Purification method for 69KD outer membrane protein of pertussis bacillus

A technology for outer membrane protein and whooping cough, applied in the field of protein separation and purification, can solve the problems of high cost of materials, many steps, and long time-consuming dialysis steps, and achieve the effect of low cost and high-efficiency inoculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1. the selection of thalline treatment method and the optimization of condition

[0068] 1.1 Acquisition of bacteria:

[0069] Cultivate the CS bacterial strain (CMCC58003, purchased from ATCC (American Type Microorganism Collection Center)) in 10L S-S medium to a cell concentration of 22 billion / ml, centrifuge at 8000rpm for 10 minutes to obtain the cell, and use 0.035mol / L Sodium chloride, 1mmol / L ethylenediaminetetraacetic acid (EDTA), 0.025mol / L Tris-HCl buffer solution of pH 8.8 of 1mmol / L phenylmethylsulfonyl fluoride (PMSF) dissolves bacterium, obtains 0.05g / ml of bacterial suspension, and processed according to the following methods.

[0070] 1.2 Three ways to deal with bacteria:

[0071] A. Concentrated salt solution leaching supernatant: Suspend the bacteria in Tris-HCl buffer solution containing 0.5mol / L NaCl, put in a water bath at 60°C for 1 hour, centrifuge at 8500r / min at 4°C for 10 minutes, and take the supernatant.

[0072] B. Obtain the ...

Embodiment 2

[0086] Embodiment 2. The selection of crude extraction method and the optimization of conditions

[0087] 2.1 Ethanol precipitation crude extraction method:

[0088] Through the above optimized conditions (1mol / LNaCl, incubate at 60°C for 1 hour) to obtain concentrated salt solution extract, pre-cool 2 times the volume of ethanol at -20°C for 30 minutes, then slowly add ethanol to the extract, and stir evenly , -20°C for 30 minutes. 10000r / min, 4°C, centrifuged for 30 minutes, and the precipitate obtained by centrifugation was mixed with 0.035mol / L sodium chloride, 1mmol / L ethylenediaminetetraacetic acid (EDTA), 1mmol / L phenylmethylsulfonyl fluoride (PMSF) 0.025 mol / L Tris-HCl buffer solution of pH 8.8 was dissolved, and dialyzed against this buffer solution overnight.

[0089] 2.2 Ammonium sulfate precipitation:

[0090] Add ammonium sulfate to the concentrated salt solution extract obtained by the above method (1mol / LNaCl, incubate at 60°C for 1 hour) to make the concentr...

Embodiment 3

[0095] Example 3: Determination of the column chromatography purification method of fine extraction and optimization of conditions

[0096] 3.1 Affinity gum blue (AGB) column chromatography:

[0097] Under the above-mentioned conditions, leaching with concentrated salt and passing through 20% by weight / volume and 33% by weight / volume of ammonium sulfate fractional precipitation obtains the precipitate and dissolves, and the obtained protein crude extract is in 20mmol / L Tris-HCl (pH7.4 ) buffer, stirred at 4°C, and equilibrated. Wash the chromatographic column with an aqueous solution of potassium dihydrogen phosphate with a concentration of 0.5 mmol / L at pH 7.5 to remove impurity proteins, and use pH 8.0 containing 4 mol / L urea, 0.15 mol / L sodium chloride, 1 mmol / LEDTA, 1 mmol / L L PMSF and 10mmol / L Tris-HCl buffer to elute the target protein.

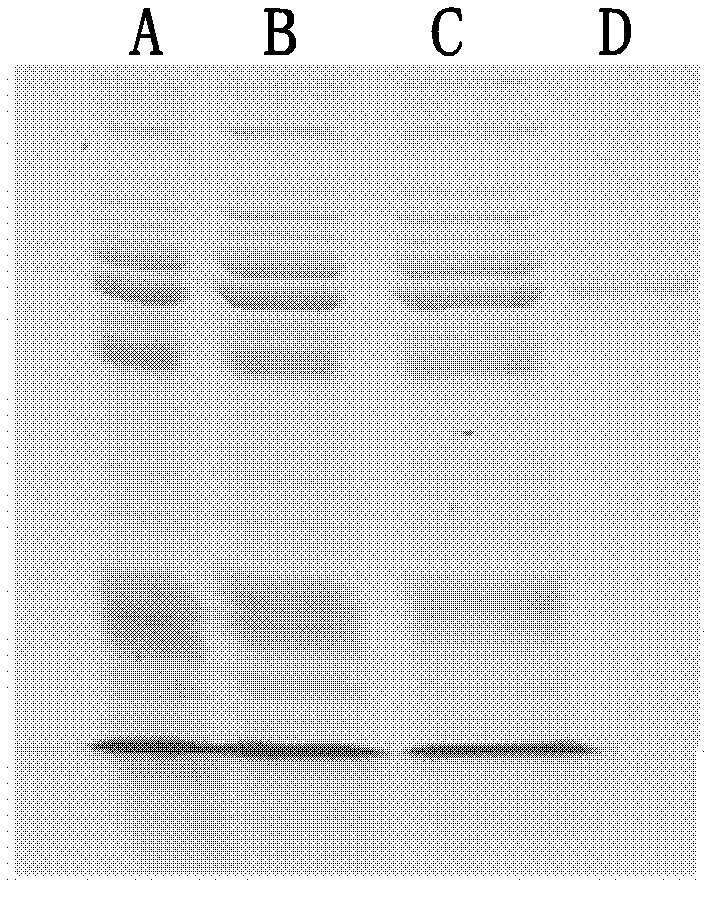

[0098] The results after electrophoresis of the samples collected after the AGB column are as follows: Image 6 As shown, lanes A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com