A kind of preparation method of mushroom and black fungus mold strain

A production method and technology of black fungus, applied in botany equipment and methods, mushroom cultivation, horticulture, etc., can solve the problems of affecting contact area, affecting survival rate, hidden danger of secondary infection, etc., and achieve economical and reasonable size, unique structure, The effect of low pollution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A kind of preparation method of mushroom black fungus plastic mold strain comprises the following steps:

[0019] S1, making the bacteria mold

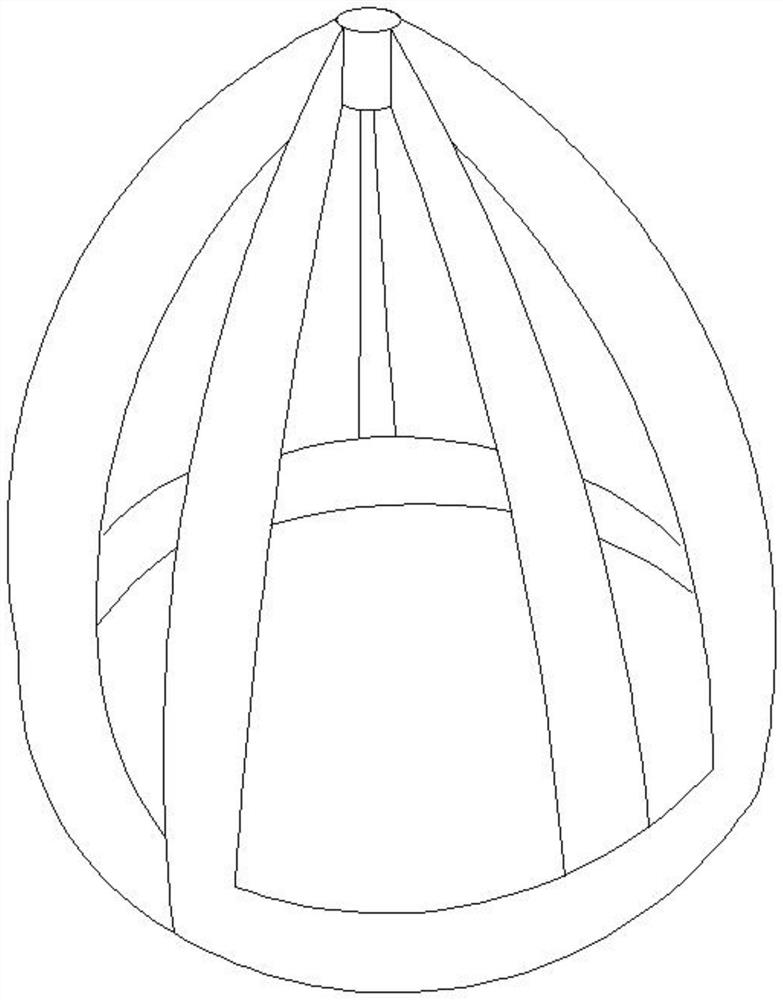

[0020] like figure 1 As shown, the strain mold adopts a nearly conical structure, including a circular bottom edge and a cylindrical head, and 3 to 9 arc-shaped, oblong, strip-shaped tendons are evenly arranged on the bottom edge, according to A certain radian converges on the cylindrical head to form a nearly conical hollow mold, which is obtained by making abrasive tools according to the size and injection molding; the total length of the mold with the nearly conical structure is set to 2.5-5cm, wherein : The inner diameter of the ring-shaped bottom of the main body is 1-3cm, the width is 0.1-0.5cm, and the wall thickness is 0.1-0.5cm; the arc-shaped and oblong strip-shaped rib column is 0.1-0.5cm wide, 0.1-0.4cm thick, cylindrical The head is 0.3-1 cm long, 0.1-0.5 cm in diameter, and the top is arc-shaped;

[0021] S2. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com