Cross-shaped hoisting device for weight on table board of horizontal type test bed

A lifting device and test bench technology, which is applied to cranes, transportation and packaging, trolley cranes, etc., can solve the problems of high environmental requirements, high cost, and the need for power transformation when purchasing bridge cranes, so as to reduce manufacturing difficulty, The effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

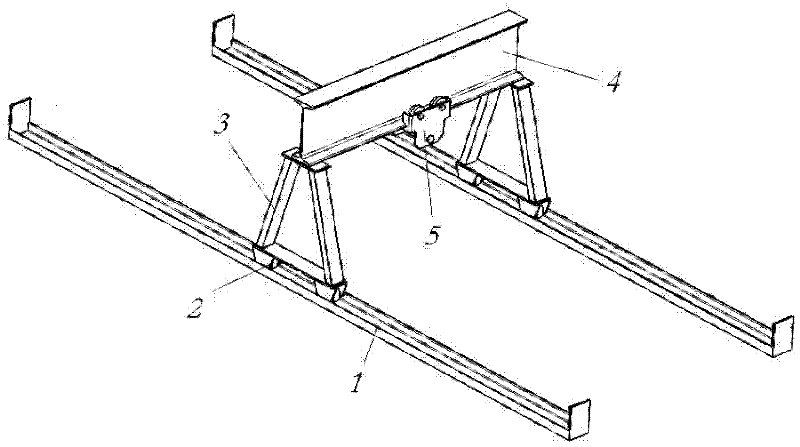

[0016] figure 1 It is a specific embodiment of the present invention. The longitudinal running device is provided with two running rails 1 with safety stops along the beam length direction, and the two running rails are equipped with eight-shaped brackets 3 with running wheels 2. The ends are fixed, the transverse running rail 4 spans and is perpendicular to the longitudinal running device, and the horizontal running device 5 is arranged on the transverse running rail 4, and a hand hoist crane is installed on the running device.

[0017] The running wheel 2 is installed on the splayed support 3, and the horizontal running rail 4 is arranged above the bracket, and the horizontal running device 5 and the hand block are placed on the running rail. After completing these tasks, the whole set of devices is installed in the running rail 1 at the top of the column of the test be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com