Pipe fixing device with multiple holes

A technology of fixing devices and porous tubes, which is applied in the direction of pipe brackets, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of affecting the aesthetics of the cabin, increasing the number of brackets, and uneven gaps, so as to facilitate assembly and maintenance. The layout is beautiful and the effect of reducing the assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

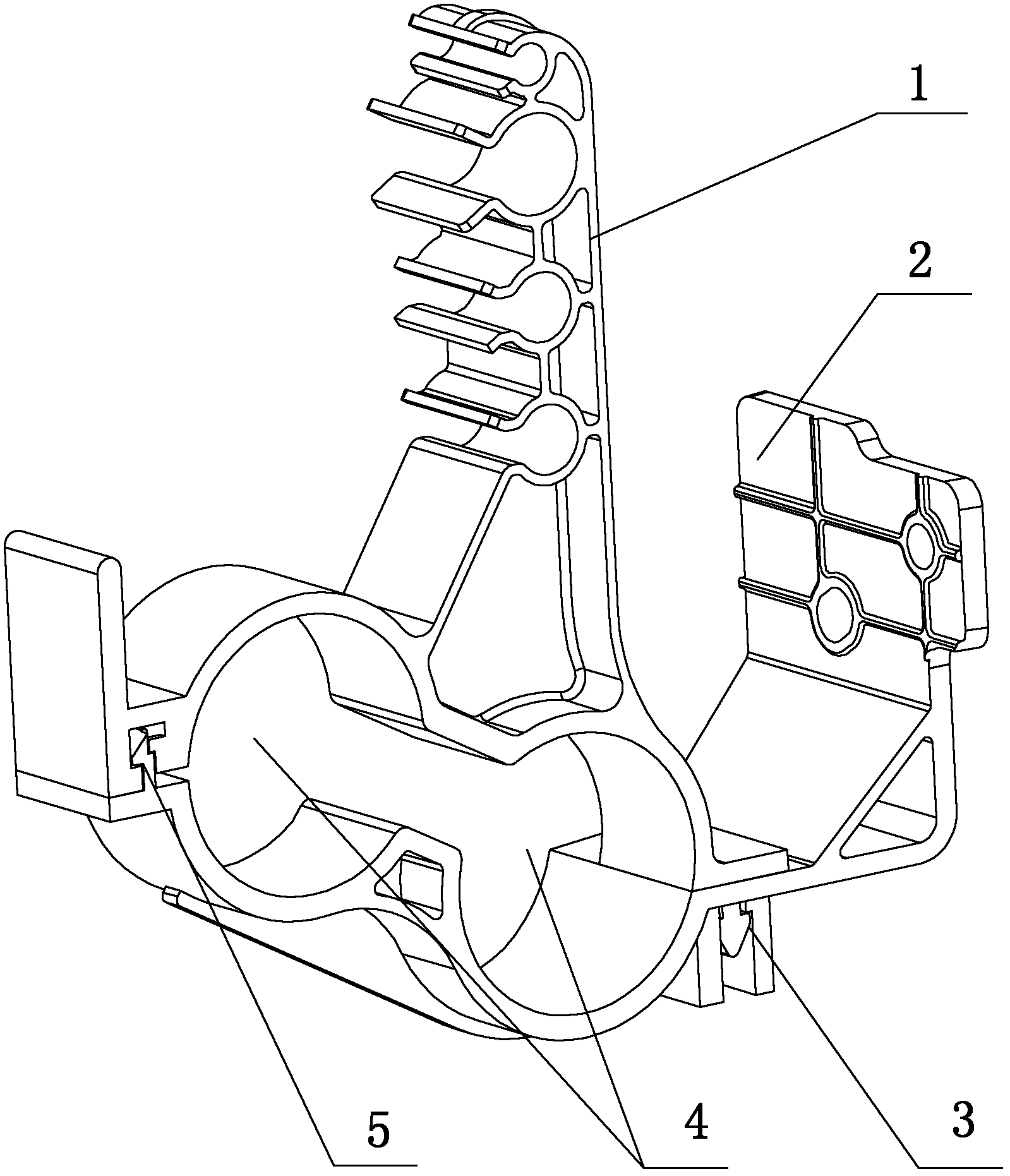

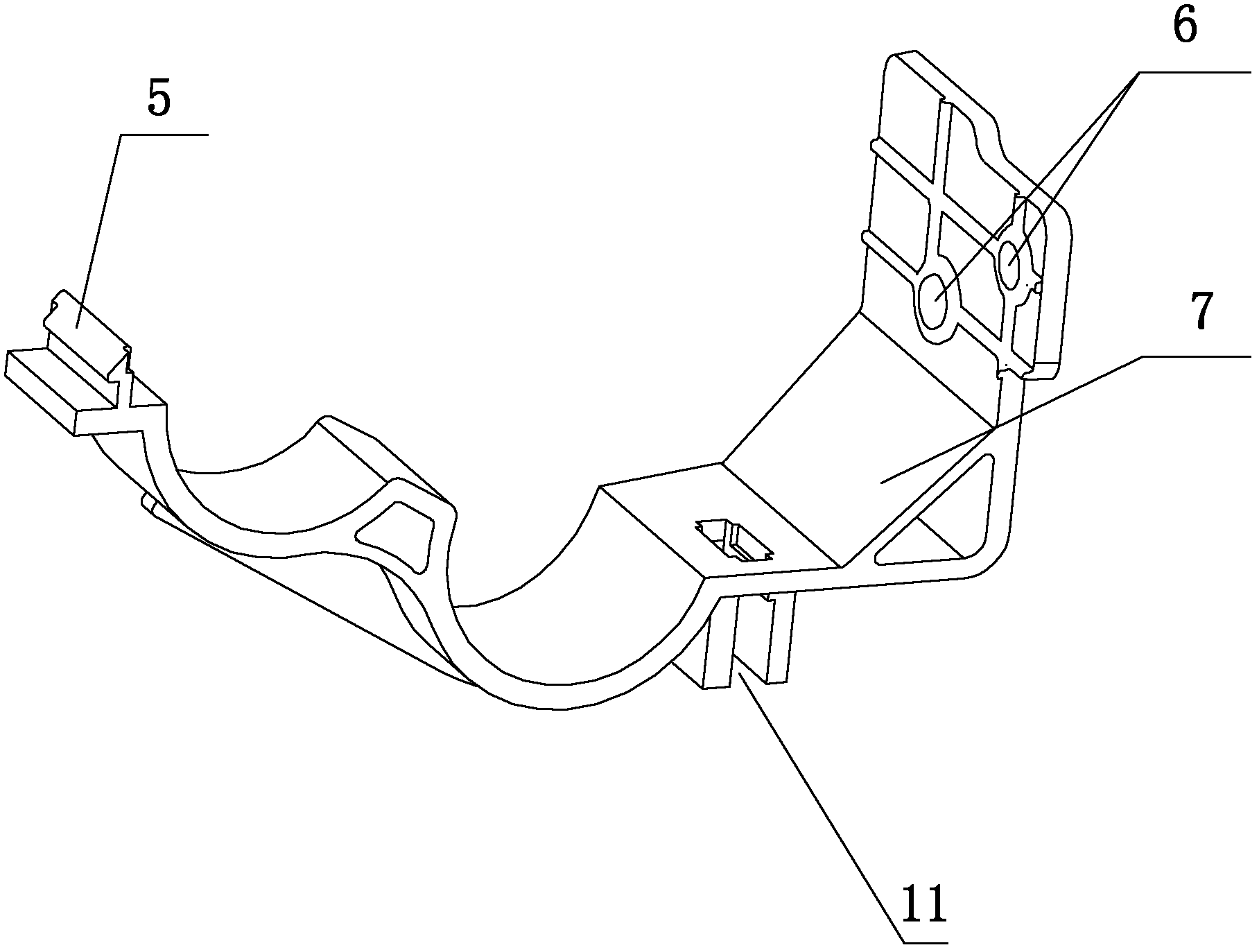

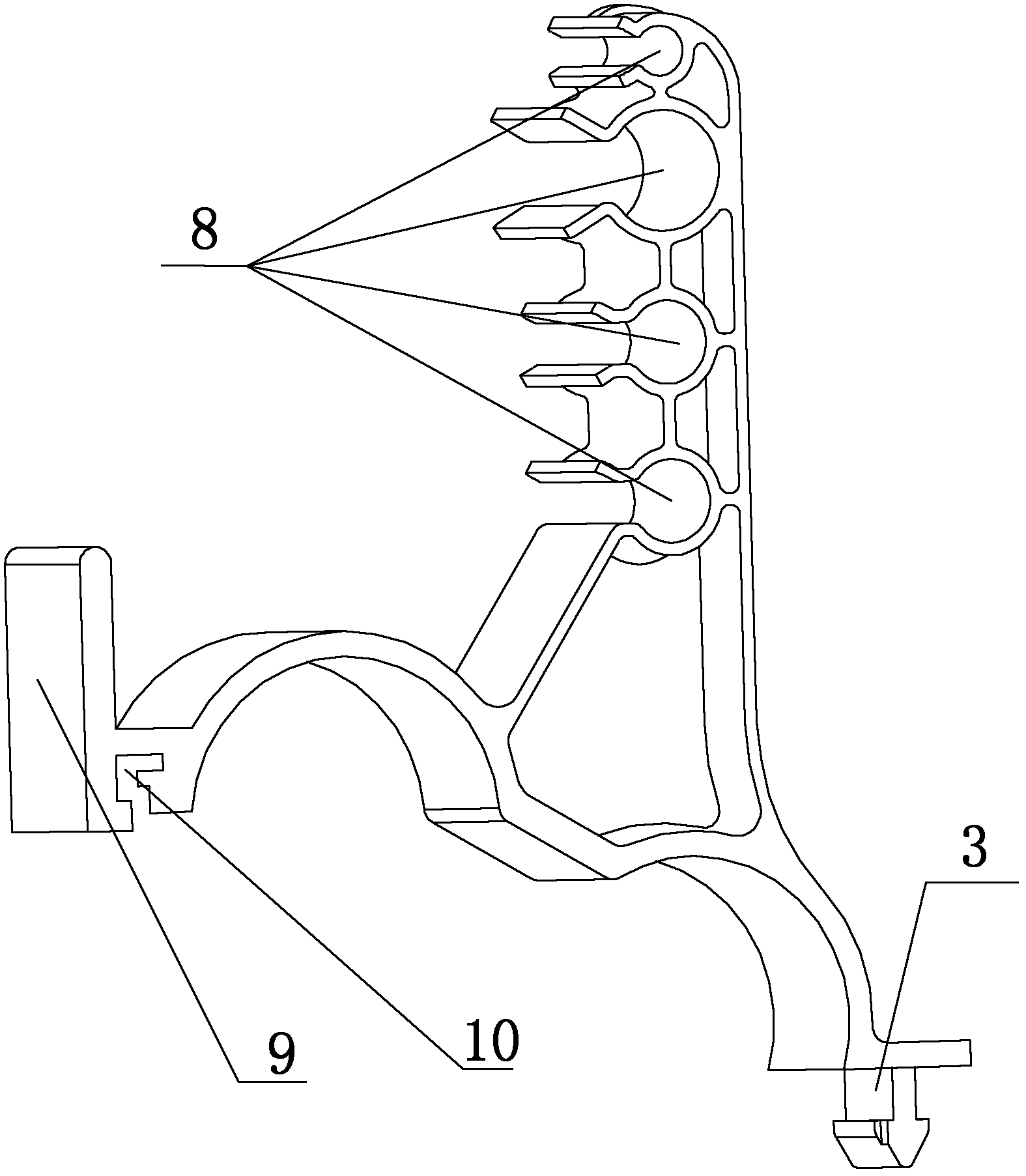

[0016] Such as Figure 1-5 As shown, a porous pipe fixing device described in the embodiment of the present invention includes a pipe clamp upper part 1 and a pipe clamp lower part 2 fixedly connected to the engine casing, and a pipe clamp upper part 1 and a pipe clamp lower part 2 are formed. A number of circular pipe clamp holes 1, wherein the top of the pipe clamp upper part 1 is uniformly provided with a number of pipe clamp holes 2 8, the left end of the pipe clamp upper part 1 is fixed with a disassembly flange 9, and the bottom surface of the pipe clamp upper part 1 is close to the disassembly flange 9 places are provided with a card slot 10, the bottom surface of the upper part 1 of the pipe clamp is provided with a card angle 3, the card angle 3 passes through the lower part 2 of the tube clamp and is stuck in the groove 11 on the bottom surface of the lower part 2 of the tube clamp, and the lower part 2 of the tube clamp There is a clamping angle 2 5 near the left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com