Method for planning trajectories of industrial robot based on NC (numerical control) codes

An industrial robot and trajectory planning technology, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as complicated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

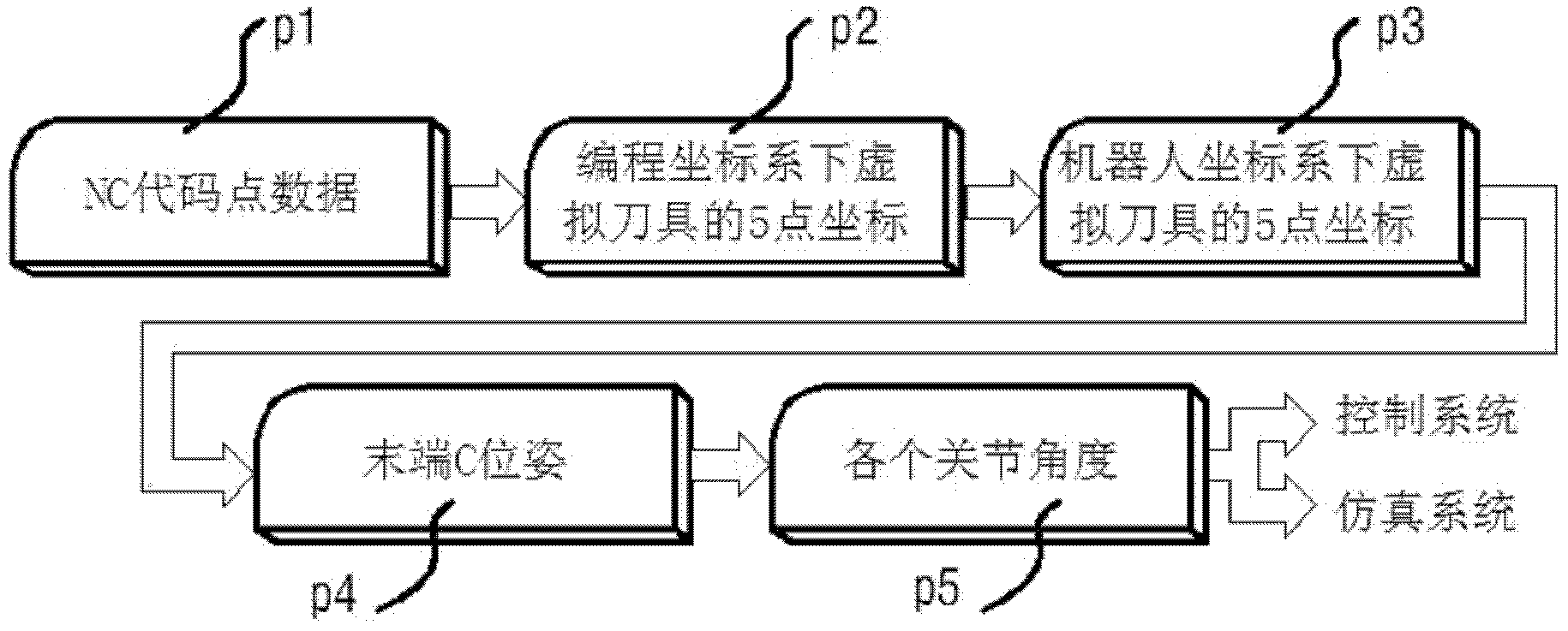

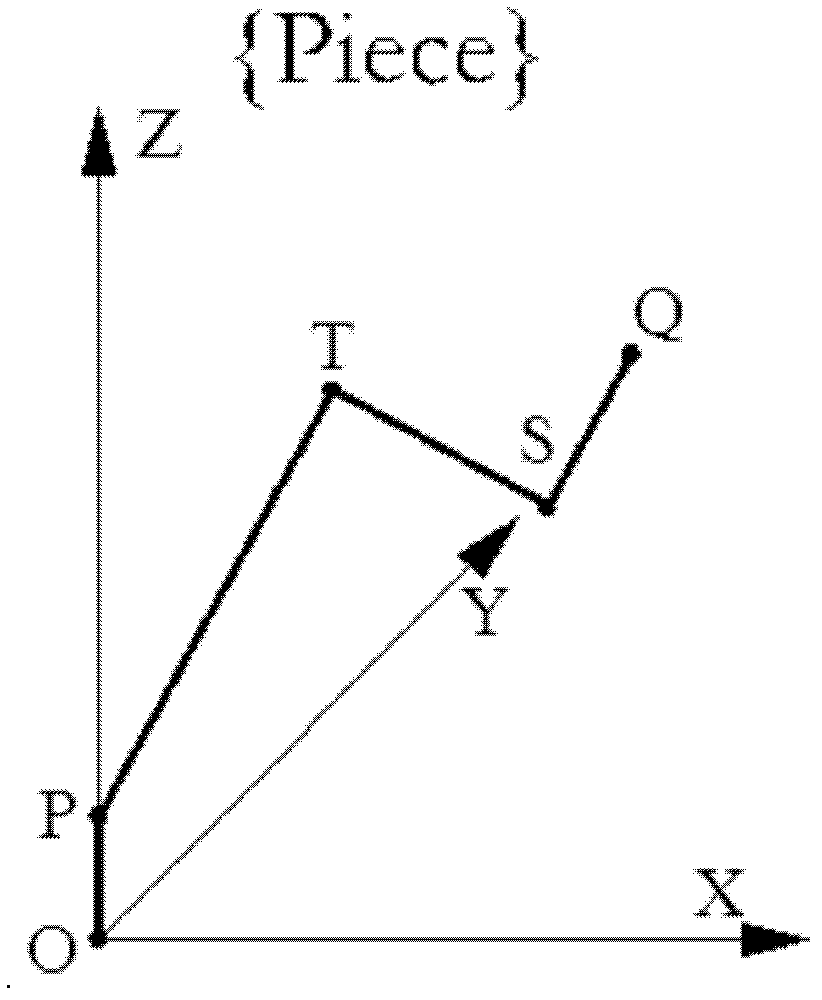

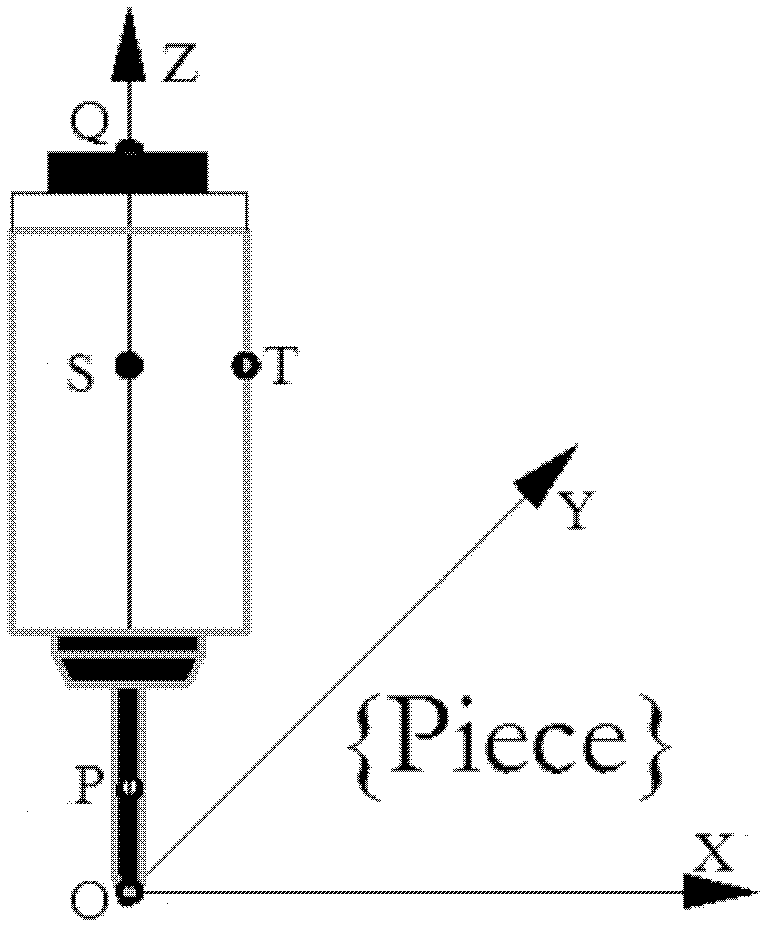

[0075] According to the fact that the end tool of the industrial robot is a rigid body fixed to the sixth degree of freedom of the robot, the general NC code is used as the working language of the industrial robot, and the end tool of the industrial robot is used as a virtual tool in the programming coordinate system. Five points are used to describe the basic characteristics of the virtual tool, set five points O, P, Q, S, T, point O is set at the origin of the programming coordinate system, point P is set on the Z axis of the programming coordinate system, and the other three Points Q, S, and T are set according to the specific characteristics of the end tool. Set the Q point so that the Q point coincides with the wrist center C point after the tool is installed, and the straight line QS and straight line ST are perpendicular to each other, such as image 3 ;Transform the data of each NC code, so that the five points of the virtual tool in the programming coordinate system ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com