Gate mechanism

A movement and gate technology, which is applied to mechanical equipment, transmission parts, roads, etc., can solve the problem of small internal space of cylindrical rotating column swing gates, difficulty in meeting the layout requirements of cylindrical rotating column swing gates, It is inconvenient to route the electric control cables and other problems, so as to solve the wiring problem, reduce the size of the gate, and improve the matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail through embodiments in combination with the drawings.

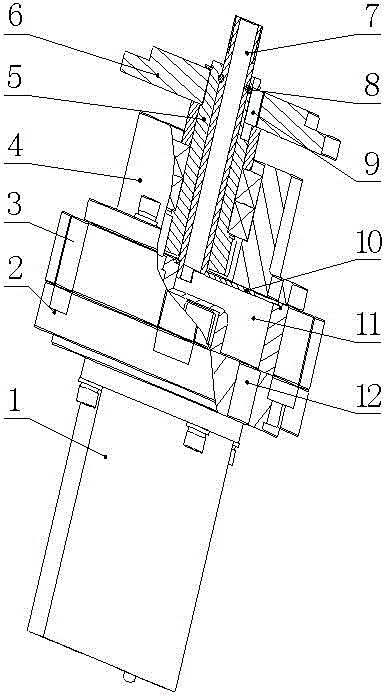

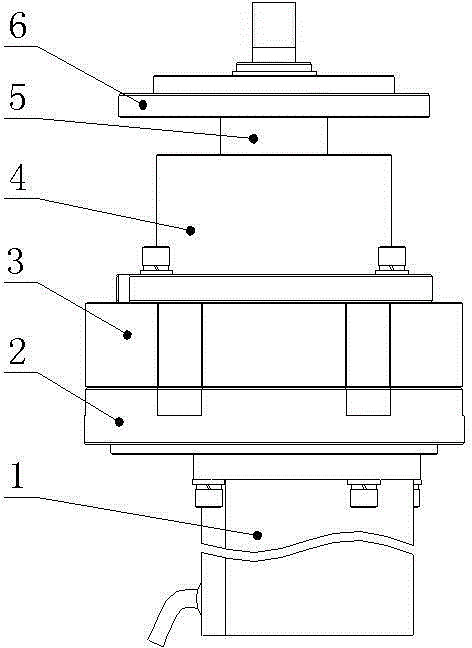

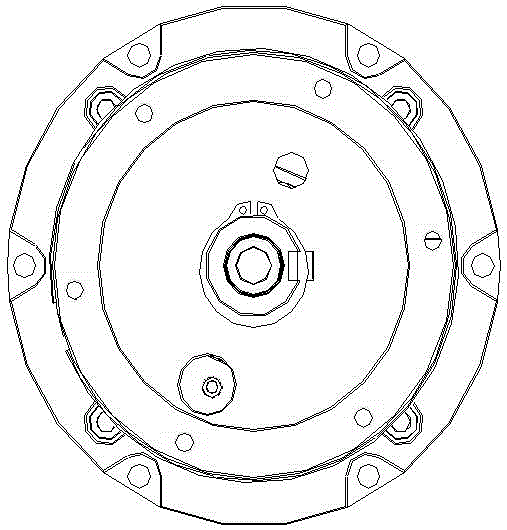

[0021] See figure 1 with image 3 The gate movement is, for example, a movement for channel gates. In one embodiment, the movement includes a motor 1, a reducer, and an output flange 6. The reducer includes a cylindrical reducer housing, internal gears and connections. The output gear shaft assembly 5 of the output flange is arranged concentrically with the reducer case.

[0022] Such as figure 1 As shown, in a preferred embodiment, the movement further includes a wire passing device arranged inside the reduction box body.

[0023] See Figure 1 to Figure 3 In a preferred embodiment, the reduction box body includes a cylindrical lower box body 2, a middle box body 3 and an upper box body 4. The shapes of the three boxes are circular and concentrically arranged, which is convenient for processing and positioning. The lower box body 2 is preferably de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com