Lateral force detector for four wheels of automobile

A detector and lateral force technology, applied in the field of vehicle inspection, can solve problems such as cumbersome steps, long measurement time, and reduced riding comfort, and achieve the effect of simplifying measurement steps and saving measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

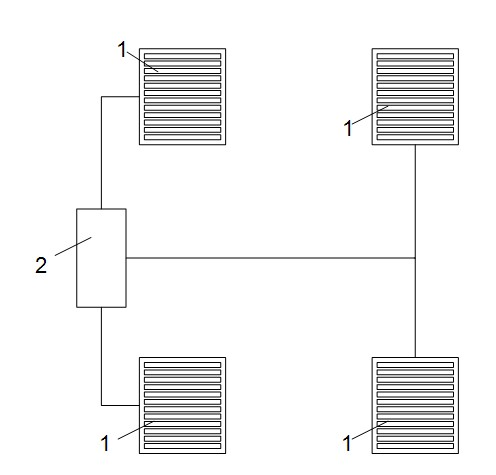

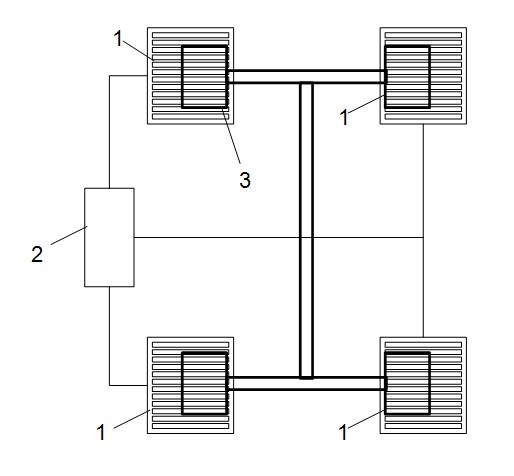

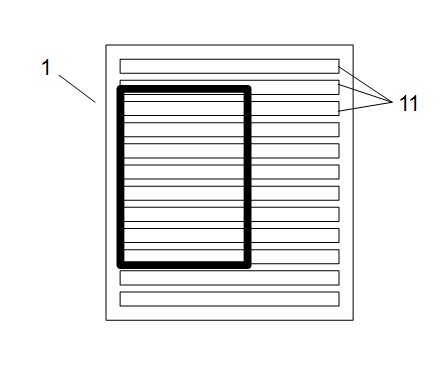

[0030] Such as Figures 1 to 3 As shown, a kind of automobile four-wheel lateral force detector of the present invention comprises at least four measurement platforms 1 and lateral force detection devices 2, and the measurement platforms 1 are respectively connected to the lateral force detection devices 2; each Several measuring rollers 11 are arranged on the measuring platform 1, the measuring rollers 11 are parallel to the axle of the automobile, the measuring rollers 11 are respectively connected to pressure sensors and angular velocity sensors, and the pressure sensors and angular velocity sensors are respectively connected to the lateral force detection The device 2 sends the pressure and angular velocity data of the wheel to the lateral force detection device 2 . The measuring roller 11 is in contact with the wheel surface. The measuring roller 11 fits the partial surface of the wheel along the curvature of the wheel. The measuring platforms 1 are distributed accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com