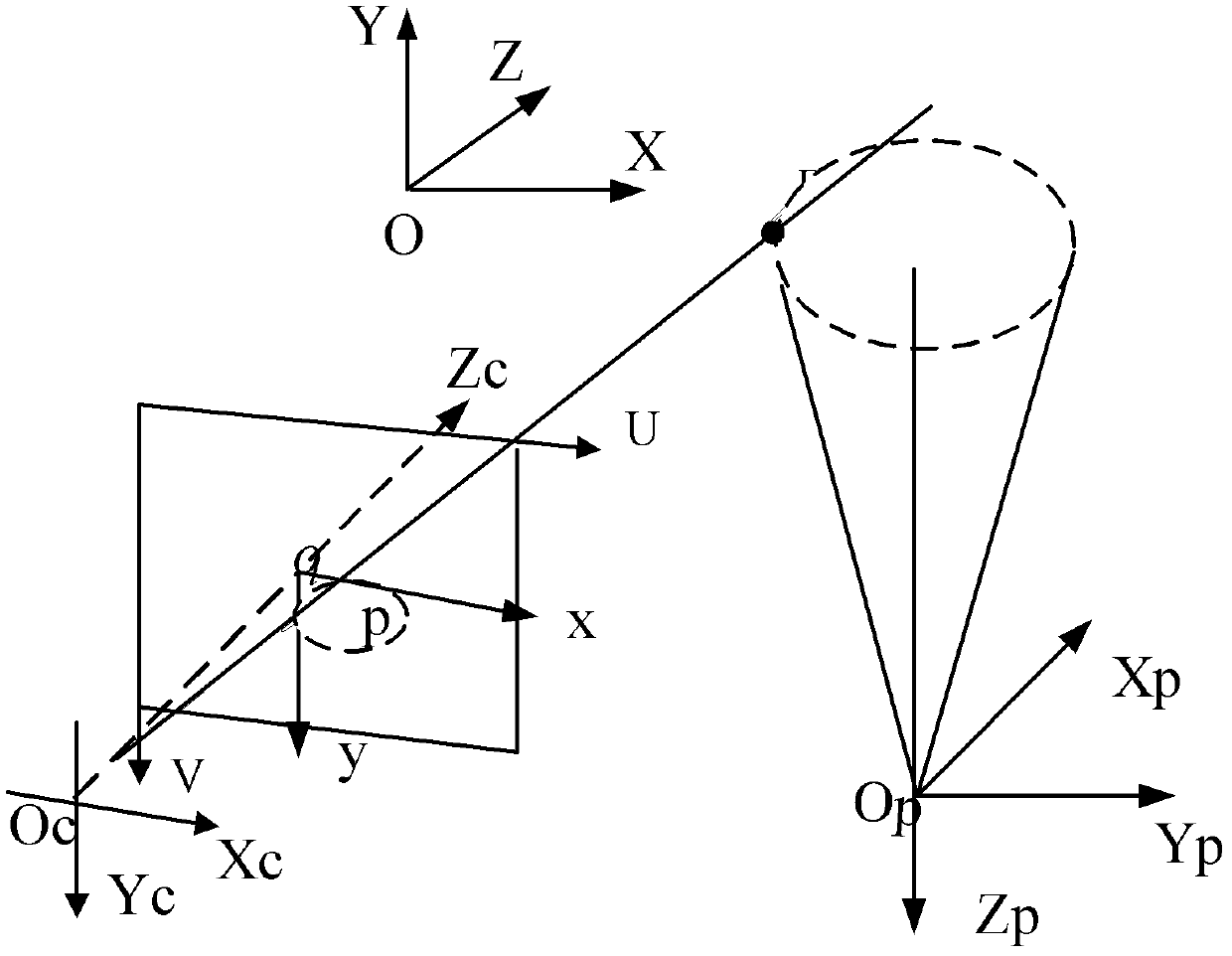

Pipeline inner surface detection system based on circular structured light vision sensor

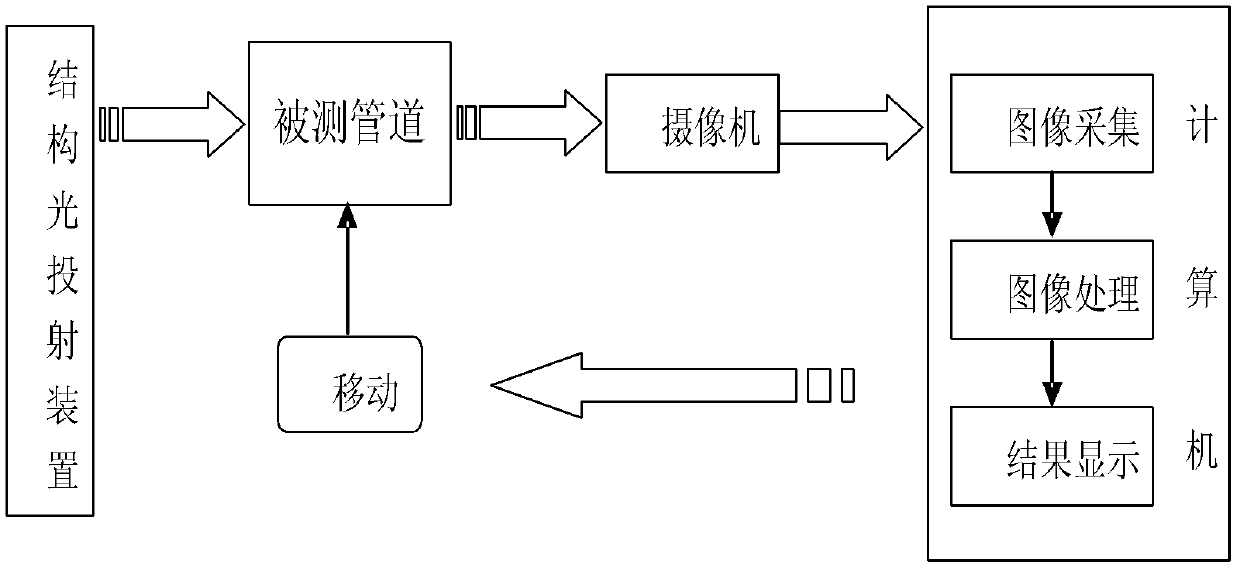

A vision sensor, circular structured light technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of complex structure, inability to achieve accurate 3D measurement, information overlap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

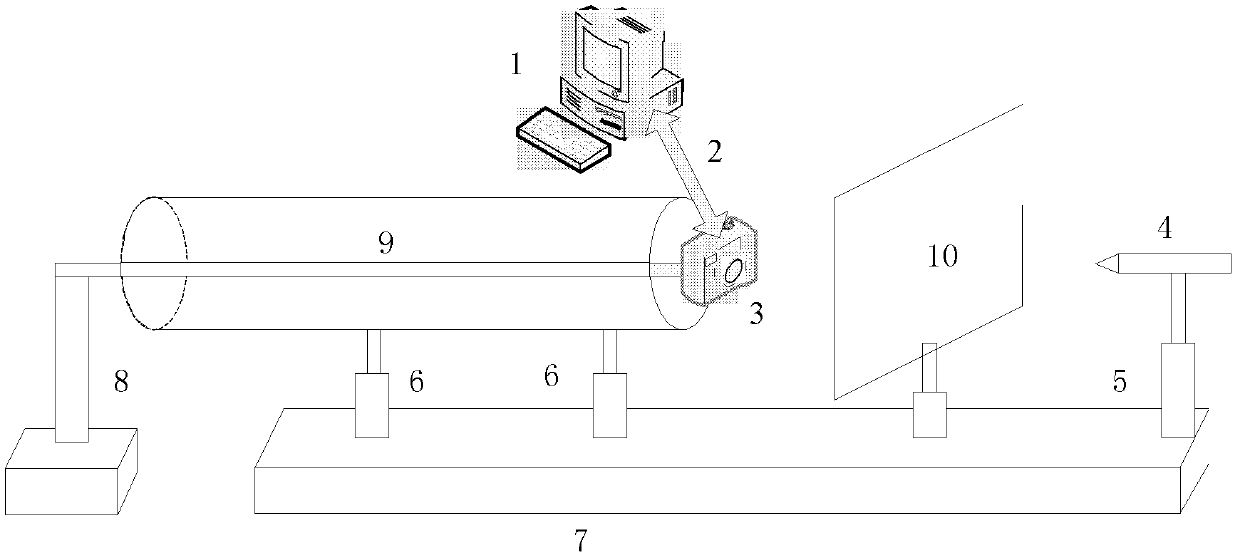

[0054] The experimental process of using the measurement system to measure the inner surface of the pipeline is as follows:

[0055] (1) Put the sliding seat on the one-dimensional guide rail, and connect the pipe support through the rod, then place the pipe on the support along the direction of the one-dimensional guide rail, fix the CCD camera on the support, and pass through the inner surface of the pipe , determine the axial distance between the CCD camera and the circular structured light projector according to the inner diameter of the pipe, and ensure that the optical center of the camera is aligned axially with the center of the conical surface, such as image 3 Show;

[0056] (2) Put the target between the camera and the circular structured light projector, turn on the circular structured light projector, then the circular structured light surface is projected onto the target plane, and a circular light bar is obtained, move the plane target along the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com