Air-permeable anchored vacuum heat-insulation plate and manufacturing method thereof

A vacuum insulation panel and anchoring technology, which is used in heat exchange equipment, mechanical equipment, and pipeline protection through thermal insulation, etc., to achieve the effect of expanding the scope of use, improving adaptability and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

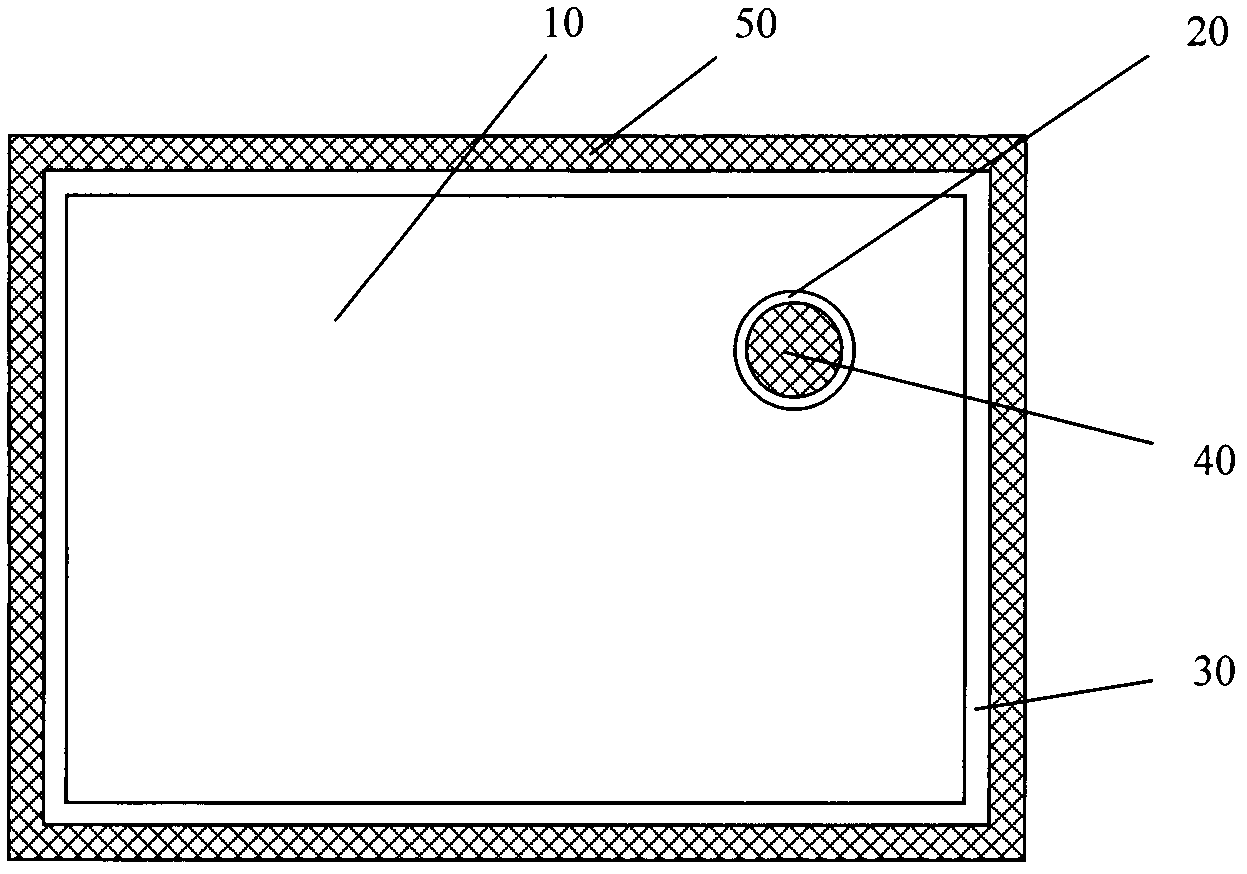

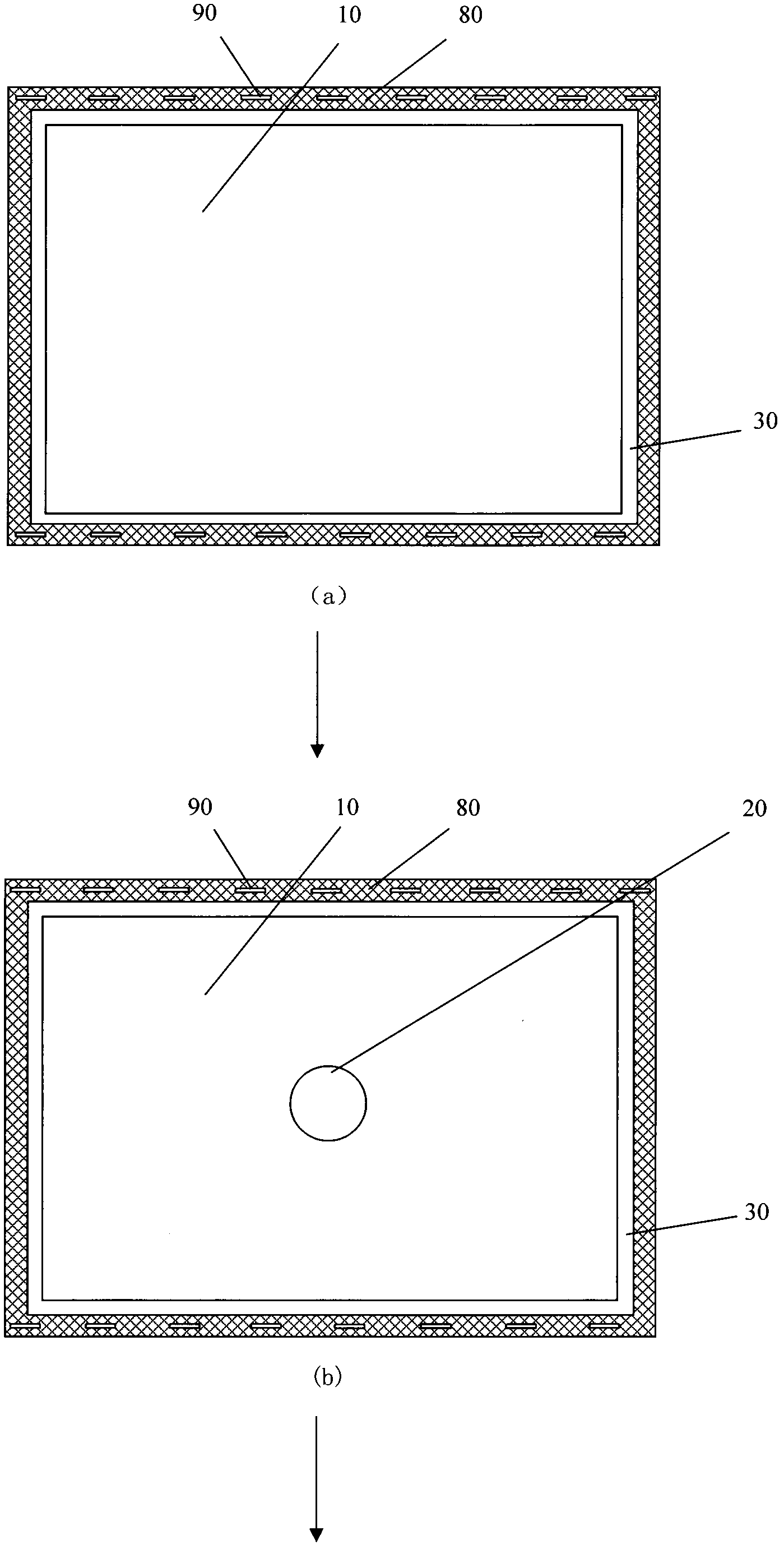

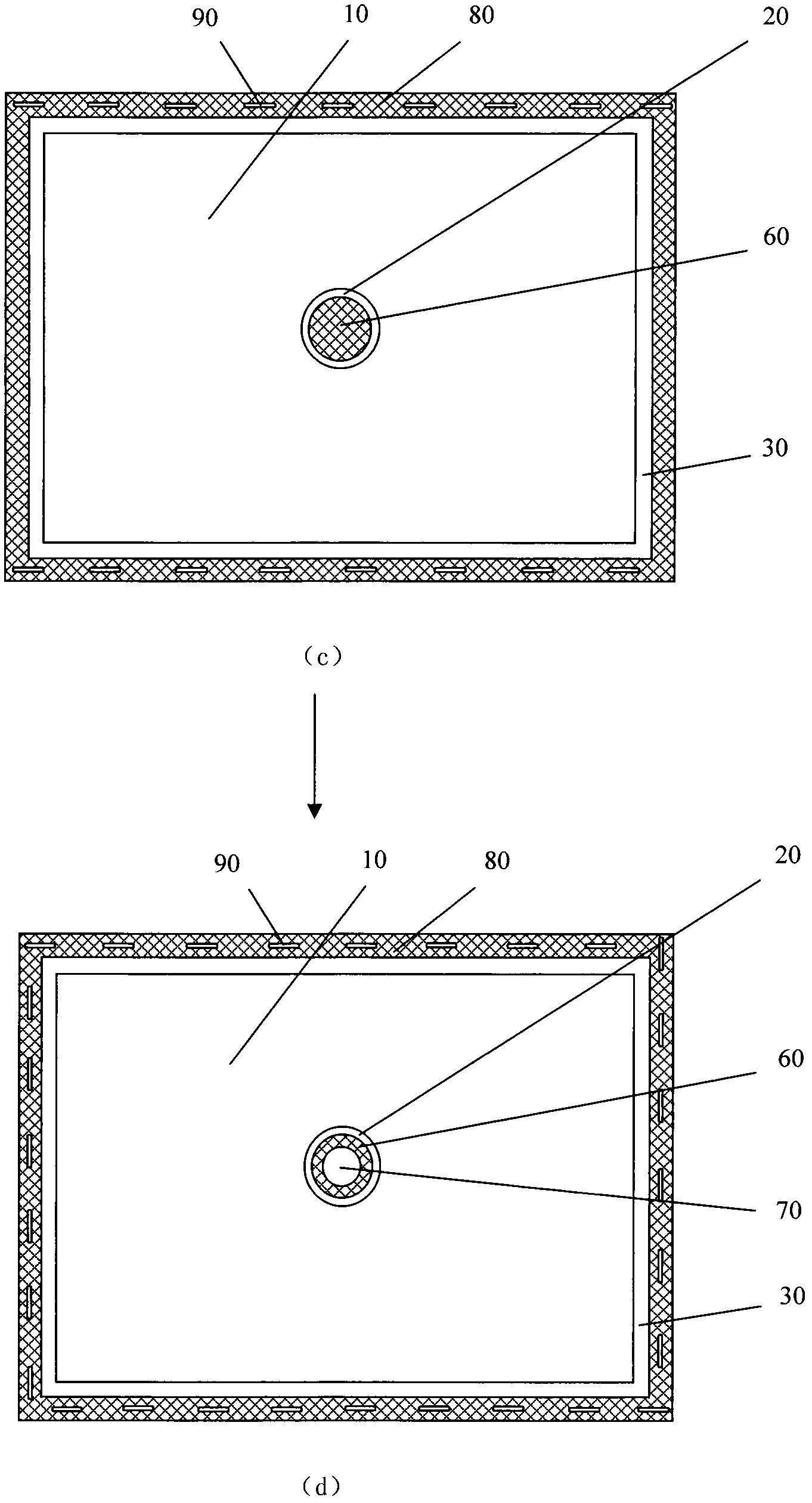

[0036] refer to figure 2 , a breathable anchored vacuum insulation panel described in this embodiment includes: a core material 10, a core material punching area 20, a vacuum packaging barrier film 30, an annular heat sealing area 60 in the panel, and a circular mechanical punching area in the panel 70 . Barrier film heat sealing area 80 , rectangular hole 90 .

[0037] When the vacuum insulation panel is prepared, the specific process steps are as follows:

[0038] (1) heat-seal the three sides of the vacuum packaging barrier film, and leave a hole on the fourth side for filling the core material and vacuuming;

[0039] (2) Mechanical punching at the heat-sealed edge, the rectangular hole is 8mm long and 3mm wide, and the hole interval is 80mm and evenly distributed to form a vacuum-encapsulated barrier film with rectangular holes on the side heat-sealed edge.

[0040] (3) The core material is perforated by a circular hole puncher, and the hole is located in the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com