Composition for warm-mix asphalt pavements

A technology of warm-mix asphalt and composition, which is applied in building construction, solid waste management, building insulation materials, etc., and can solve the problems that it is difficult to simultaneously satisfy high-temperature plastic deformation resistance and low-temperature crack resistance, and difficult low-viscosity characteristics of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

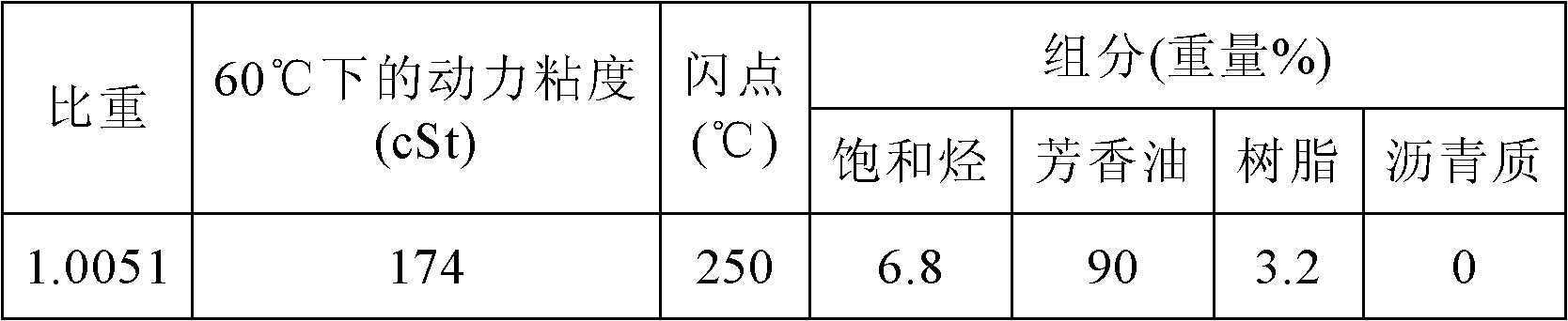

Method used

Image

Examples

Embodiment 1

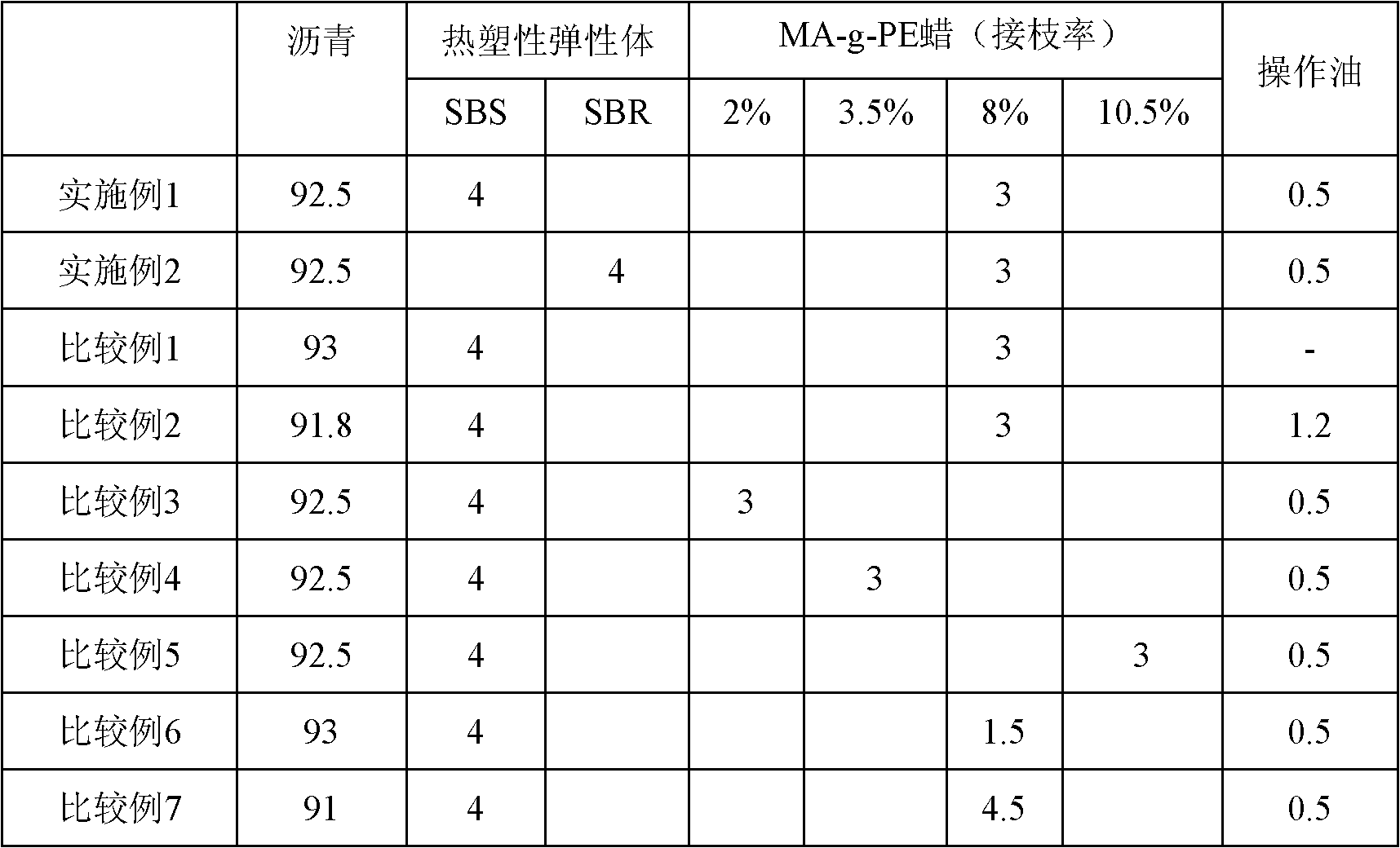

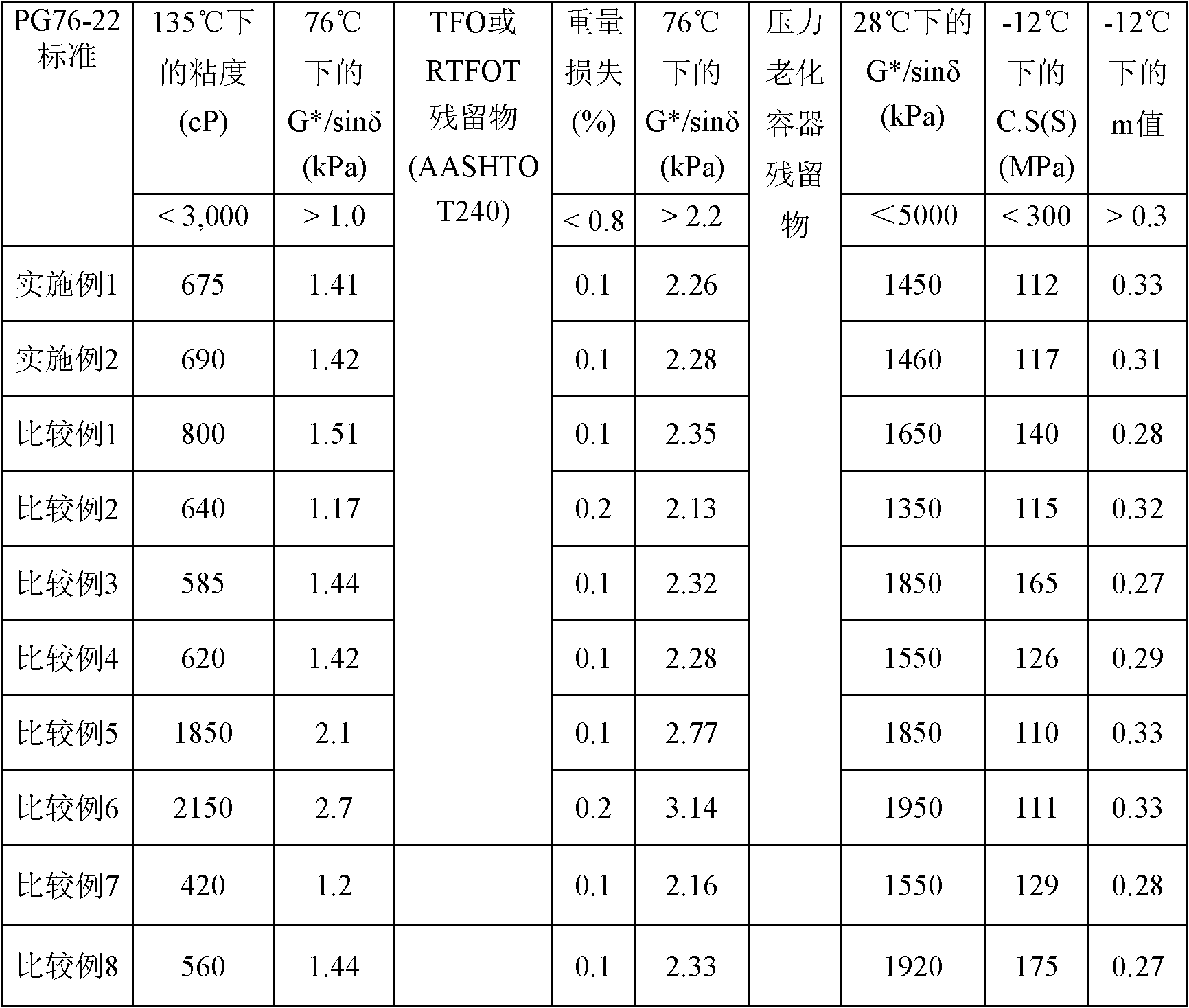

[0073]Bituminous compositions were prepared based on Table 2. 92.5 parts by weight of asphalt was heated to 163°C, and then 0.5 parts by weight of process oil and 3 parts by weight of MA-g-PE wax with a molecular weight of 4200 (grafting ratio: 8%) were mixed with the heated asphalt to form the first Then, while maintaining a constant temperature, the first mixture was stirred at a speed of 2,000 rpm for 0.2 h to completely melt. After that, 4 parts by weight of styrene-butadiene-styrene block copolymer (SBS) having a styrene content of 30.5% was added to the molten first mixture to form a second mixture, and then the second mixture was heated While reaching 175° C., the second mixture was evenly stirred at a rotation speed of 2,200 rpm for 2 hours to completely melt, thereby preparing an asphalt composition.

Embodiment 2 and comparative example 1 to 7

[0075] An asphalt composition was prepared in the same manner as in Example 1 except that the component contents were changed as shown in Table 2 below.

[0076] Table 2

[0077] Unit: parts by weight

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com