Material breakage emergency device of belt material processing production line

An emergency device and processing device technology, which is applied in thin material handling, transportation and packaging, winding strips, etc., can solve problems affecting efficiency, affecting production efficiency, and scrapping online products in batches, so as to improve production efficiency and reduce product The effect of scrap volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

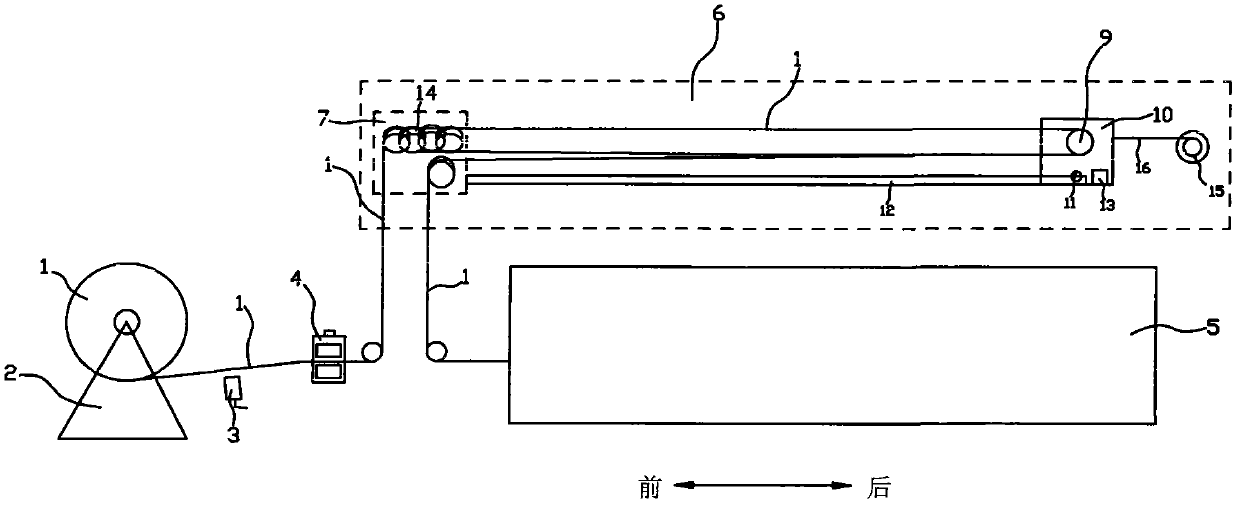

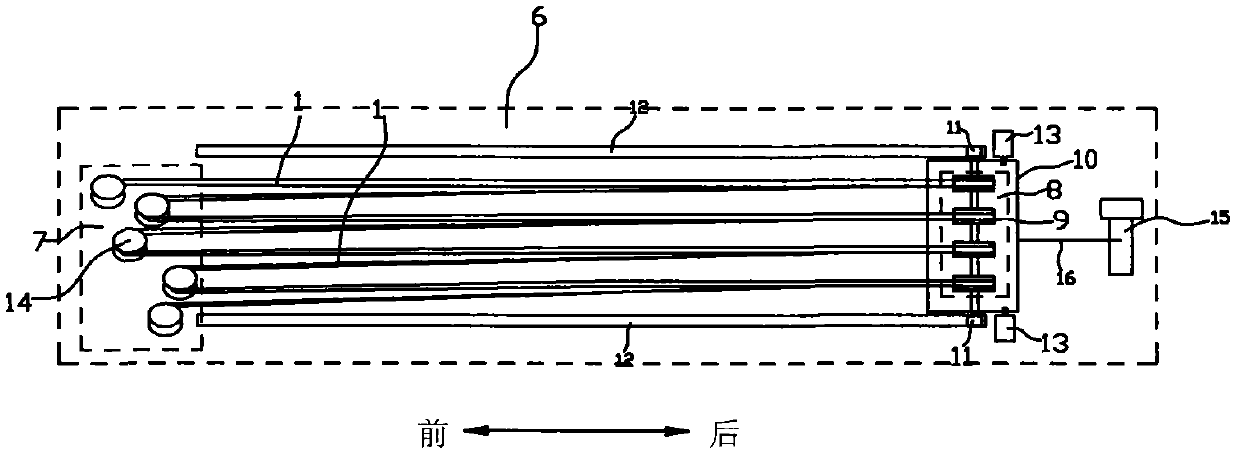

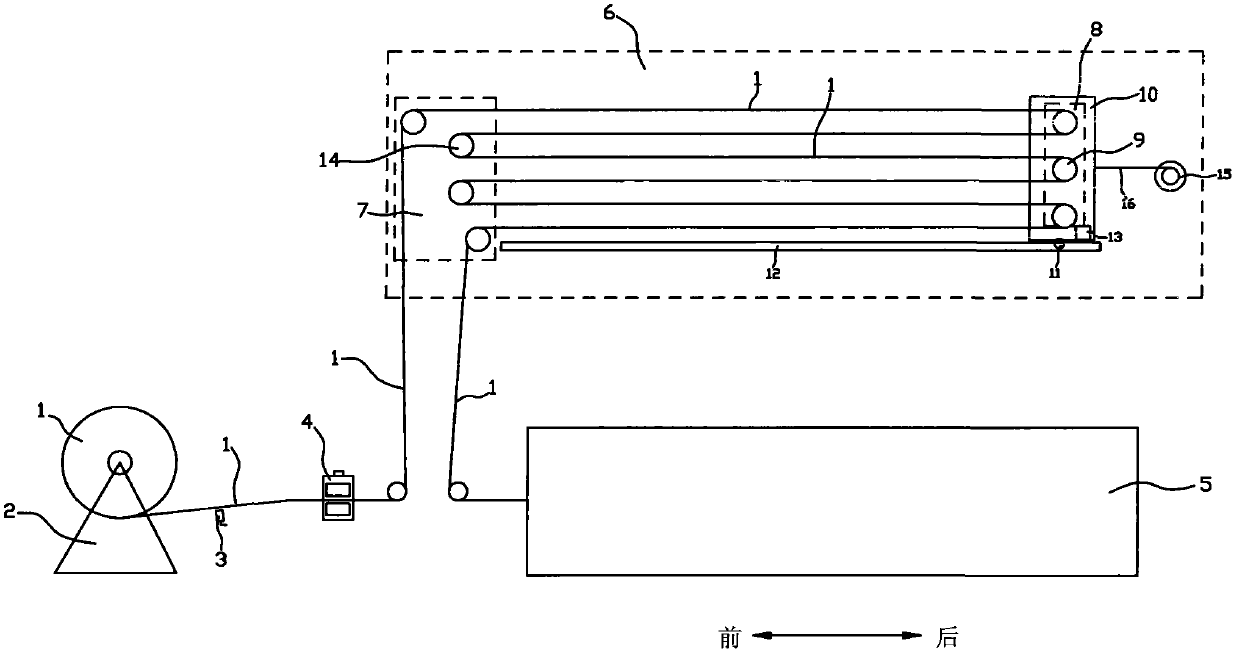

[0017] like Figures 1 to 4 As shown, the coiled strip material 1 is placed on the material rack 2, and the subsequent processing device 5 pulls the strip material 1 from the material rack 2 to be transported to the processing device 5 continuously.

[0018] After the strip material 1 is withdrawn from the material rack 2, a photoelectric probe 3 for detecting the presence or absence of the strip material 1 and a hold-down device 4 for pressing the strip material 1 when cutting the material are arranged in sequence at the place where it passes. And before the belt material 1 enters the follow-up processing device 5, it first enters an additional storage device 6, and the belt material 1 circles around the front wheel set 7 and the rear wheel set 8 of the material storage device 6 repeatedly back and forth, wherein the front wheel Group 7 is fixedly set, and rear wheel set 8 is set movable; during normal material feeding, the pressing device 4 does not work, and when the photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com