Joint for track panel and manufacturing and installing method

A technology of end and section steel, which is applied in the direction of track, track laying, track maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

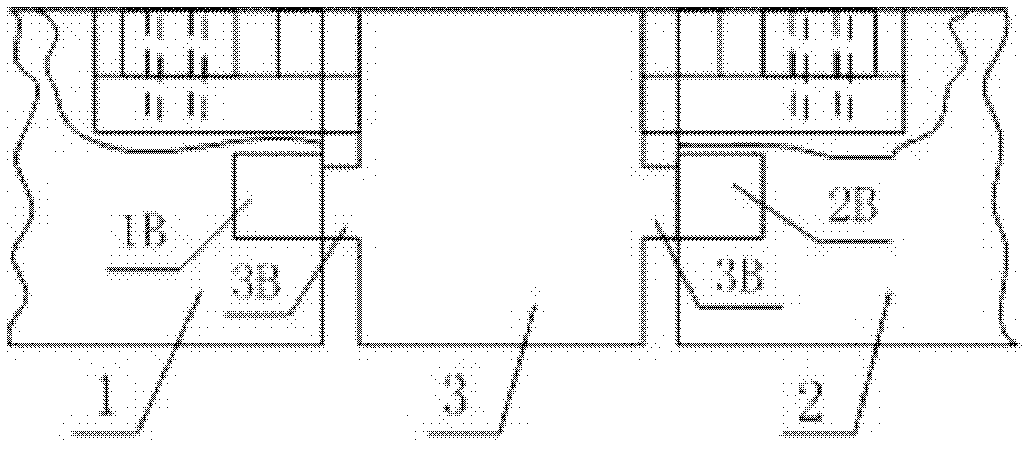

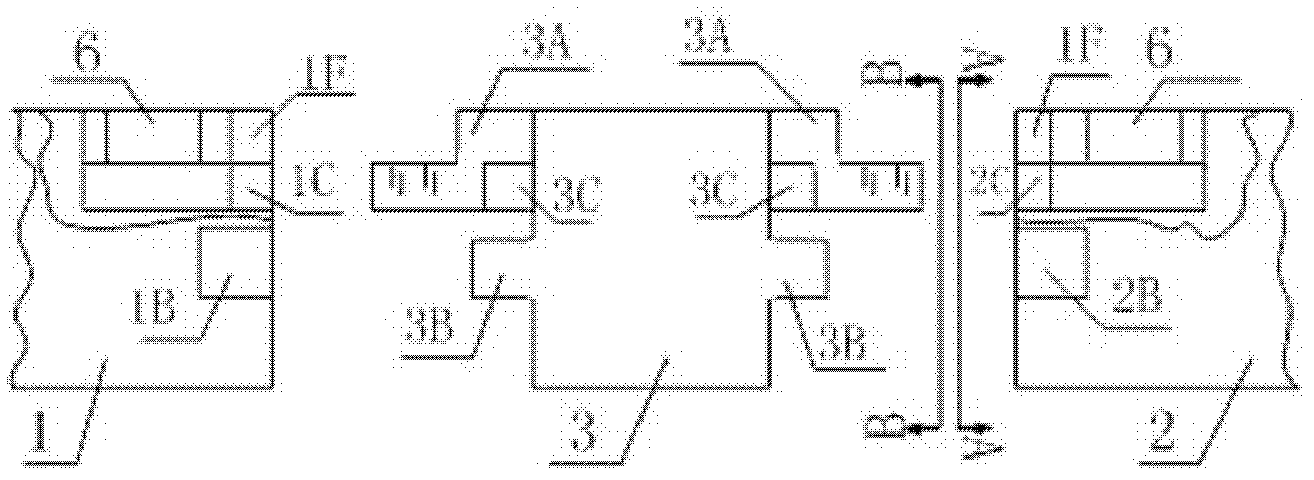

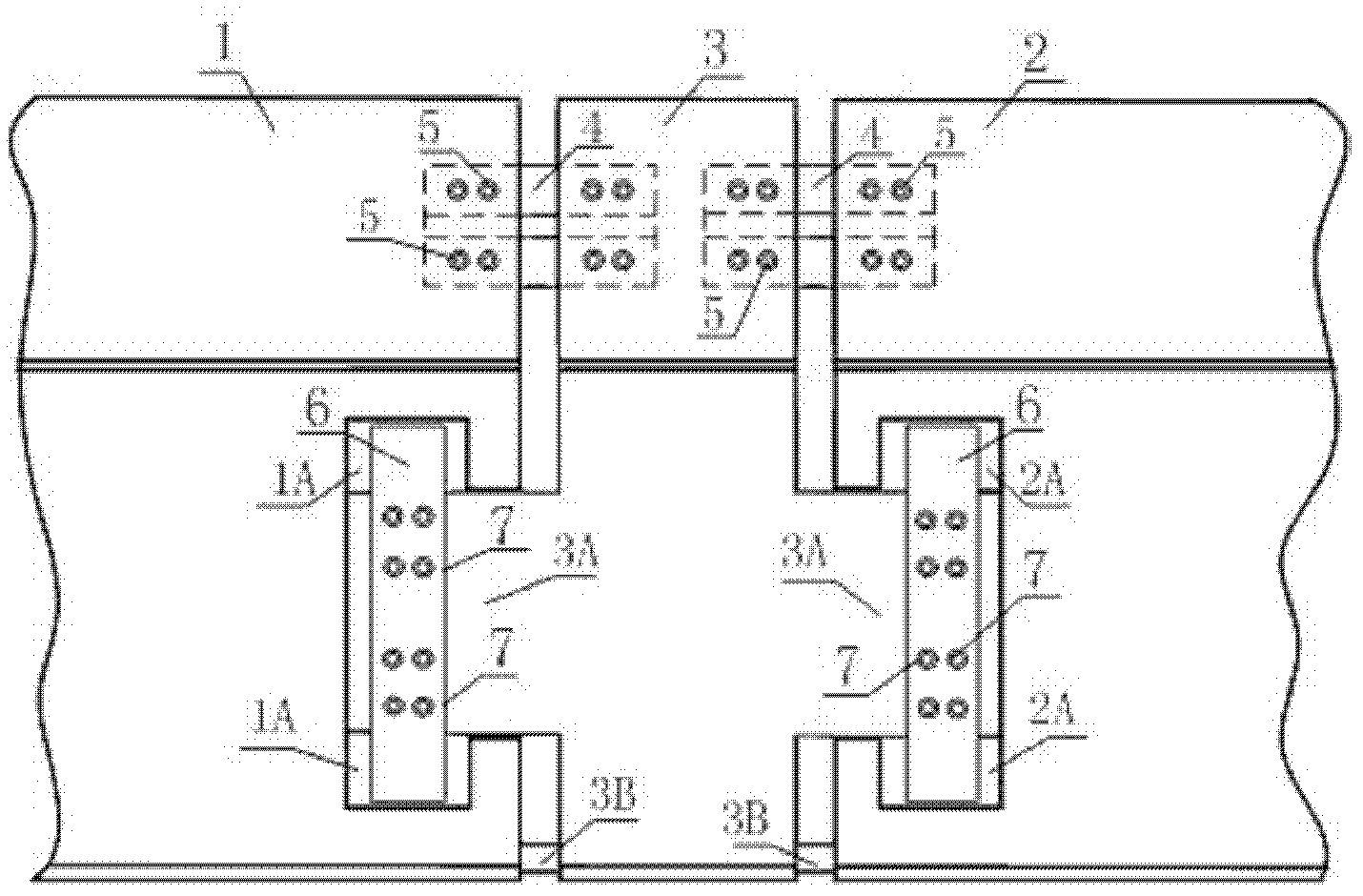

[0052] A rail row joint for medium and low-speed maglev trains, which consists of front F-shaped steel 1, rear F-shaped steel 2, middle F-shaped steel 3, single-key slider 4, slider bolt 5, and supporting slide plate 6. The front F-shaped steel 1 and the rear One end of the F-shaped steel 2 is processed into a mirror-symmetric groove structure, and the two ends of the middle F-shaped steel 3 are processed into a mirror-symmetrical convex plate structure. The processing ends of the front F-shaped steel 1, the middle F-shaped steel 3, and the rear F-shaped steel 2 are similar Correspondingly arranged in order from front to back, two pairs of corresponding wing plates are connected together by two connecting single-key sliders 4 and connecting slider bolts 5, and two pairs of corresponding wing plates are connected by two supporting sliders 6 and countersunk head bolts 7. The corresponding groove structure is connected with the convex structure to form an F-rail joint as a whole. ...

Embodiment 2

[0077] The front chute support plate 1A and the rear chute support plate 2A are as Figure 4 As shown, it is a pair of rectangular grooves with exactly the same size, which are located on the webs of the two opposite ends of the front F-shaped steel 1 and the rear F-shaped steel 2, and the distance from the ends of the front F-shaped steel 1 and the rear F-shaped steel 2 is equal to the front The width of the baffle plate 1F and the rear baffle plate 2F; its depth is equal to the thickness of the supporting slide plate 6; its width is the width of the supporting slide plate 6 plus 2 times the front and rear expansion; its length is about the width in the F-shaped steel web groove (see Figure 5 ), its main function is to make the supporting slide plate 6 slide back and forth in the groove after being connected with the web slide plate 3A with countersunk bolts 7 in the front chute support plate 1A and rear chute support plate 2A, The sliding amount is equal to the designed exp...

Embodiment 3

[0093] The front chute support plate 1A and the rear chute support plate 2A are as Figure 4 As shown, it is a pair of rectangular grooves with exactly the same size, which are located on the webs of the two opposite ends of the front F-shaped steel 1 and the rear F-shaped steel 2, and the distance from the ends of the front F-shaped steel 1 and the rear F-shaped steel 2 is equal to the front The width of the baffle plate 1F and the rear baffle plate 2F; its depth is equal to the thickness of the supporting slide plate 6; its width is the width of the supporting slide plate 6 plus 2 times the front and rear expansion; its length is about the width in the F-shaped steel web groove (see Figure 5 ), its main function is to make the supporting slide plate 6 slide back and forth in the groove after being connected with the web slide plate 3A with countersunk bolts 7 in the front chute support plate 1A and rear chute support plate 2A, The sliding amount is equal to the designed exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com