Positive electrode active material for nonaqueous secondary battery

A positive active material, non-aqueous secondary battery technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve problems such as low cycle characteristics, and achieve excellent performance, low environmental load, and sufficient charge-discharge capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

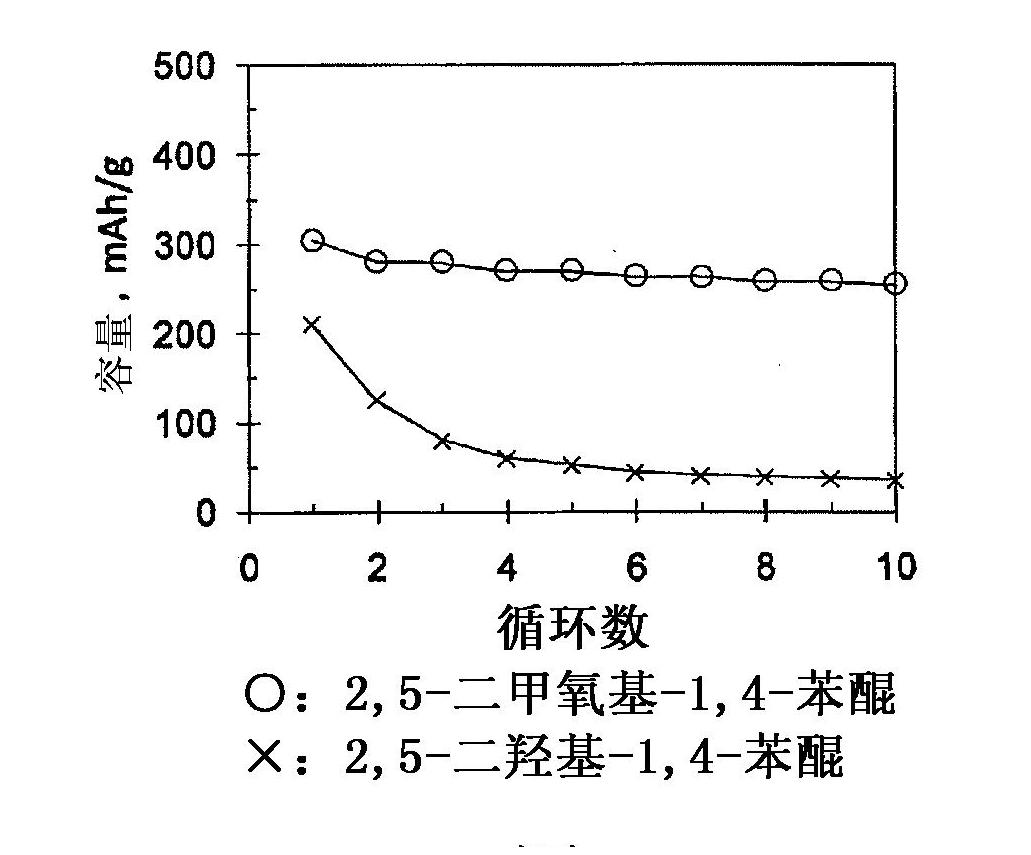

[0040] Use 2,5-dimethoxy-1,4-benzoquinone (Tokyo Chemical Industry Co., Ltd.) as the positive electrode active material, use acetylene black as the conductive additive, and use PTFE as the binder, with a ratio of 4:5:1 A 90 μm thick sheet was prepared by mixing the active material, conductive additive and binder in a weight ratio of . The sheet was bonded to an aluminum mesh (thickness: 110 μm) while being compressed, thereby manufacturing a positive electrode. Using this as a positive electrode material, lithium foil as a negative electrode material, lithium perchlorate / γ-butyrolactone (1.0 mol / L) as an electrolyte, and a glass filter as a separator, a test coin-type battery was fabricated.

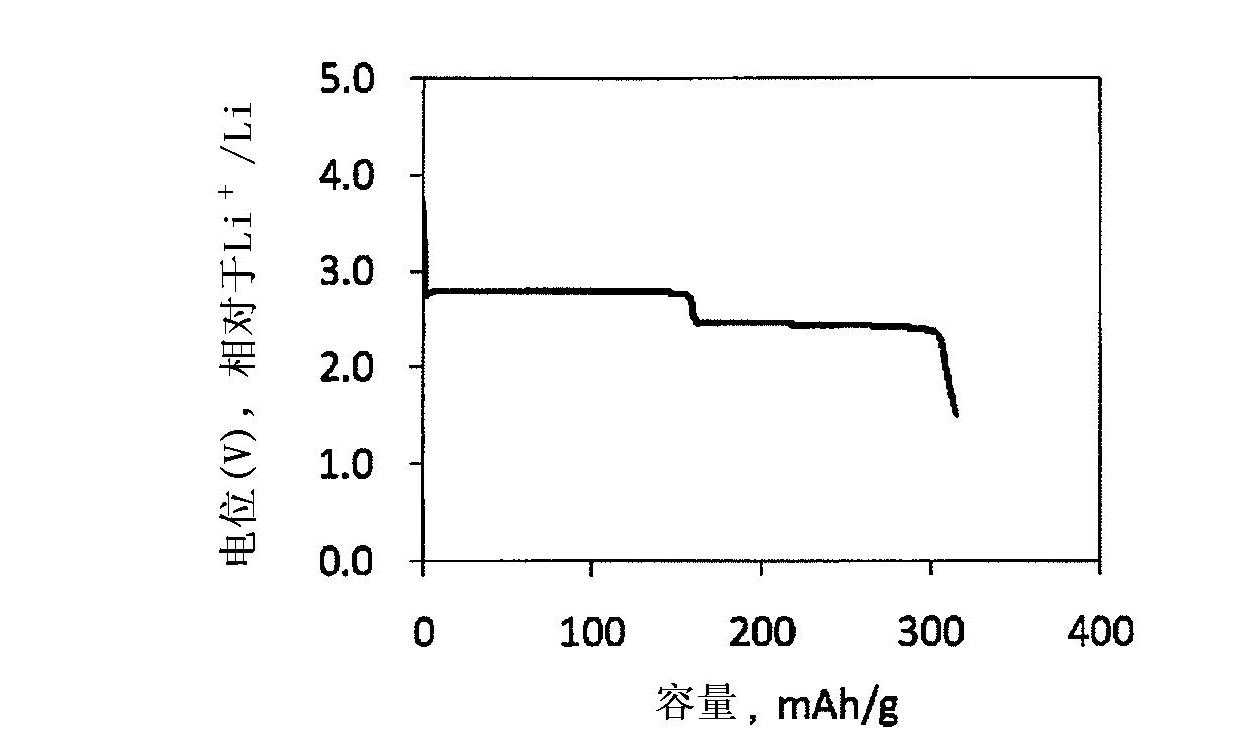

[0041] The battery was subjected to a charge-discharge test in a 30° C. atmosphere at a current density of 10 mA / g or 20 mA / g in a potential range of 1.5 to 3.4 V (vs. Li). figure 1 The initial discharge curve (current density: 10 mA / g) is shown. from figure 1 As is evident in , the d...

Embodiment 2

[0045] 2,5-Difluoro-3,6-dimethoxy-1,4-benzoquinone was synthesized according to the method described in P.P. Sah, S.A. Peoples, Arzneimittelforschung, 1961, 11, pp. 27-33. Using this as a positive electrode active material, using acetylene black as a conductive additive and PTFE as a binder, the active material, the conductive additive, and the binder were mixed in a weight ratio of 4:5:1 to prepare a sheet. The sheet was bonded to an aluminum mesh while being compressed, thereby manufacturing a positive electrode. Using it as the positive electrode material, using lithium foil as the negative electrode material, using lithium bis(pentafluoroethanesulfonyl)imide / γ-butyrolactone (3.0mol / L) as the electrolyte solution, and using glass filter membrane as the separator, manufacturing A coin-type battery was used for the test.

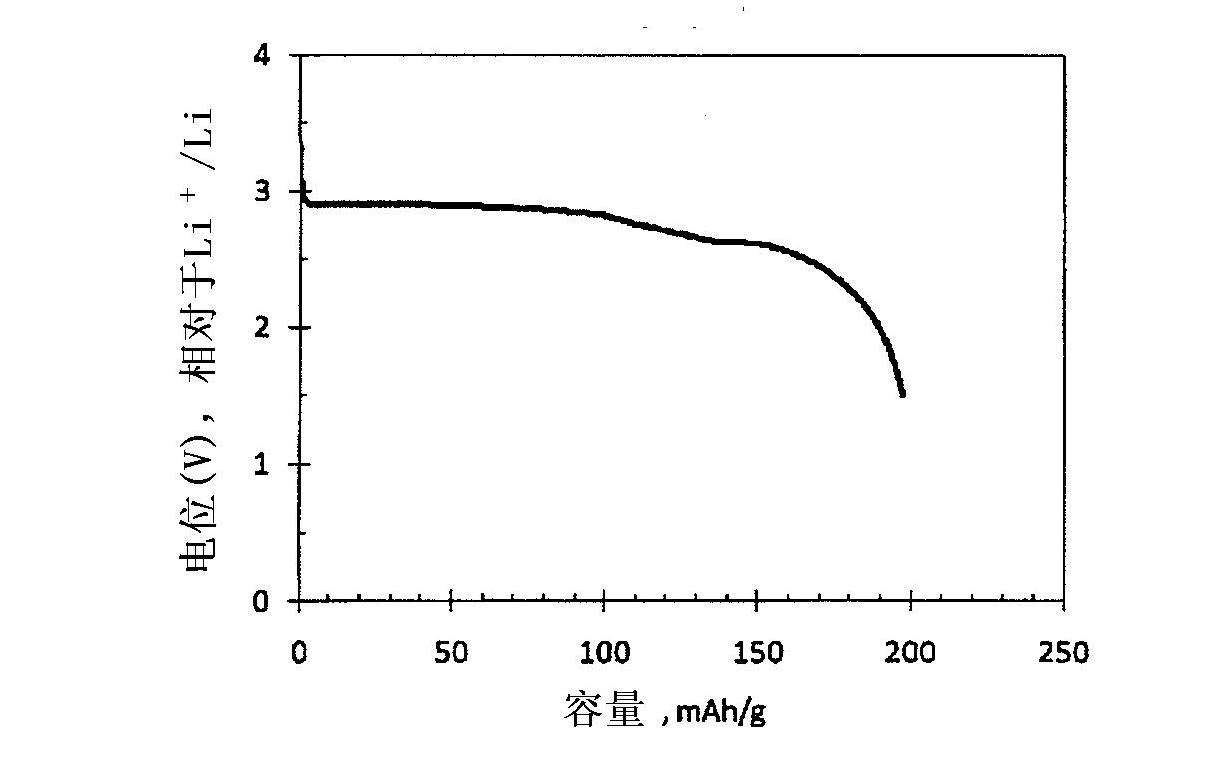

[0046] The battery was subjected to a charge-discharge test at a current density of 20 mA / g in a potential range of 1.5 to 3.8 V (vs. Li). image 3 The i...

Embodiment 3

[0048] According to Keegstra, E.M.D.; van der Mieden, V.; Zwikker, J.W.; Jenneskens, L.W.; Schouten, A.; Kooijman, H.; Veldman, N.; 2,5-dipropoxy-1,4-benzoquinone was synthesized by the method described on page 1105. Using this as a positive electrode active material and ion-conductive glass as a separator, a double-chamber test sealed battery was manufactured. Figure 4 A battery is shown schematically.

[0049] exist Figure 4 In the experimental battery shown in , the current collector for the positive electrode was an aluminum plate, the current collector for the negative electrode was a stainless steel plate, and the negative electrode material was lithium foil. The electrolytic solution on the negative electrode side is lithium perchlorate / γ-butyrolactone (1.0 mol / L). The electrolyte was kept in a glass filter and placed between the negative electrode (lithium foil) and ion-conducting glass. On the other hand, the electrolytic solution on the positive electrode side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com