Waterproof connection method for coils

A connection method and coil technology, which can be used in earth drilling, water conservancy projects, building insulation materials, etc., can solve the problems of lack of waterproof function, cumbersome operation, and water seepage at joints, and achieve good waterproof and leakproof effects. Solve the effect of cumbersome operation and reliable connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

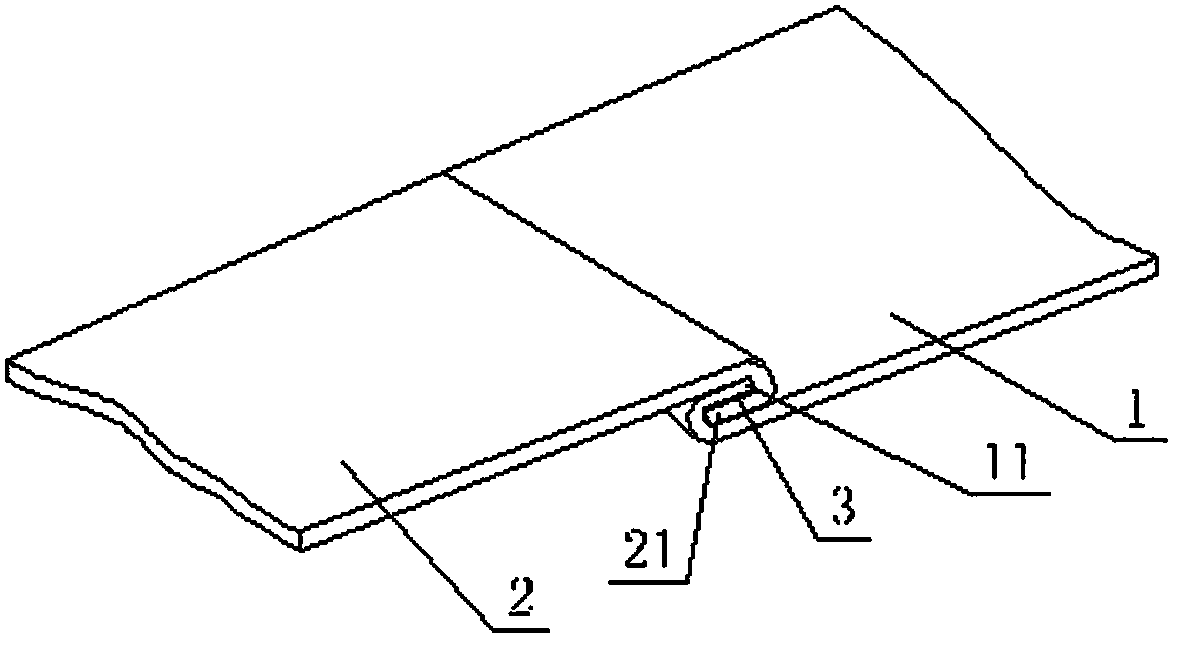

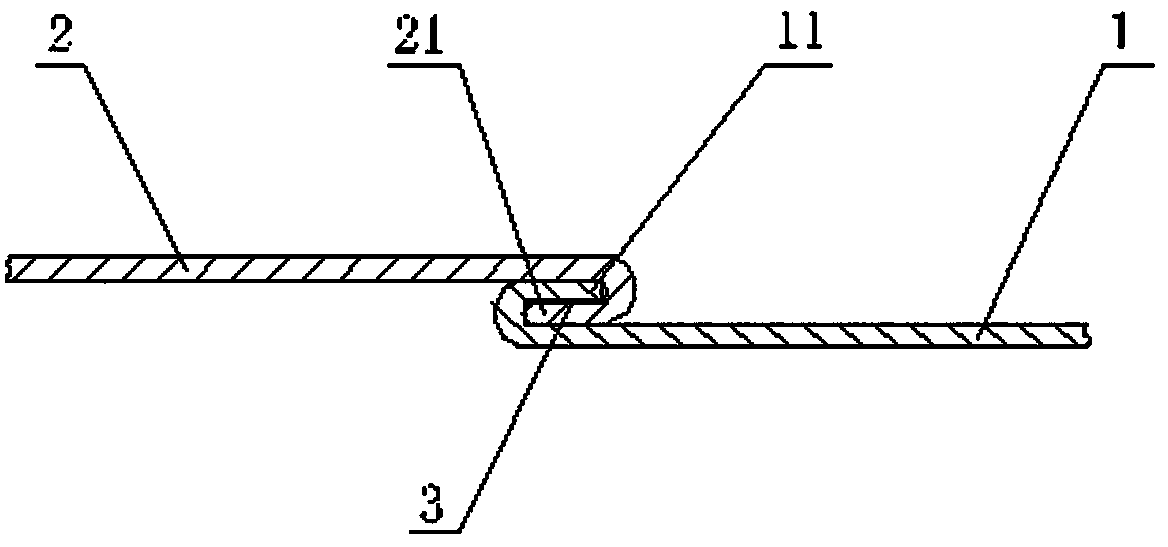

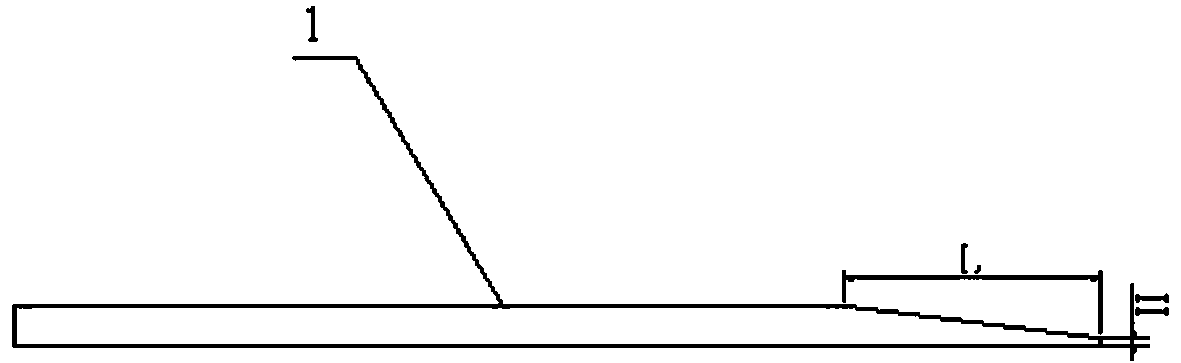

[0015] Such as Figure 1-Figure 5 As shown, the waterproof connection method of the coiled materials in the present invention is: the two connecting ends of the coiled materials 1 and 2 are connected together by hooking up and down or coiled, so as to realize the waterproof and waterproof of the two connecting ends of the coiled materials 1 and 2. Leaky connection. When two or more rolls are laid on the base of the building to form a complete waterproof layer, since the connecting ends of the adjacent two rolls are connected by upper and lower hooks or rolls Together, the joints that are prone to water penetration and water seepage at the joints of the two connection ends are wrapped in the joints. During use, neither the water above the coil nor the water below the coil can pass through the joint. The seams ooze out, and the waterproof connection structure is extremely reliable. Figure 5 It is a structural schematic diagram of the present invention after the two coils 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com