Drum microfiltration machine

A technology of microfiltration machine and drum, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of complex structure, large occupied area, increased failure rate, etc., and achieve compact overall structure and small occupied area. The effect of small size and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

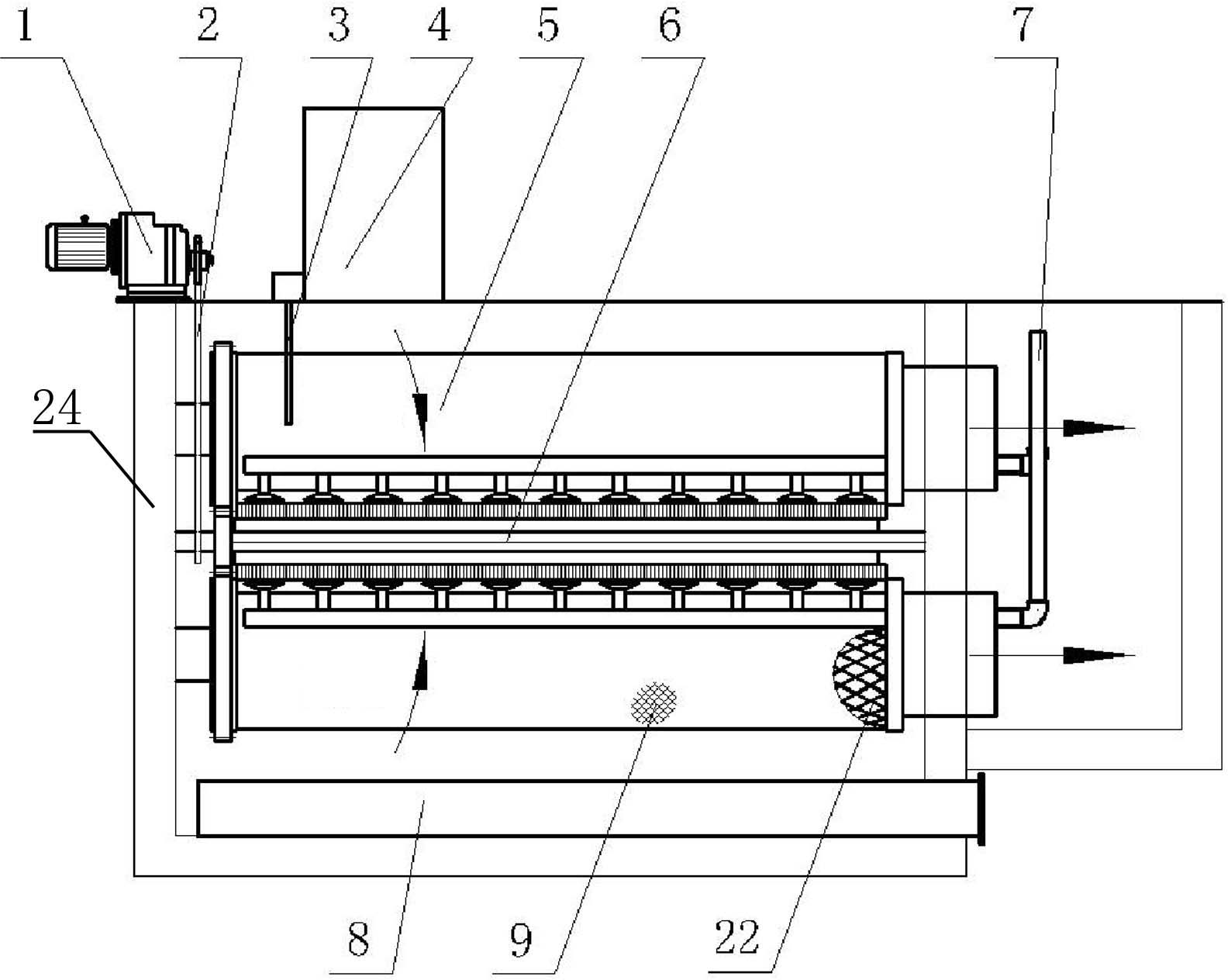

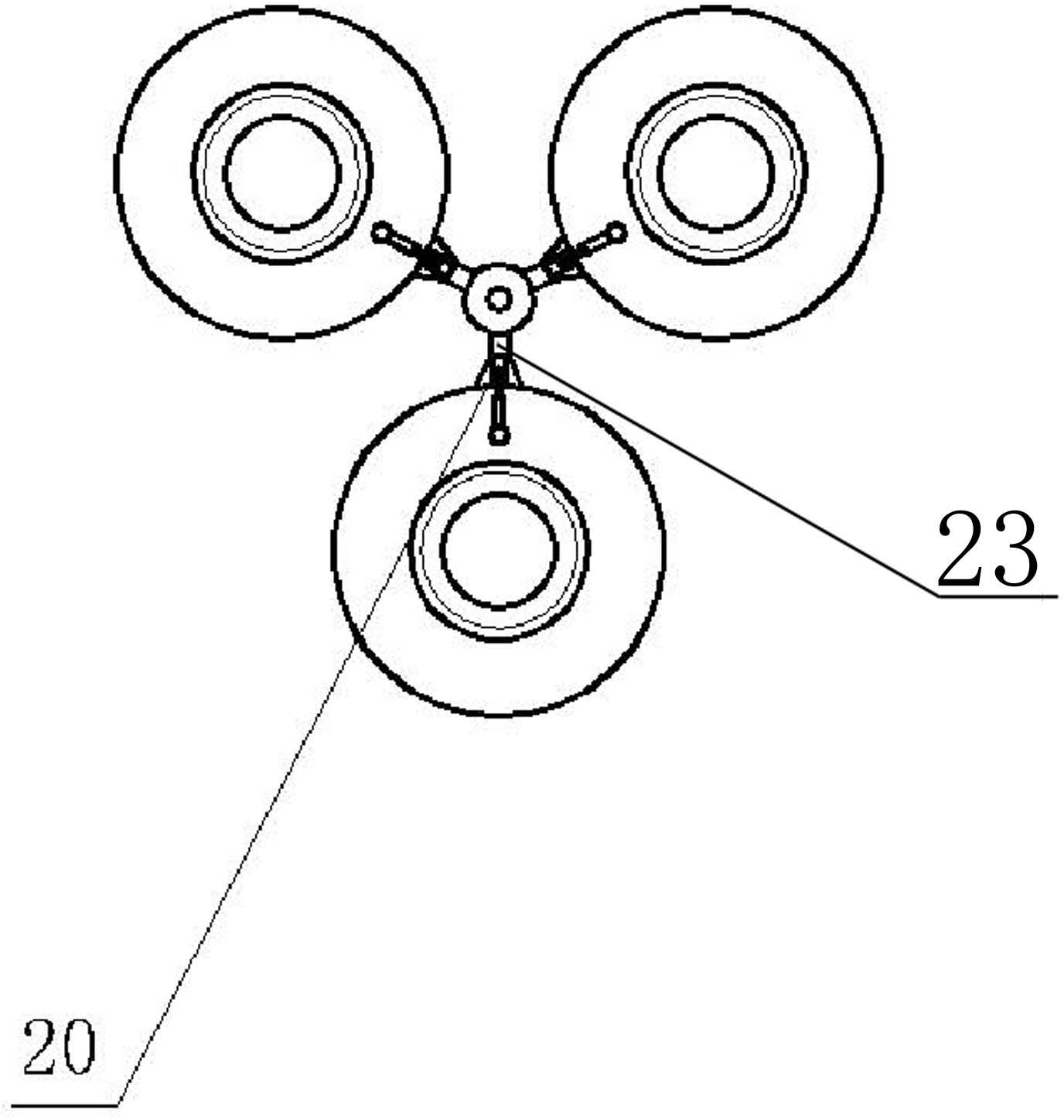

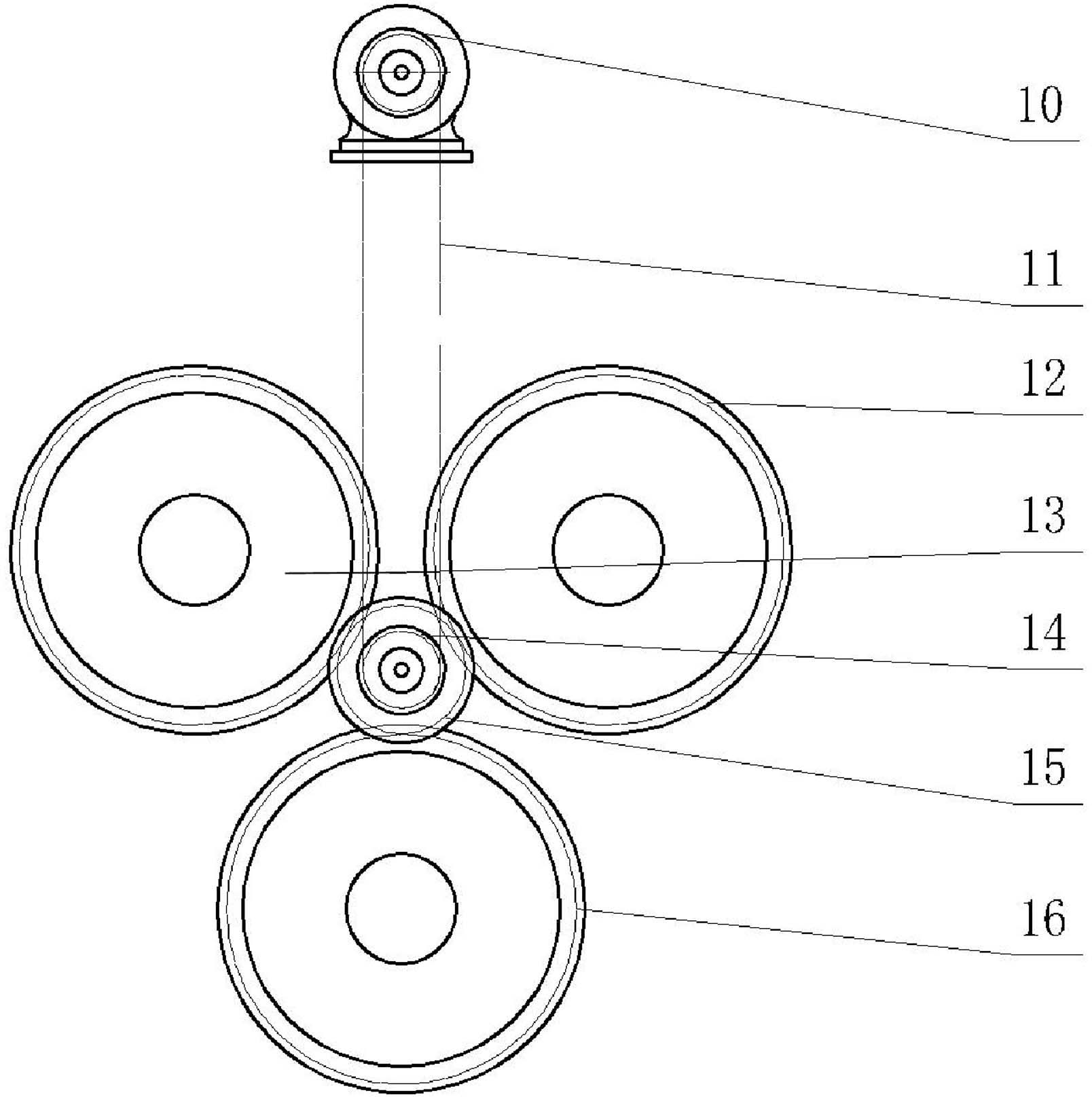

[0014] exist figure 1 and figure 2 , the present invention is a kind of drum microfilter, when the microfilter adopts external water inlet, it mainly comprises that the microfilter cartridge assembly is arranged horizontally, the microfilter cartridge assembly is located in the filter sedimentation tank 24, and the top of the filter sedimentation tank 24 is provided with There is a driving motor 1, and an electric control system 4 is arranged on the top of the filtration sedimentation tank 24, and the input end of the electric control system 4 is connected with a liquid level monitoring device 3, and the liquid level monitoring device 3 extends into the filtration sedimentation tank 24, and the electric control system The output end of 4 is connected with drive motor 1, and described micro-filter cartridge assembly mainly comprises functional shaft 6 and filter drum group 5, and the cylinder body of each drum of filter drum group 5 is support net 22, and the support net 22 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com