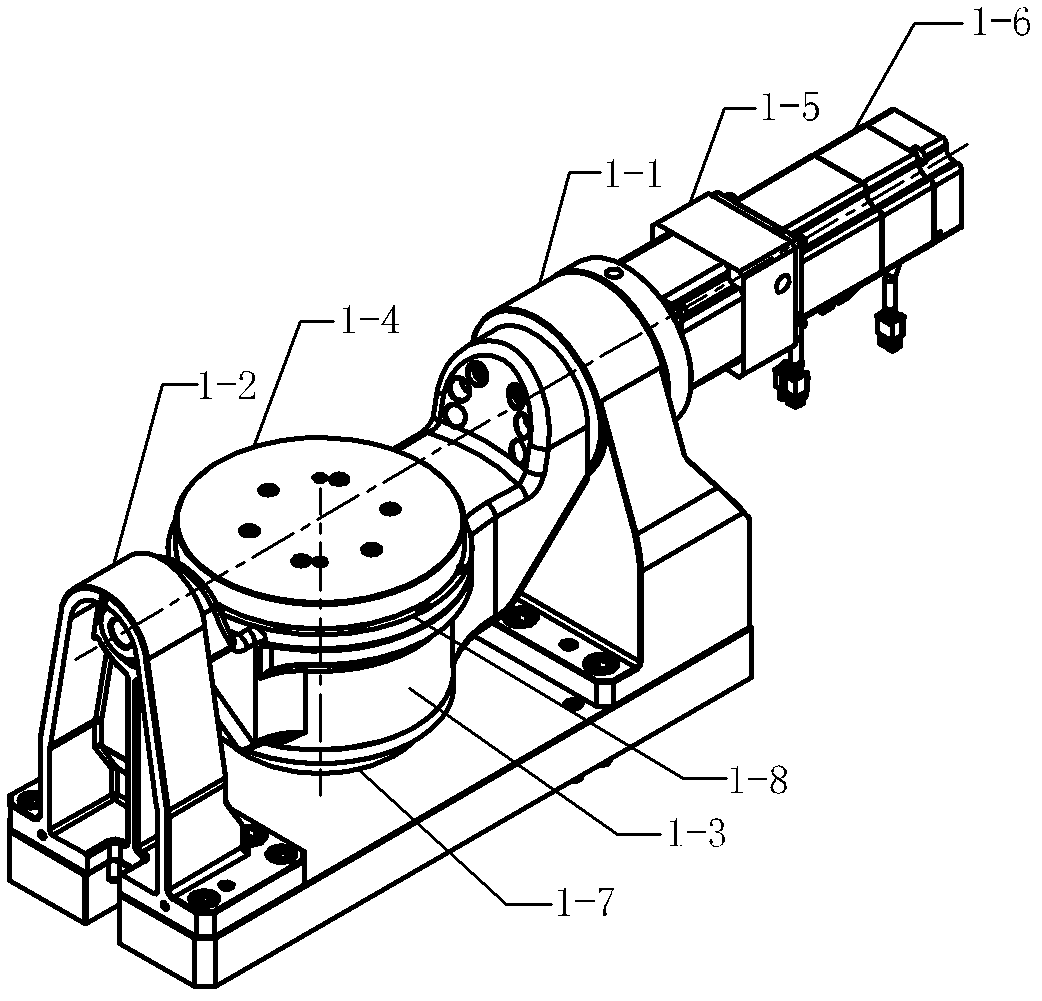

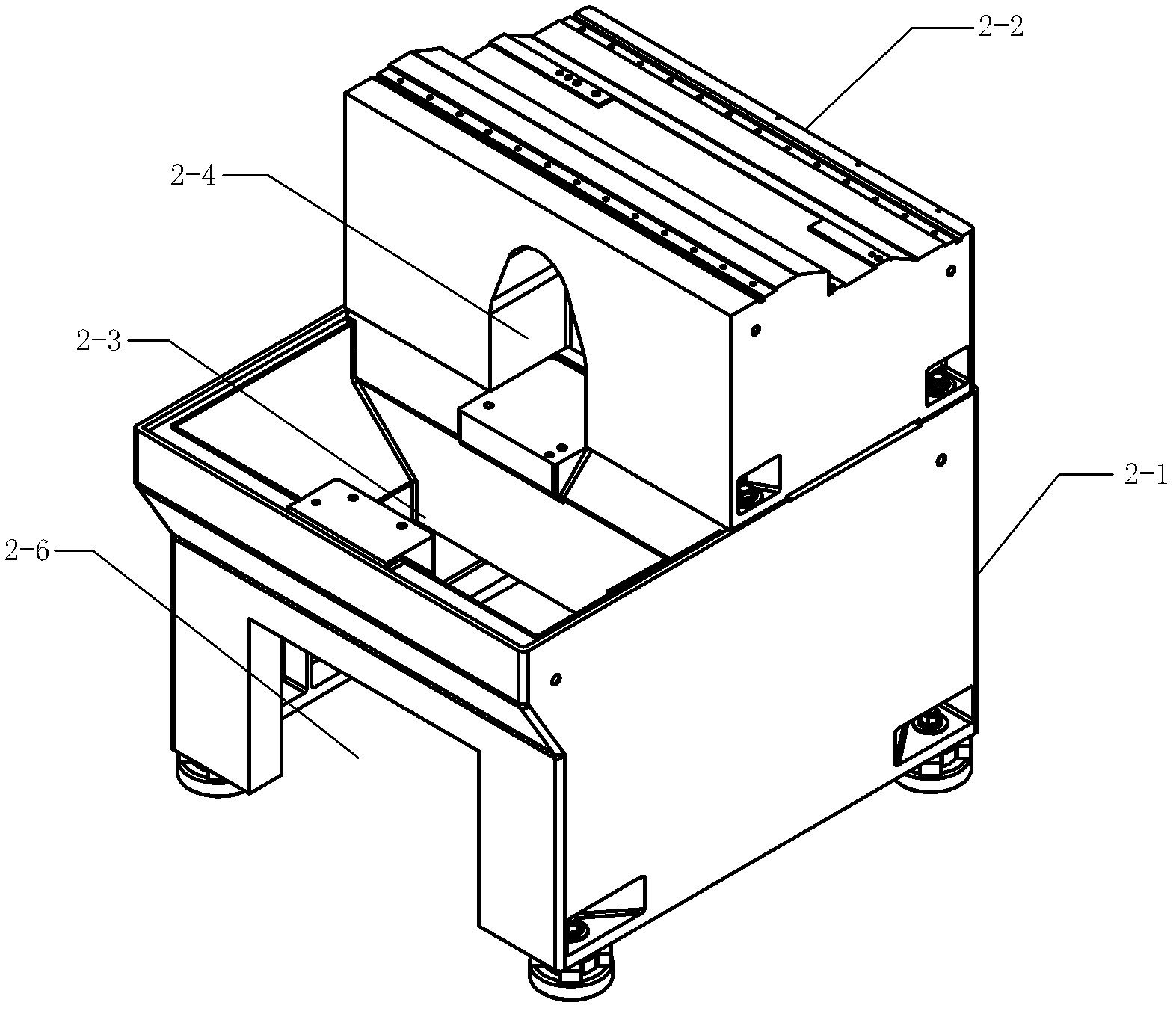

[0024] figure 1 , figure 2 and image 3 Constitute the specific embodiment 1 of the present invention.

[0025] refer to figure 1 , figure 2 and image 3 , the present embodiment includes a turntable part 1 and a base part 2, the base part 2 has an L-shaped structure, forming an X-axis base 2-2 and a hollow machine tool base 2-1; the turntable part 1 is arranged on the base part 2 , The two are fixed connection structures; the turntable part 1 includes the B-axis seat 1-1, the B-axis support seat 1-2, the B-axis lifting lug 1-3 and the C-axis turntable mechanism 1-4, and the B-axis seat 1-1 and the B-axis support base 1-2 are arranged on the machine tool base 2-1, and the two ends of the B-axis lifting lug 1-3 are respectively connected with the upper part of the B-axis base 1-1 and the B-axis support base 1-2, and the C-axis The turntable mechanism 1-4 is set in the middle of the B-axis lifting lug 1-3; at the connection between the B-axis lifting lug 1-3 and the B-ax...

specific Embodiment 2

[0032] The feature of this embodiment is: the turntable part 1 is arranged on the base part 2, and the two are integrally formed. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com