Sizing device of multi-layer and multi-wire large diameter steel wire rope

A steel wire rope and thick diameter technology is applied in the field of multi-layer multi-wire thick diameter steel wire rope sizing devices, which can solve the problems of difficult to adjust in place at one time, laborious and time-consuming adjustment, and difficult to control precision, so as to meet the precise requirements and reduce the use and maintenance. Cost, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

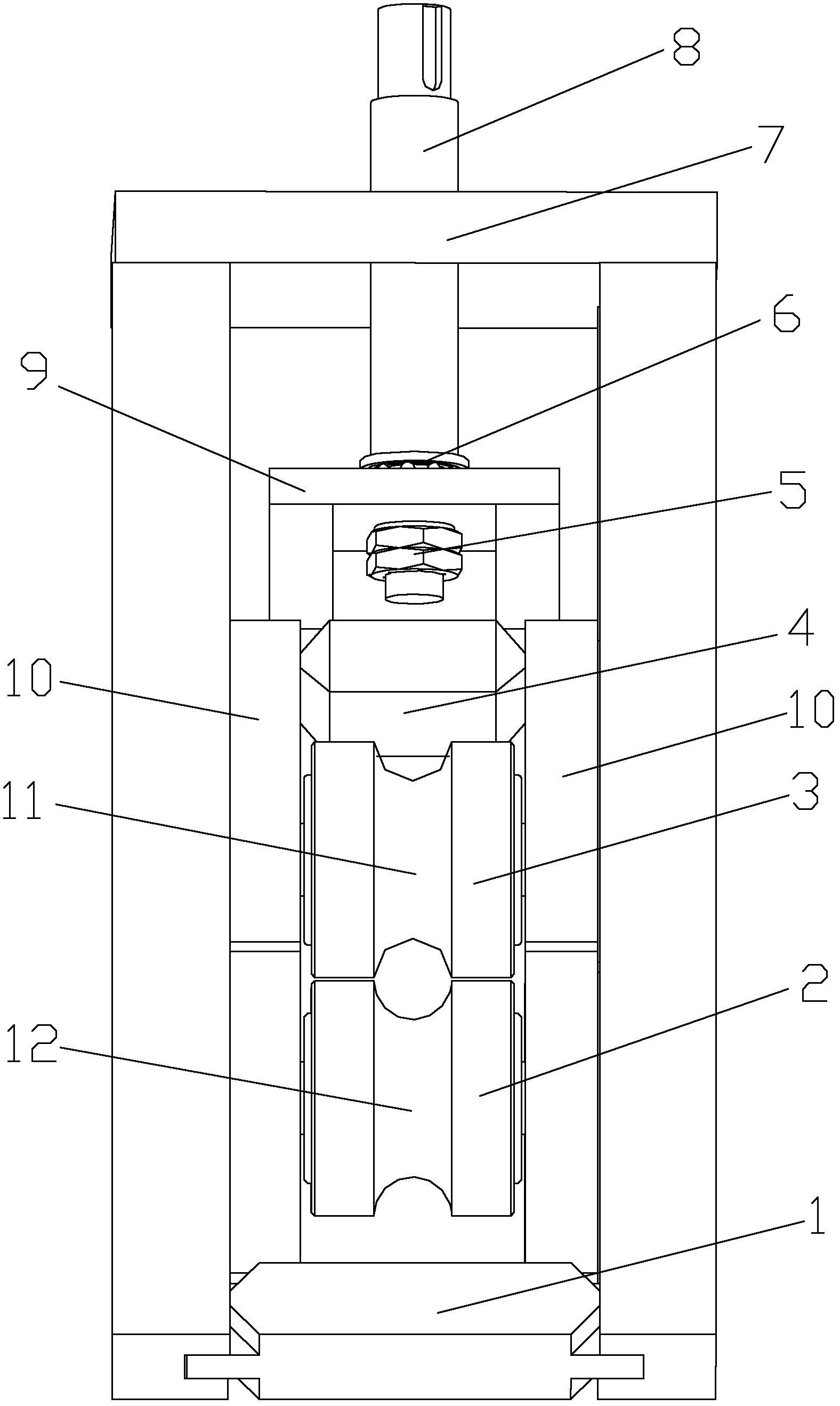

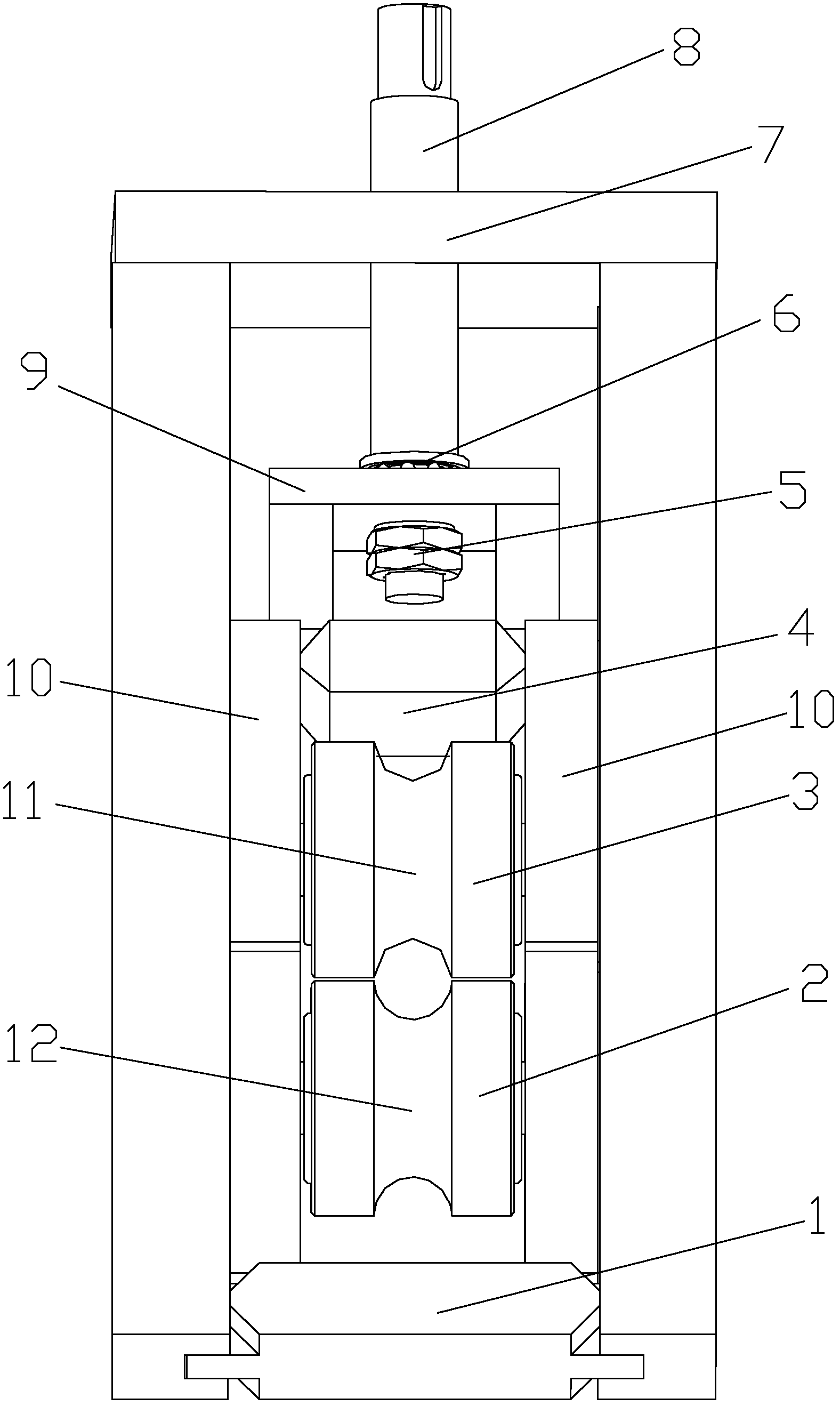

[0013] as attached figure 1 Shown is a multi-layer multi-filament thick-diameter steel wire rope sizing device of the present invention, comprising a lower adjustment block 1, a lower guide wheel 2, an upper guide wheel 3, an upper adjustment block 4, a U-shaped slideway 7, an adjustment screw 8, Slider 9, adjusting slideway 10, first semicircular groove 11, second semicircular groove 12; described adjusting slideway 10 is arranged in pair on the inner side of U-shaped slideway 7; described lower guide wheel 2, upper guide wheel 3 are respectively arranged on the adjustment slideway 10 through rotating shafts (not shown) arranged at their respective ends, and can move up and down along the adjustment slideway 10; the upper guide wheel 3 is arranged above the lower guide wheel 2; The lower adjustment block 1 is arranged below the U-shaped slideway 7 and below the lower guide wheel 2 to adjust the level of the lower guide wheel 2; the adjustment screw 8 passes through the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com