Screen cloth position detection device and equipment

A detection device and screen technology, which is applied in construction, building structure, and construction material processing, can solve the problems of detection structure failure, increase maintenance intensity and requirements, and signal inaccuracy, so as to improve accuracy and safety , The effect of reducing the failure rate of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

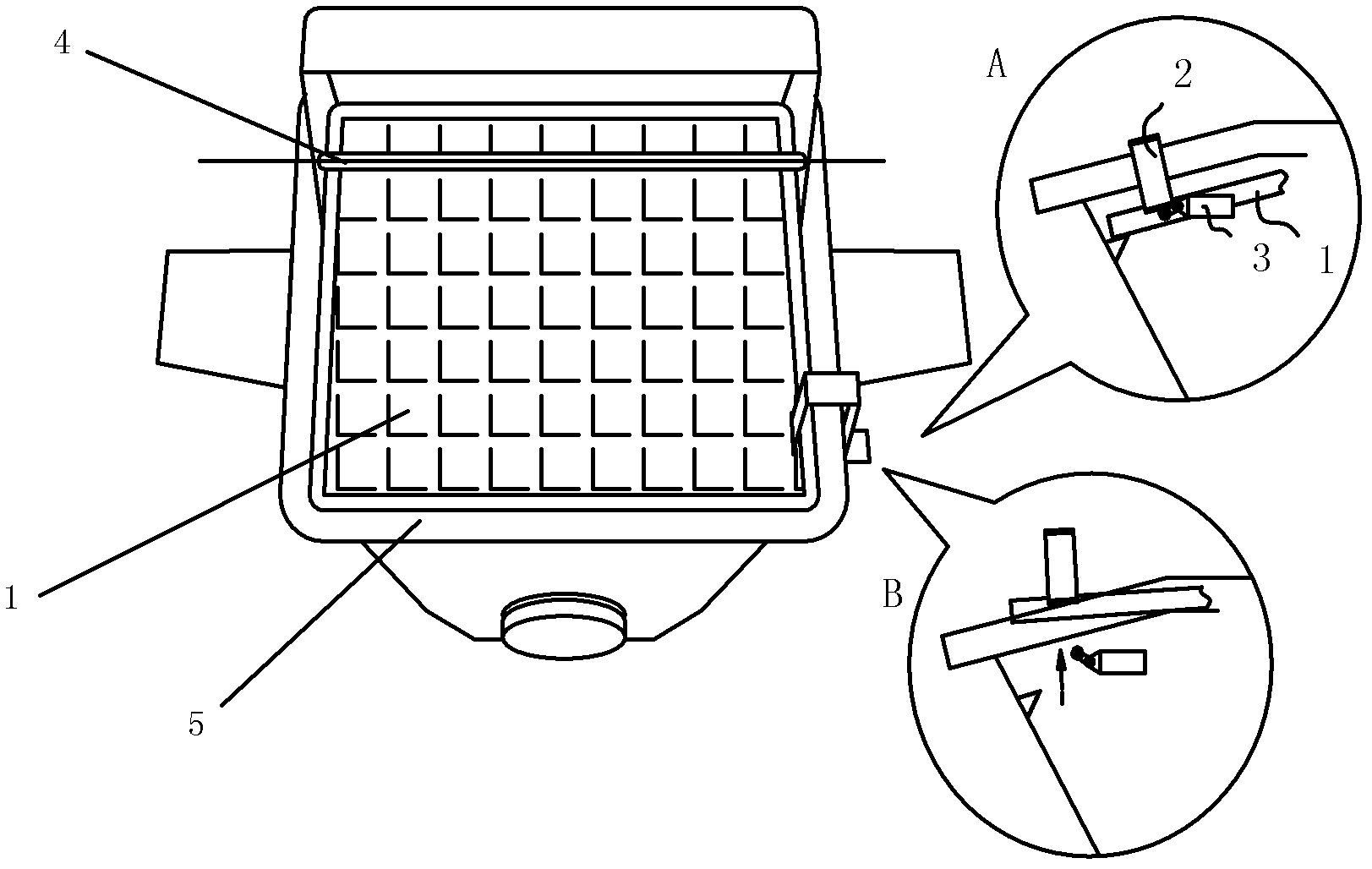

Image

Examples

Embodiment Construction

[0018] In the embodiment of the present invention, the proximity switch and the corresponding induction block are used to detect the position of the screen in the concrete pump truck. Since the proximity switch is a non-contact switch, the failure rate of the device caused by the application environment can be reduced, and the screen position can be improved. The accuracy of the detection further improves the safety of the concrete pump truck.

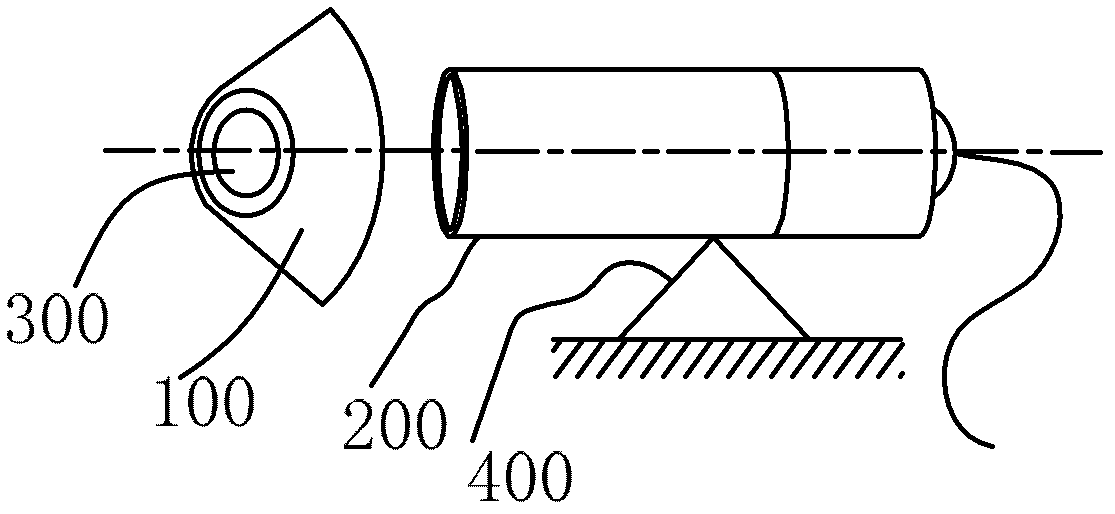

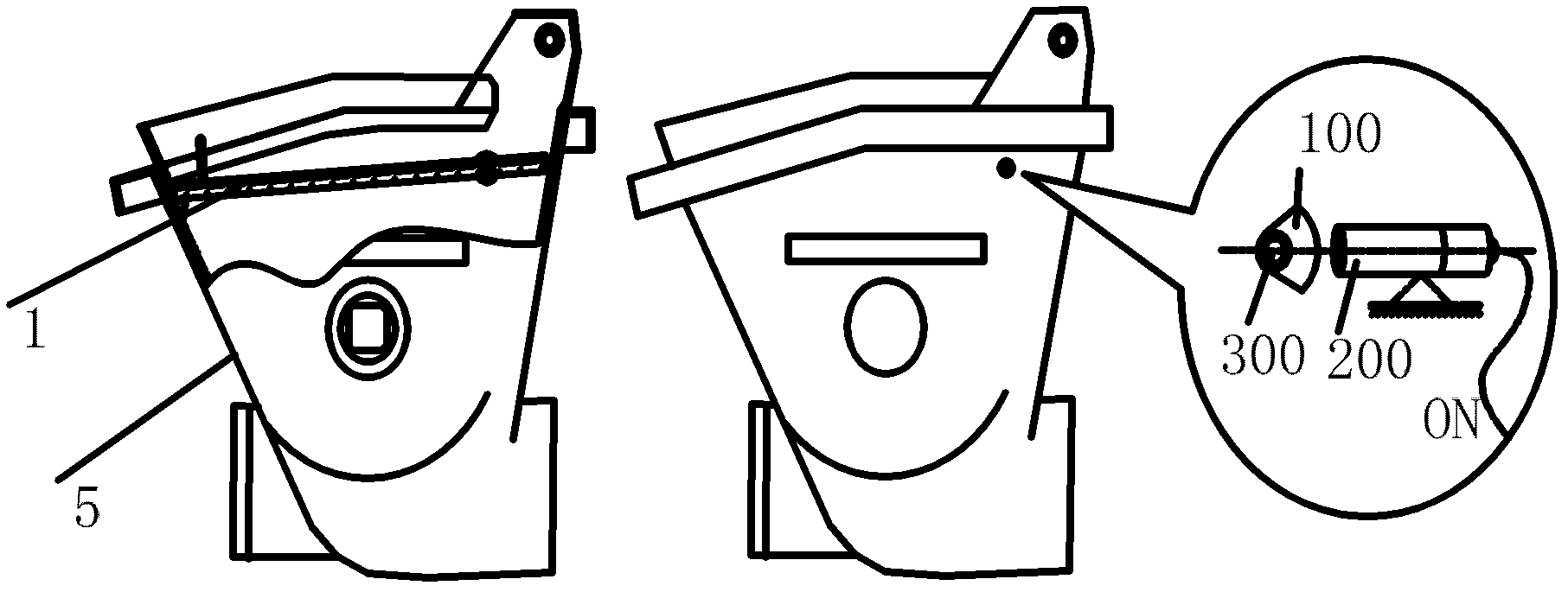

[0019] See figure 2 In the embodiment of the present invention, the screen position detection device includes: an induction block 100 and a proximity switch 200, wherein,

[0020] The sensing block 100 is fixedly connected to the first position of the screen rotating shaft 300 and can rotate with the screen rotating shaft 300. Among them, the screen shaft 300 is used to connect the screen of the concrete pump truck and the hopper.

[0021] The proximity switch 200 is located in a second position opposite to the first position on the hopper....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com