Humidifier

A humidifier and accommodating chamber technology, applied in ultrasonic humidifiers, air humidification systems, heating methods, etc., can solve the problem that water vapor cannot penetrate very easily, and achieve the effect of improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

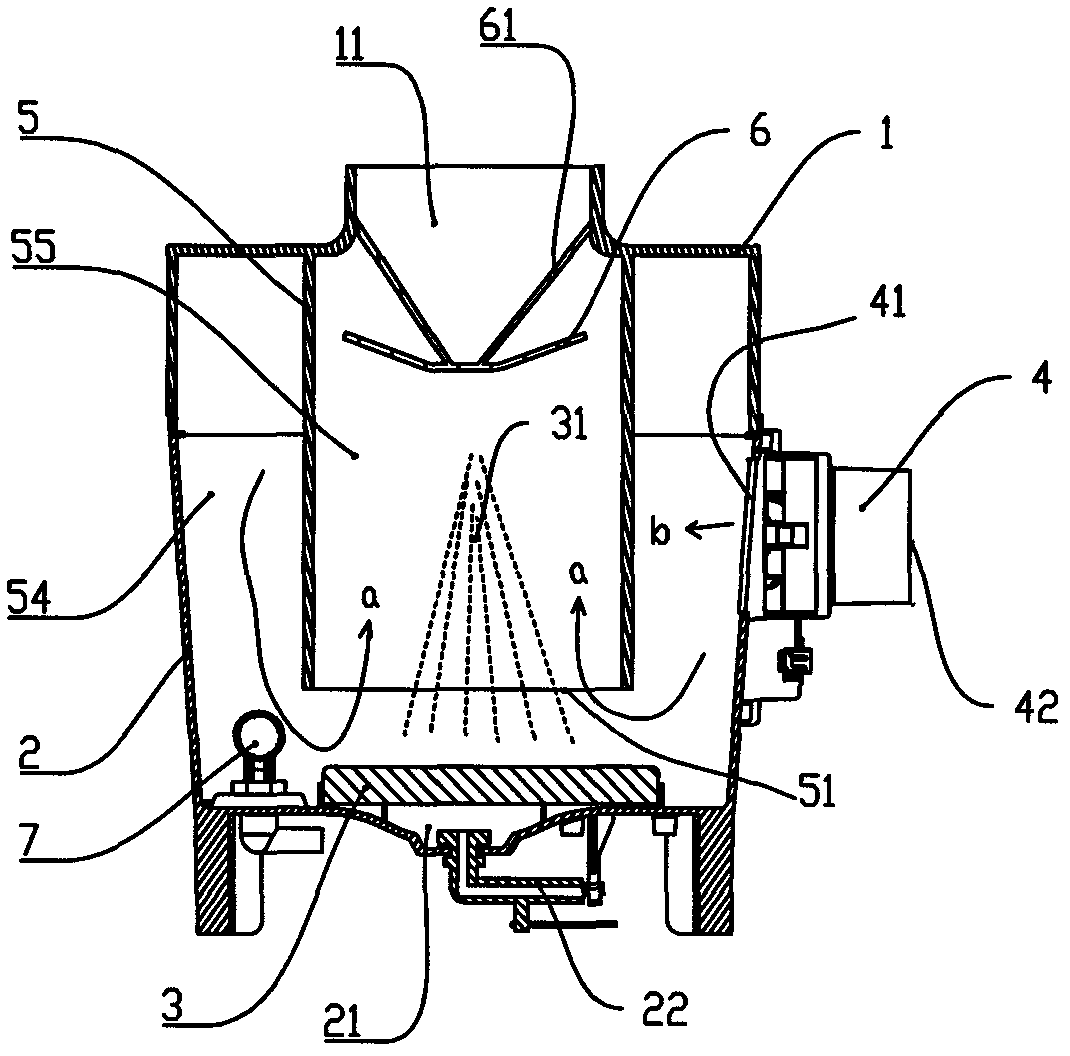

[0028] Such as figure 1 As shown, a humidifier includes an accommodating chamber that can accommodate the atomized liquid, and the accommodating chamber is composed of a liquid holding chamber 2 located below and a cover body 1 covering the liquid holding chamber 2 . The cover body 1 is provided with the mist outlet 11, the inner bottom of the liquid holding chamber 2 is provided with an ultrasonic atomization generator 3 and a float valve 7, and a water inlet (not shown in the figure) is also provided. ). The float valve 7 controls the liquid level of the liquid such as water contained in the liquid holding chamber 2 .

[0029]The cover body 1 is fixedly connected with the mist guide chamber 5 which communicates with the mist outlet 11 and extends to the bottom of the liquid holding chamber 2. The mist guide chamber 5 and the corresponding ultrasonic atomizer The generator 3 is located at the center of the containing cavity.

[0030] The space contained in the mist guiding...

Embodiment 2

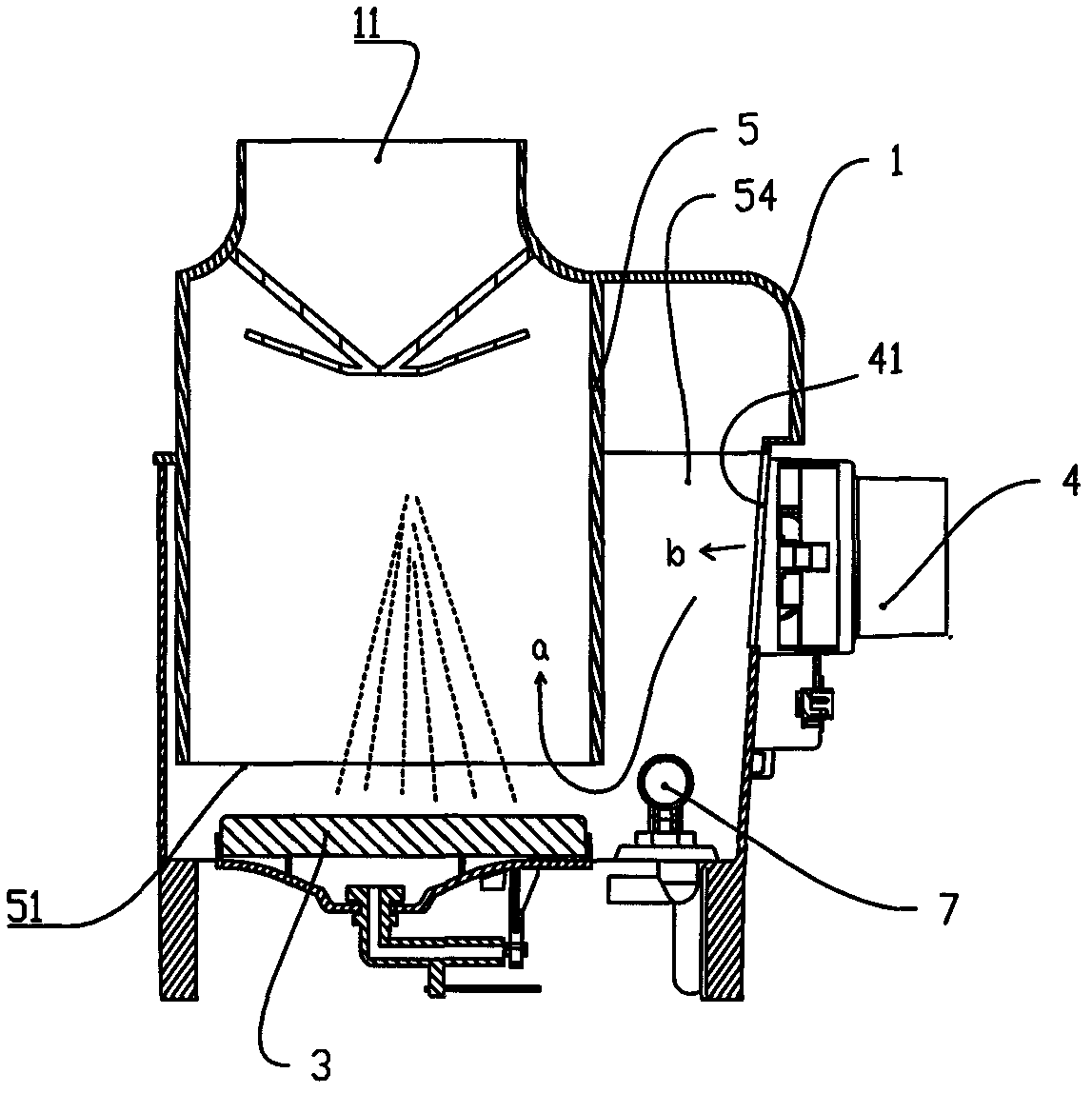

[0039] Such as figure 2 As shown, the difference from the first embodiment is that the mist guiding chamber 5 and the corresponding ultrasonic atomization generator 3 are located at a side position in the accommodating chamber.

Embodiment 3

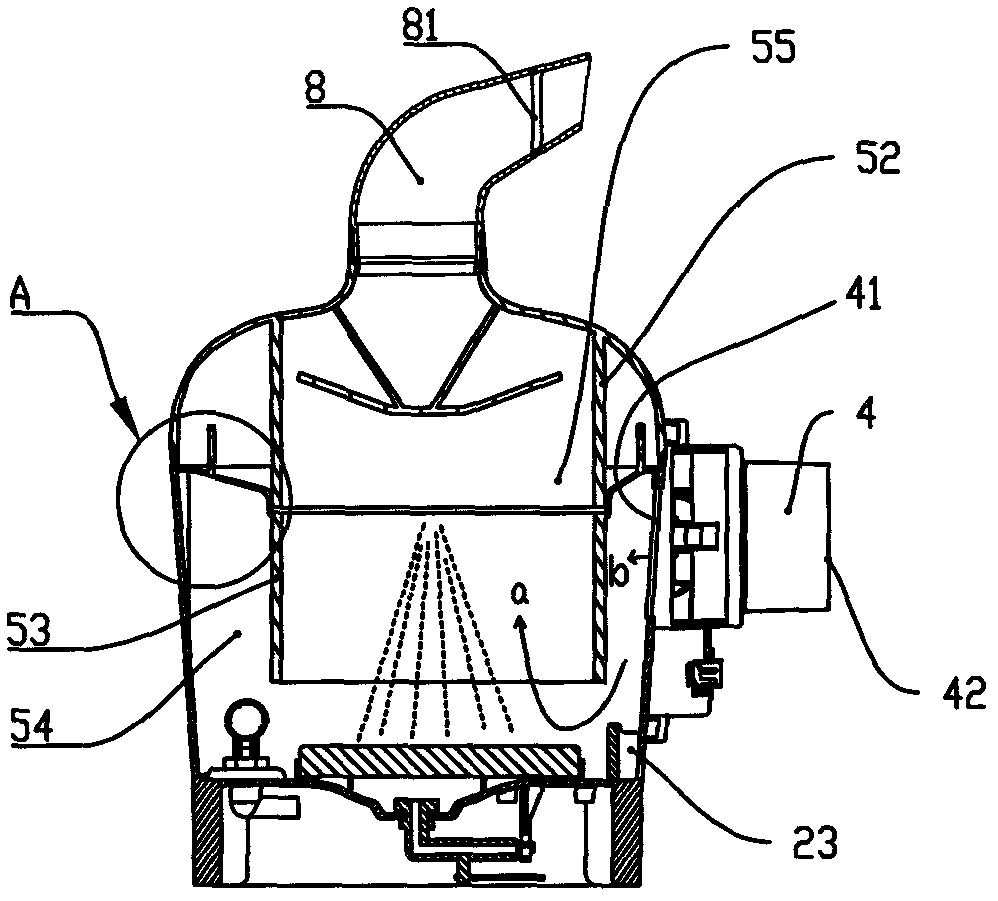

[0041] Such as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that the mist guiding chamber 5 includes a lower channel 53 and an upper channel 52 that are butted up and down. The top skirt 56 of the lower passage 53 is connected to the wall of the liquid holding chamber 2 ; the upper passage 52 is located in the cover 1 and connected to the cover 1 . The skirt 56 covers the upper opening of the liquid holding chamber 2 . In this way, the mist guiding chamber 5 can be manufactured in two stages, thereby reducing mold manufacturing costs without affecting the performance that the mist guiding chamber 5 should have. Secondly, since the lower passage 53 is connected to the wall of the liquid holding chamber 2, the ability of the wall of the liquid holding chamber 2 to bear impacts can be improved.

[0042] A mist guiding pipe 8 is arranged on the upper part of the mist outlet 11, and a grille 81 is arranged inside the mist guiding pipe 8, and the grille 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com