Method and system for removing and supplying antioxidant from/to transformer insulating oil impurities

A transformer insulating oil and antioxidant technology, which is applied in the petroleum industry, lubricating compositions, material inspection products, etc., can solve the problems of inability to monitor transformer insulating oil, economic loss, environmental pollution, transformer equipment damage, etc. The effect of reliability, reducing environmental pollution and increasing service life

Active Publication Date: 2012-07-18

BEIJING ANSAIBO TECH

View PDF8 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Although the technical means described in the above-mentioned U.S. patent are very effective for the monitoring of engine lubricating oil, the above-mentioned technical means cannot be directly used for monitoring the transformer insulating oil, which is due to the following reasons: first, the transformer equipment itself and the engine still have There is a certain difference, the working temperature of the oil in these two devices is different, and the change of the temperature gradient experienced by the oil is also different; secondly, the materials and materials that the oil in these two devices come into contact with are also different, that is, the container material of the transformer oil (such as insulating paper, etc.) are different from the metal substances in contact with engine lubricating oil; in addition, the additives in transformer insulating oil and engine lubricating oil are also different; moreover, the possible pollutants in transformer insulating oil and engine lubricating oil It is also different. For example, the pollutants encountered by the transformer insulating oil may be water, while the pollutants that may be encountered by the engine lubricating oil include refrigerant fluid, fuel oil, etc.; based on the above reasons, the impurity products in the transformer insulating oil and the engine lubricating oil The impurity products in the two oils are different, so the criteria for evaluating the two oils are also different

[0009] And because the amount of insulating oil consumed by transformer equipment during normal operation is huge, and when the quality of transformer insulating oil declines, it will cause the transformer equipment to fail to operate normally, and even cause damage to the transformer equipment in severe cases, but for the replaced insulating oil No matter what method is used for recycling, huge economic losses and potential environmental pollution will be generated

[0010] Based on the above-mentioned problems and problems, the monitoring of the quality of transformer insulating oil and the technology of updating the quality of insulating oil have become difficulties in my country's power transmission and transformation industry, especially the difficulties and technical bottlenecks in the operation of my country's transmission and transformation grids and the construction of smart grids. Moreover, so far, the field has still not been able to come up with good solutions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0055] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

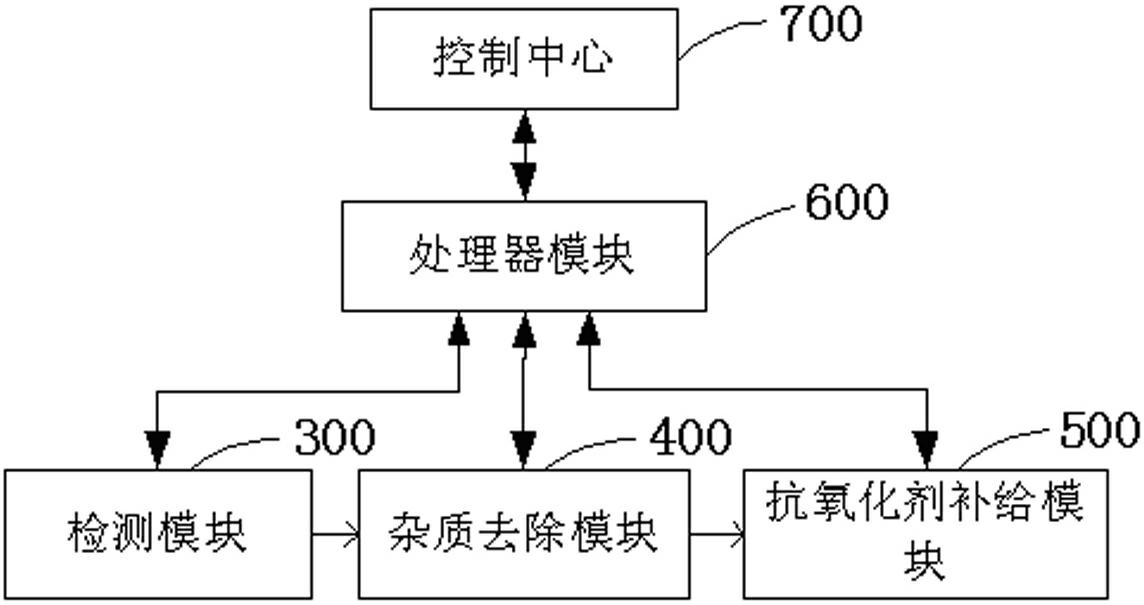

The invention relates to a method and a system for removing and supplying an antioxidant from / to transformer insulating oil impurities. Various chemical and physical components in transformer insulating oil are detected, and liquid impurities and solid impurities in the transformer insulating oil are removed according to a detection result, or an antioxidant is added into the transformer insulating oil, so that the quality of the transformer insulating oil is updated, reutilization of the transformer insulating oil is realized, the service life of the transformer insulating oil is prolonged, unnecessary environmental pollution is reduced, the replacing times of the transformer insulating oil are reduced, the working time of transformer equipment is prolonged, and the reliability of the transformer equipment is enhanced.

Description

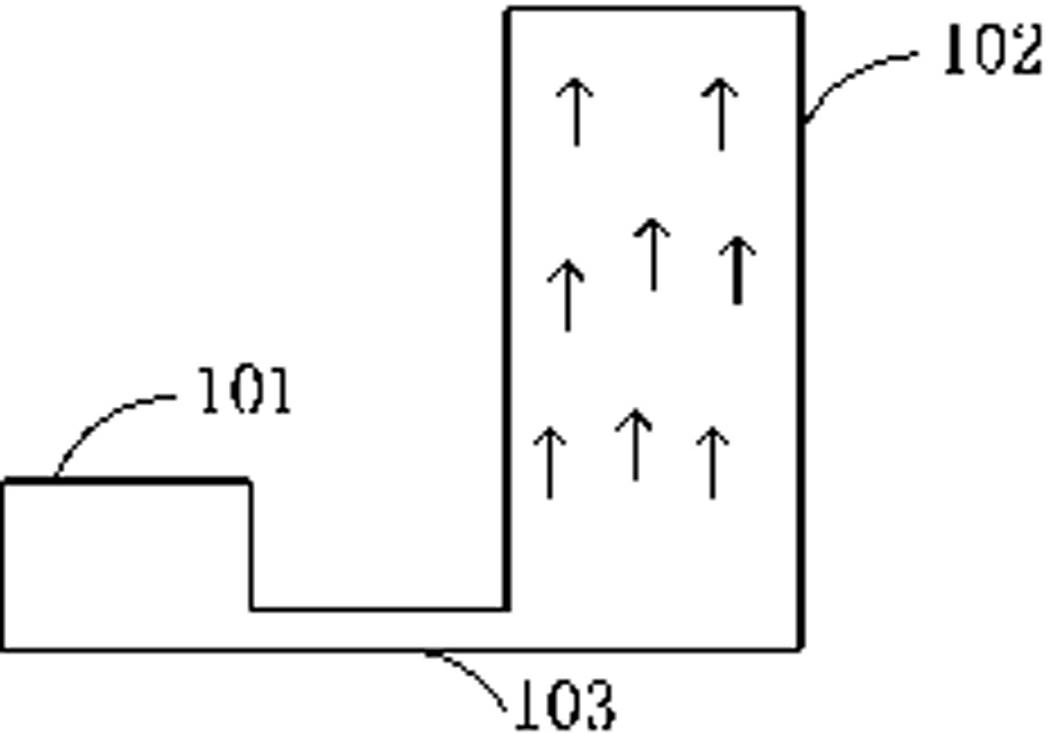

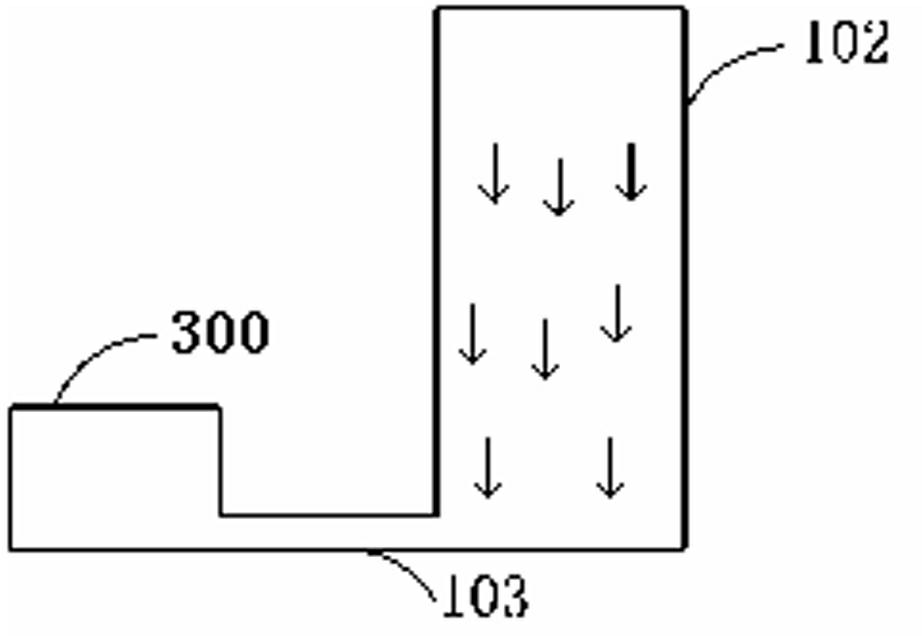

Technical field [0001] The invention relates to the monitoring and restoration of the quality of transformer insulating oil, in particular to a method and system for removing impurities in transformer insulating oil and replenishing antioxidants. Background technique [0002] Transformer insulating oil is usually made of highly refined lubricating oil as the base oil and then added with antioxidants. It is mainly used as the dielectric of electrical equipment. The main properties of transformer insulating oil are low temperature performance, oxidation stability and dielectric loss. Its low temperature performance means that under low temperature conditions, the oil can automatically convection in electrical equipment, dissipate heat and instantaneously cut off the fluidity necessary for arc current. Generally, electrical insulation oil is required to have low pour point and low viscosity at low temperatures; but In electrical equipment, oil is easily oxidized when it is exposed t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M177/00G01N33/30C10N40/16C10N30/10

Inventor 詹姆斯・刘

Owner BEIJING ANSAIBO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com