Exhaust gas treatment system, and exhaust gas treatment method

A technology for waste gas treatment and waste gas, which is applied in gas treatment, gaseous discharge wastewater treatment, sludge treatment, etc. It can solve the problems of limitation, inhibition of waste gas treatment amount, inability to deal with desulfurization drainage, etc., to prevent the increase of the concentration of harmful substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

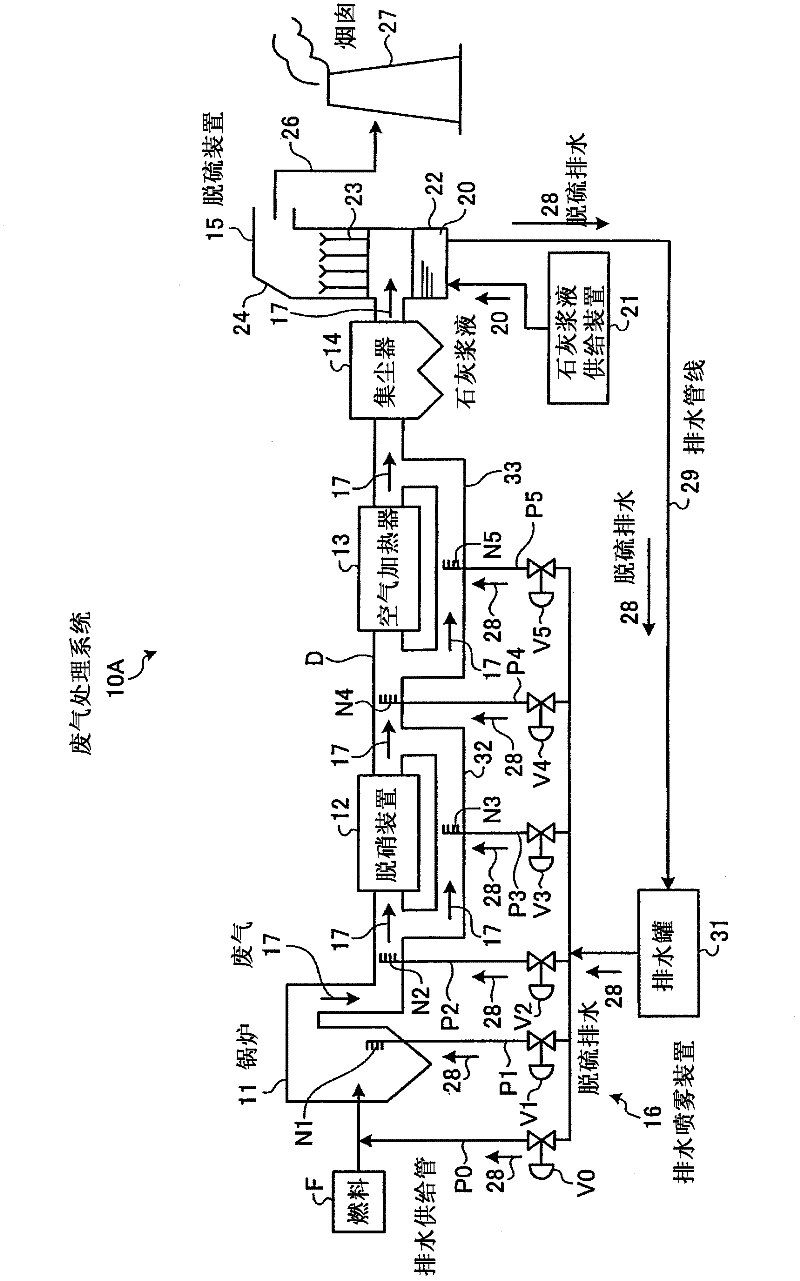

[0040] figure 1 It is a schematic structural diagram of the waste gas treatment system of Example 1. figure 1 The illustrated exhaust gas treatment system 10A converts nitrogen oxides (NO x ), sulfur oxides (SO x ), mercury (Hg) and other harmful substances removal device.

[0041] The exhaust gas treatment system 10A is configured to include: a denitrification device 12 for removing nitrogen oxides in the exhaust gas 17 from the boiler 11; an air heater 13 for recovering the heat of the exhaust gas 17 passing through the denitrification device 12; The dust collector 14 that removes the smoke and dust in the waste gas 17; the desulfurization device 15 that removes the sulfur oxides in the waste gas 17 after the smoke and dust is removed in a wet manner; and the desulfurization wastewater 28 discharged from the desulfurization device 15 is supplied to The route for supplying the fuel F to the boiler 11 , the furnace interior of the boiler 11 , and the drainage spraying devic...

Embodiment 2

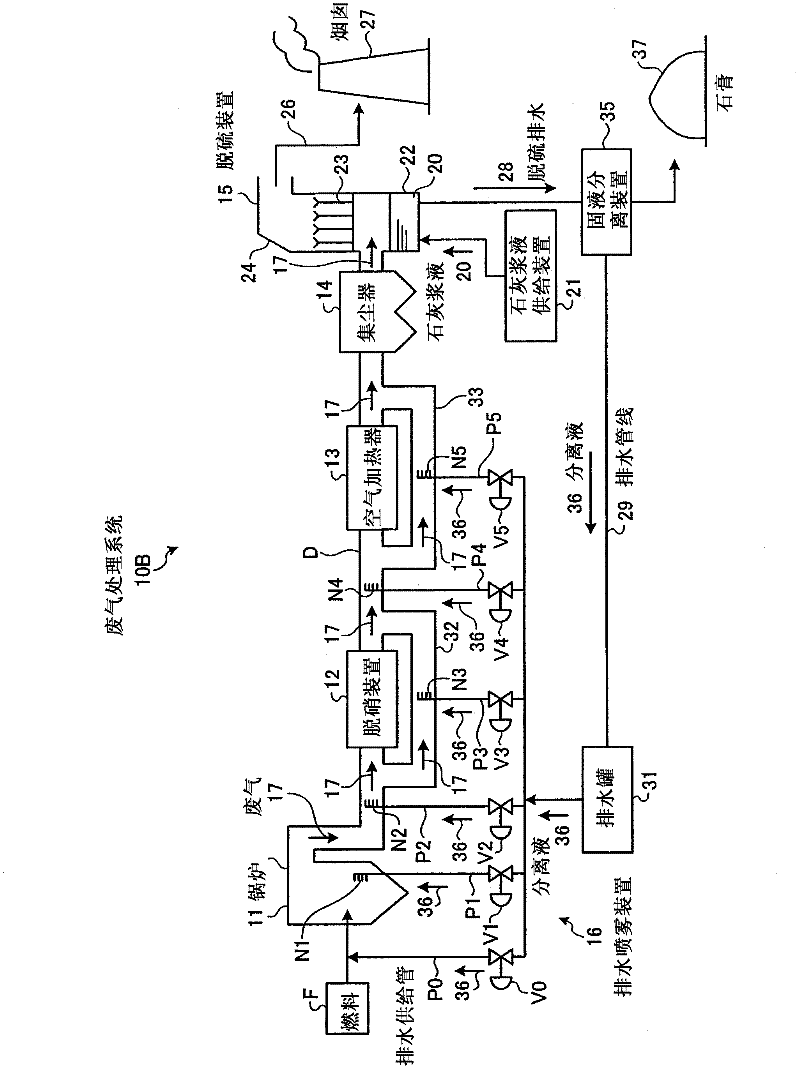

[0074] Next, the exhaust gas treatment system of Example 2 will be described. It should be noted that the same reference numerals are assigned to the same configurations as in the first embodiment described above, and description thereof will be omitted. figure 2 It is a schematic configuration diagram of the exhaust gas treatment system 10B of the second embodiment. In the above-mentioned embodiment 1, the desulfurization wastewater 28 discharged from the desulfurization device 15 is not treated, and the desulfurization wastewater 28 is directly atomized and sprayed into the exhaust gas 17 inside the boiler 11 and the flue D, but in the embodiment 2 In the wastewater treatment system 10B, a solid-liquid separation device 35 is installed in the middle of the drainage line 29, and the desulfurization wastewater 28 from the desulfurization device 15 is separated into solid and liquid by the solid-liquid separator 35, and the separated liquid (treated wastewater) is supplied to ...

Embodiment 3

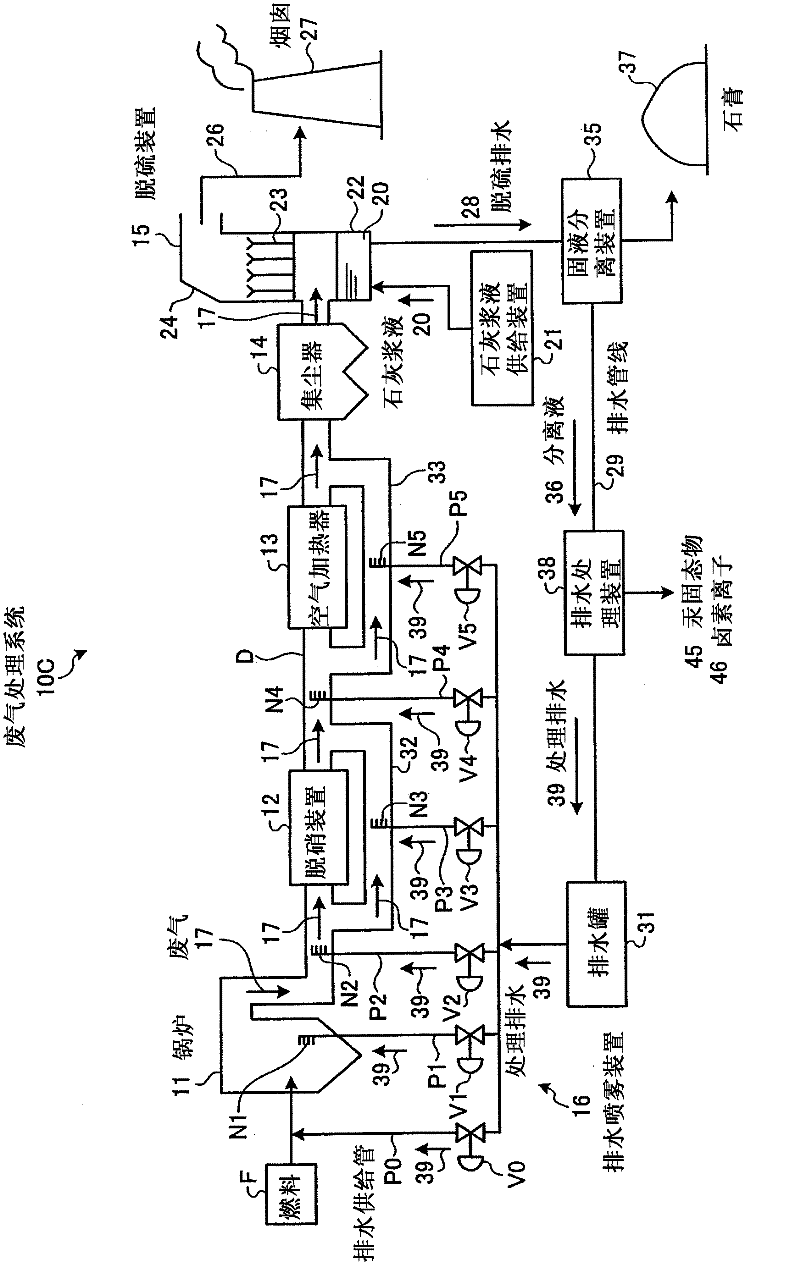

[0078] Next, the exhaust gas treatment system of Example 3 will be described. In addition, the same code|symbol is attached|subjected to the same structure as the said Example 1, 2, and the description is abbreviate|omitted. image 3 It is a schematic structural diagram of 10 C of waste gas treatment systems of Example 3. In the above-mentioned embodiment 2, the solid-liquid separation device 35 is installed in the middle of the drainage line 29, and the desulfurization wastewater 28 from the desulfurization device 15 is separated into solid and liquid by the solid-liquid separation device 35, and the separated liquid 36 is supplied to the The path through which the boiler 11 supplies the fuel F, the inside of the furnace of the boiler 11, the inside of the flue D, and the inside of the bypass pipes 32 and 33. There is a waste water treatment device 38 through which harmful substances and suspended solids in the separation liquid 36 are removed, and then the treated waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com