Quantitative determination method for component distillation drops of coking crude benzol

A technology for the quantitative determination of coking crude benzene, which is applied in the field of distillation range determination, can solve the problems of slow speed, many human influence factors, and low accuracy of manual observation and test, and achieve the effect of improving economic benefits and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

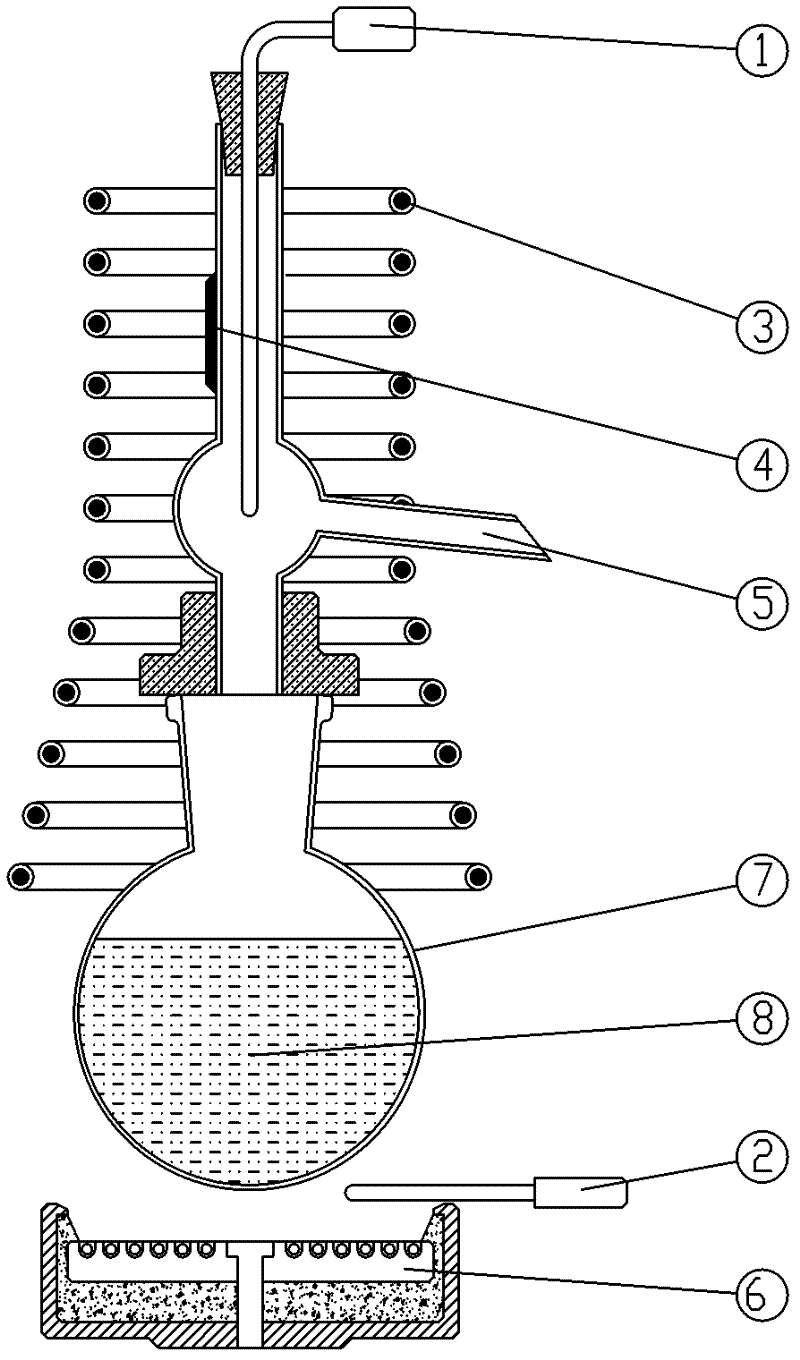

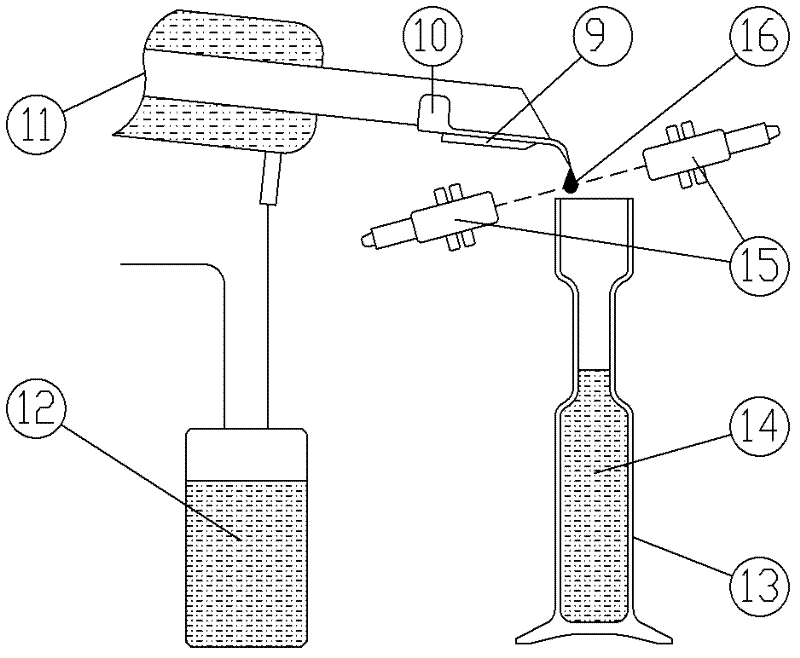

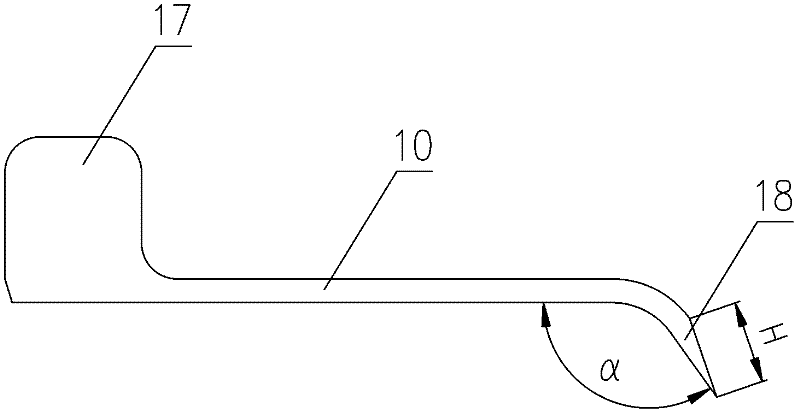

[0024] See figure 1 , is the structural schematic diagram of the embodiment of the distillation temperature tracker on the automatic distillation tester in the implementation process of the present invention. Composition, after the timing of the distillation process starts, the computer starts to heat the crude benzene sample 8 to the electric furnace 10 according to the set heating system according to the displayed value of the temperature control coupler 9. Carry out program control), the temperature of the distillation bottle 7 is also continuously raised, until the component with a lower boiling point reaches the boiling state, and the carbon fiber infrared heater 3 is under the control of the computer, closely tracking the temperature measured by the thermometer 1 to ensure that the thermal resistance 4. The temperature rises synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com