Tempered glass decorative plate printed with three-dimensional patterns and printing process thereof

A tempered glass, three-dimensional technology, applied in the printing process, the printing of special varieties of printed matter, decorative art, etc., can solve the problems of dizziness and partial treatment, and achieve simple process, flexible and vivid pattern visual effect, and shrink tortoise The effect of grain area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

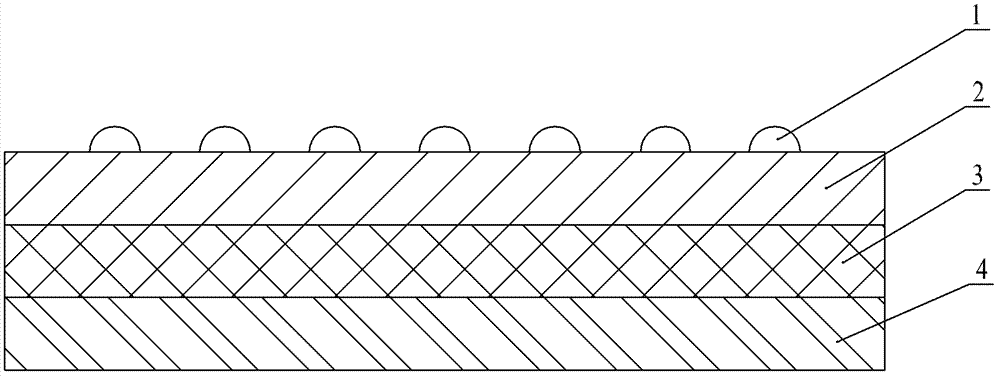

[0019] Example 1: Production of on-hook panels for air conditioners

[0020] (1) Cut the ordinary glass according to the required size, and perform 0.5mm, 45-degree bevel on the side for safety chamfering, as the substrate 2; send the finished substrate 2 into the semi-automatic screen printing machine, According to the shape of the pattern to be formed, a pattern area is planned on the front of the substrate 2, and a 300-mesh screen is used to print transparent bumps 1 with a mixed high-temperature resistant UV varnish in the pattern area, and then cured by a UV light curing machine;

[0021] (2) Send the substrate 2 with printed transparent bumps 1 into a tempering furnace, and heat it for 6 minutes at a temperature of 700°C for tempering;

[0022] (3) Place the tempered substrate 2 on the working table of the screen printing machine, start printing, transmit power through the transmission mechanism, let the squeegee squeeze the ink and the screen printing plate in motion, a...

Embodiment 2

[0024] Example 2: Production of air-conditioning cabinet panels

[0025] (1) Cut the ordinary glass according to the required size, and perform 0.5mm, 45-degree bevel on the side for safety chamfering, as the substrate 2; send the finished substrate 2 into the semi-automatic screen printing machine, According to the shape of the pattern to be formed, a pattern area is planned on the front of the substrate 2, and a 300-mesh screen is used to print transparent bumps 1 with a mixed high-temperature resistant UV varnish in the pattern area, and then cured by a UV light curing machine;

[0026] (2) Send the substrate 2 with printed transparent bumps 1 into a tempering furnace, and heat it for 5 minutes at a temperature of 700°C for tempering;

[0027] (3) Place the tempered substrate 2 on the working table of the screen printing machine, start printing, transmit power through the transmission mechanism, let the squeegee squeeze the ink and the screen printing plate in motion, and m...

Embodiment 3

[0029] Example 3: Production of refrigerator panels

[0030] (1) Cut the ordinary glass according to the required size, and perform 0.5mm, 45-degree bevel on the side for safety chamfering, as the substrate 2; send the finished substrate 2 into the semi-automatic screen printing machine, According to the shape of the pattern to be formed, a pattern area is planned on the front of the substrate 2, and a 300-mesh screen is used to print transparent bumps 1 with a mixed high-temperature resistant UV varnish in the pattern area, and then cured by a UV light curing machine;

[0031] (2) Send the substrate 2 with printed transparent bumps 1 into a tempering furnace, and heat it for 5 minutes at a temperature of 750°C for tempering;

[0032] (3) Place the tempered substrate 2 on the working table of the screen printing machine, start printing, transmit power through the transmission mechanism, let the squeegee squeeze the ink and the screen printing plate in motion, and make the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com