Speed-reducing type wheel electric drive system of electric vehicle

An electric drive system, electric vehicle technology, applied in motion deposition, power plant, vehicle components, etc., can solve the problems of limited vibration reduction, narrow space, and high system cost, reduce unsprung mass, and reduce negative mass effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

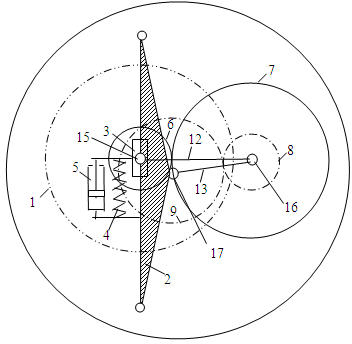

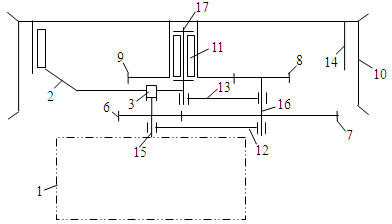

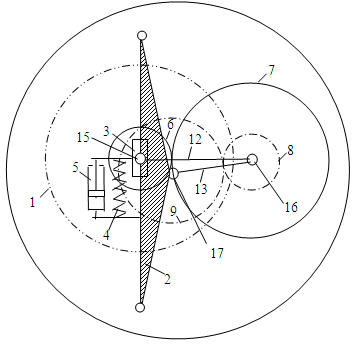

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 As shown, the first-stage reduction gear pair consists of a first-stage driving gear 6 fixedly connected to the output shaft of the motor shaft 15 and a first-stage driven gear 7 fixedly connected to the intermediate shaft 16; The secondary driving gear 8 of 16 and the secondary driven gear 9 fixedly connected to the hub 10 are formed; the hub 10 is fixedly connected with the secondary driven gear 9 coaxially, and is supported on the suspension steering knuckle 2 through the hub bearing 11 on the wheel support shaft 17, and rotate around the axis of the wheel support shaft 17.

[0014] The two ends of the primary reduction gear pair center connecting rod 12 are respectively hinged with the motor shaft 15 and the intermediate shaft 16 through a rotary pair, and the axis of the rotary pair coincides with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com