Vehicle-mounted comprehensive test system used for condition based maintenance for electrical equipment

A state-of-the-art maintenance and power equipment technology, which is applied to vehicles used for freight, measuring electricity, motor vehicles, etc., can solve problems such as difficulty in ensuring timely arrival at the scene, limited coverage of tested equipment, and anti-interference of test safety data. , to achieve the effect of reducing the number of test wiring, avoiding the replacement of test equipment, and improving the quality of test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

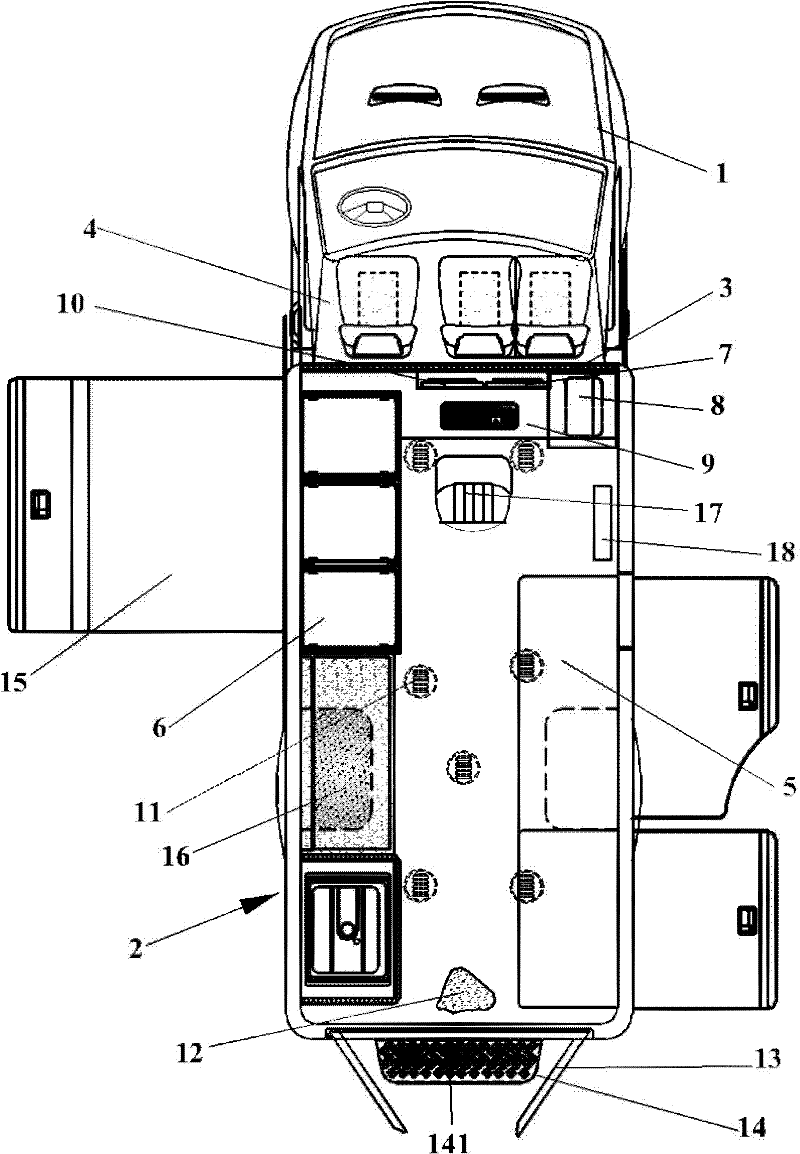

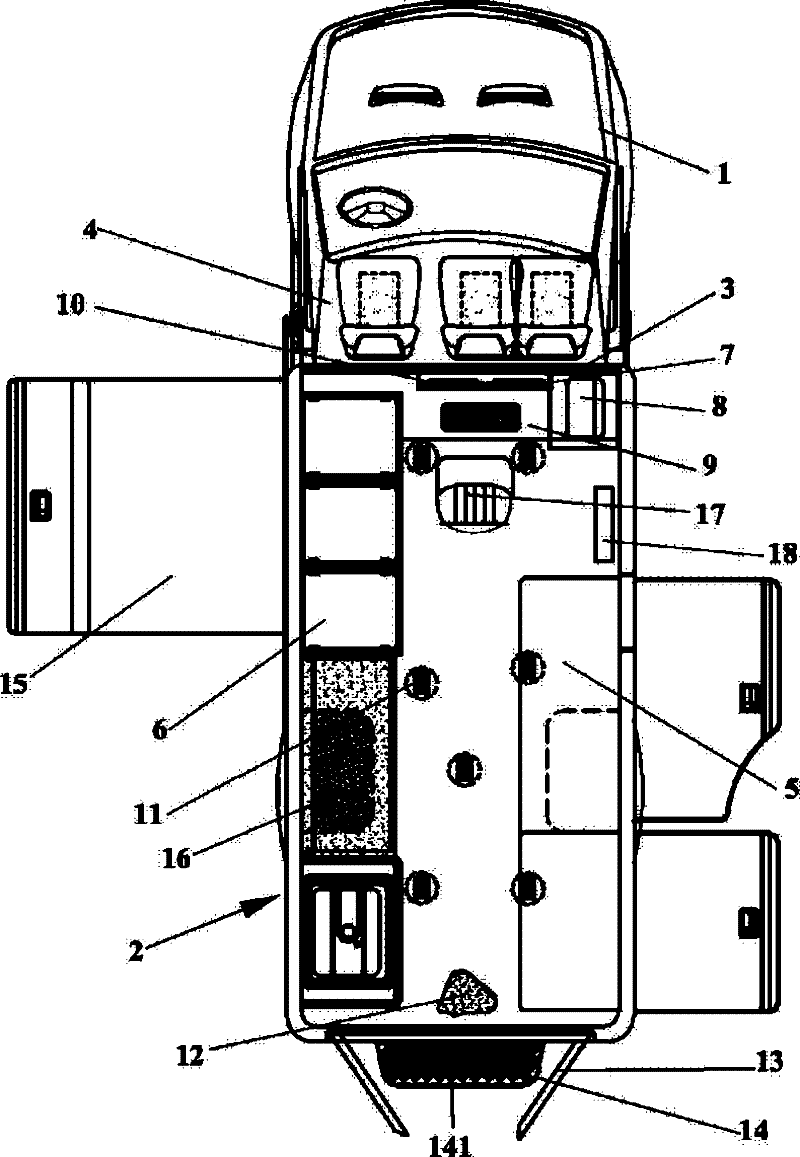

[0025] see figure 1 , a vehicle-mounted comprehensive test system for condition maintenance of electrical equipment, including a vehicle body, the vehicle body includes a headstock 1 and a compartment 2, a partition plate 3 is provided between the headstock 1 and the compartment 2; the headstock 1 includes a cab 4; The compartment 2 is provided with a test bench 5 for testing electrical equipment, a cabinet 6 for placing test instruments, a console 9 for placing a control computer, a display 7 and a printer 8 for testing, and a control panel for monitoring the test system. The monitoring unit, the lighting unit used to provide lighting for the test system, the walkie-talkie used to enable the testers in the vehicle to communicate with the staff outside the vehicle, and the test equipment, control computer, monitoring unit, and display7 , the printer 8 and the lighting unit provide a safe power supply for power supply; the test instrument and the control computer are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com