Needle tube oil burning boiler with energy-saving economizer

A technology for oil-fired boilers and economizers, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve problems such as uneconomical, and achieve the effects of reducing operating costs, improving economic operation levels, and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

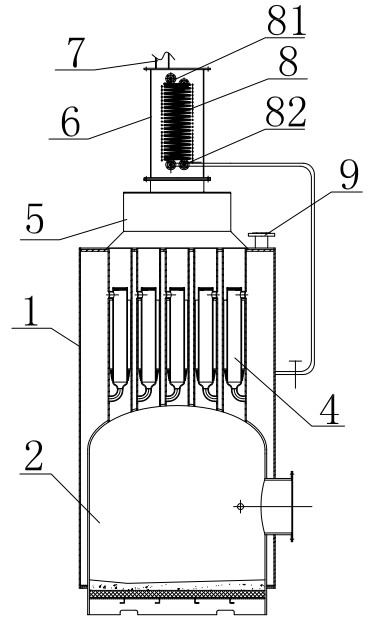

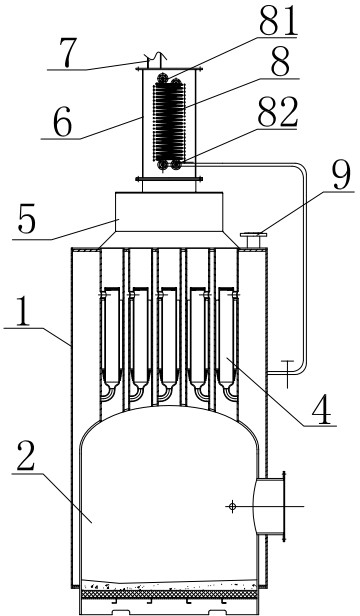

[0009] Such as figure 1 As shown, the structure of the needle-shaped tube oil-fired boiler with an energy-saving economizer mainly includes: a shell 1, a furnace 2 is arranged inside the shell 1, and a number of needle-shaped tube assemblies 4 are connected to the top of the furnace 2. The shell 1 A smoke box 5 is arranged on the top, and the top of the needle tube assembly 4 communicates with the smoke box 5. The top of the housing 1 is also provided with a steam outlet 9, and the smoke box 5 is connected with an energy-saving economical The structure of the energy-saving economizer includes: an energy-saving economizer housing 6, the bottom of the energy-saving economizer housing 6 communicates with the smoke box 5, and the energy-saving economizer housing 6 is connected with an exhaust pipe 7, which is energy-saving and economical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com