Flexible single crystal Lamb wave resonator and method of forming same

A single crystal Lamb wave resonator, flexible technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of reduced device performance, device scrapping, unevenness, and achieve the effect of improving the success rate of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

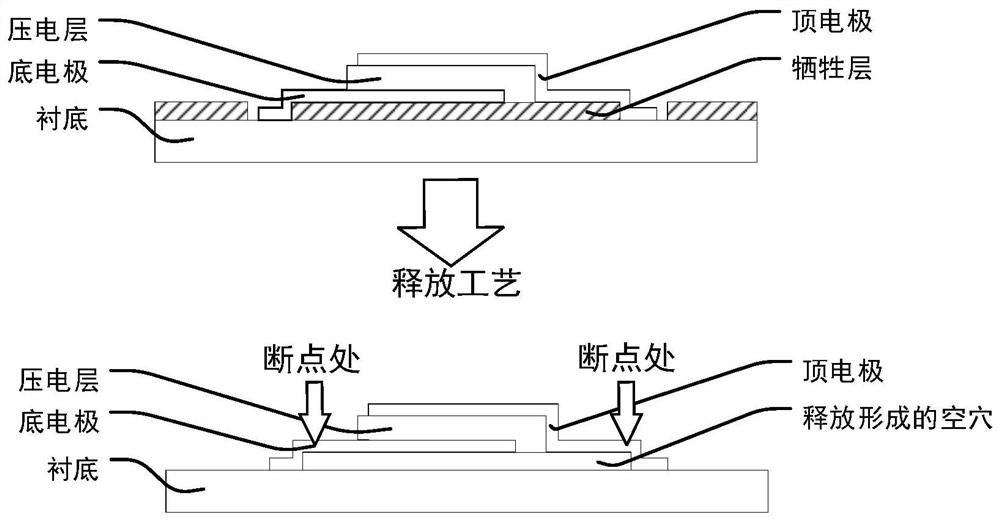

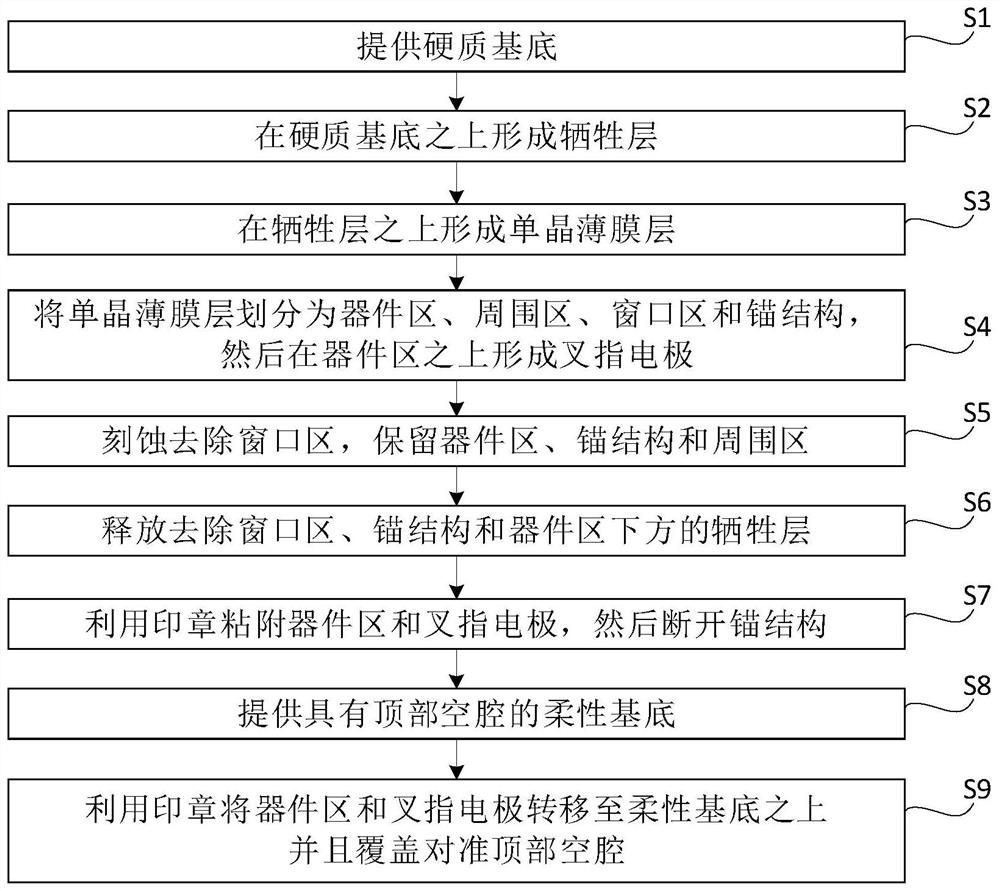

[0055] The hard substrate 101 having a silicon material having a thickness of about 400 μm is provided, and a sacrificial layer 102 having a thickness of from 0.1 to 10 μm (preferably 1 μm) is formed over the hard substrate 101 by a chemical vapor deposition process, and then by ion The slice process is a single crystal thin film layer 103 of a lithium niobic acid lithium niobate material having a thickness of 0.1 to 2 μm (preferably 0.7 μm) above the sacrificial layer 102.

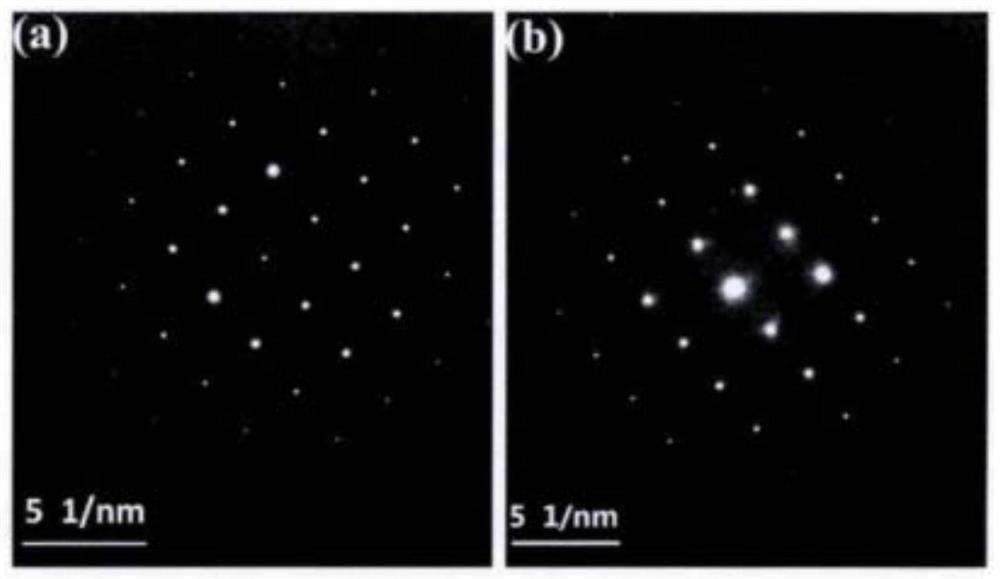

[0056] It is to be explained that the ion slicing process specifically refers to the front injection of the lithium niobate wafer + Ion, make HE + Ions are injected into a certain depth of the lithium niobate wafer and form a HE + Ion layer, then by heating annealing process makes he + The HE molecule bubbles are formed, thereby peeling the film layer. Finally, the lithium niobate film layer was thinned to a designated thickness of 0.1 to 2 μm to 0.7 μm using a chemical mechanical polishing (CMP) process. The...

Embodiment 2

[0068] First, the next order is formed in order Figure 14 The four-layer structure shown, including a hard base layer 101, a sacrificial layer 102, a metal layer 107 (thickness of about 0.1 μm), and a single crystal film layer 103. Then, a single crystal film region division, etching window, and release cavity will be performed in the steps in Example 1. The release process removal of the device structure after the silica of the sacrificial layer 102 is Figure 15 As shown, the bottom electrode 107 'is formed below the device area 103a. Continue with reference to the step of the step in Example 1, the resonator structure is transferred from the hard substrate to the flexible substrate with top cavities. The final device is like Figure 16 Indicated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com