Fastener structure for adjusting track gauge

A technology for adjusting components and gauges, applied in tracks, fixed rails, roads, etc., can solve the problems of soft gauge pads, low toughness of product materials, and reduced product use effects, and achieve small gauge adjustment errors. Simple way to achieve overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

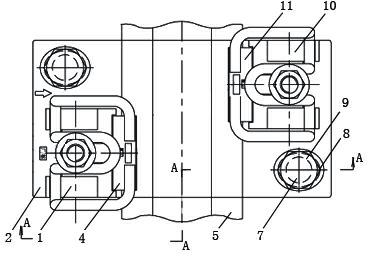

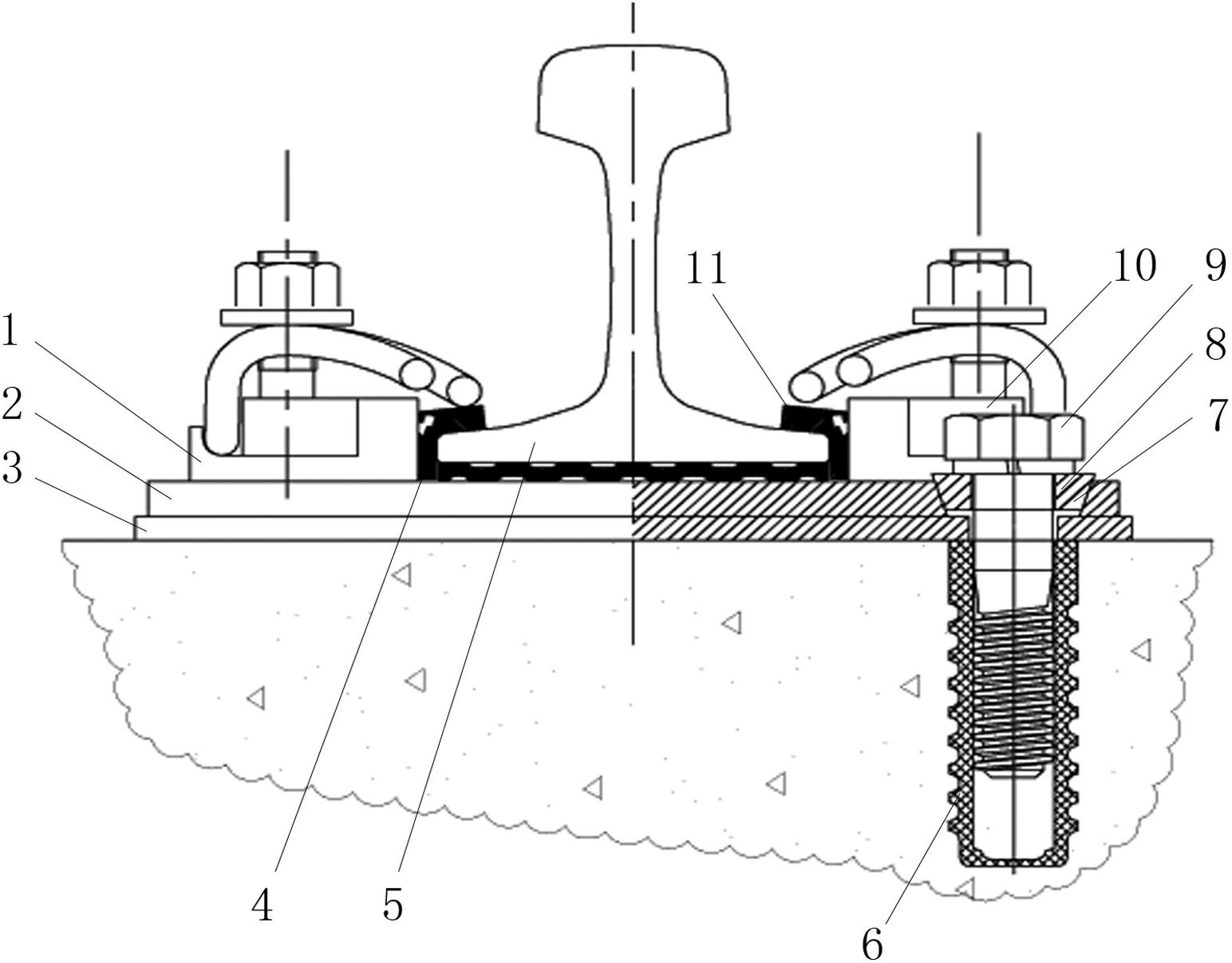

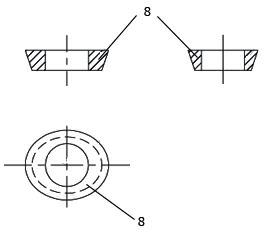

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 A fastener structure for adjusting the gauge is shown, which includes: an iron backing plate 2, a left iron seat 1 and a right iron seat 10 fixed on the iron backing plate 2, which are relatively arranged on both sides of the rail 5, and located on the iron backing plate 2. The left and right iron bases 1, 10 are buckled on the left L-shaped gauge pad 4 and the right L-shaped gauge pad 11 on the rail 5. The iron backing plate 2 is placed on the sleeper through the backing plate 3, and the left 1. The two L-shaped sides of the right L-shaped gauge pad 4 and 11 are of different thicknesses, and the two sides of the left L-shaped gauge pad 4 and the two sides of the right L-shaped gauge pad 11 have a difference in thickness between each two sides 1 to 3 mm, the adjacent matching positions of the left and right fasteners 1 and 10 are provided with adjustment components 7; the adjustment components 7 are composed of gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com