A kind of high flux polyphenylene ether microfiltration membrane and preparation method thereof

A polyphenylene ether, microfiltration membrane technology, applied in chemical instruments and methods, ultrafiltration, membrane technology and other directions, can solve the problems of high porosity, complex preparation process, and good permeability of microfiltration membranes, and achieve membrane permeability. Good permeability, simple preparation process and equipment, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the titanium dioxide colloidal crystal template is the same as the silica colloidal crystal template, wherein what adopts is the titanium dioxide colloidal dispersion liquid, and the raw material in the described titanium dioxide colloidal dispersion liquid is the volume ratio of ethyl orthotamate, 1:3:3.85:80, Water and hydrochloric acid (36wt%-38wt%) are added to the isopropanol solution or absolute ethanol.

[0039] The size of the colloidal crystal template used in the present invention is: 1cm×1cm×200nm˜3cm×3cm×2.1 μm.

[0040]The high-throughput polyphenylene ether microfiltration membrane of the present invention adopts the combination technology of the breath pattern method and the colloidal crystal template method, wherein the colloidal crystal template method refers to coating the brominated polyphenylene ether solution on the surface of the colloidal crystal template , and then adopt the breath pattern method to form micropores, and ...

Embodiment 1

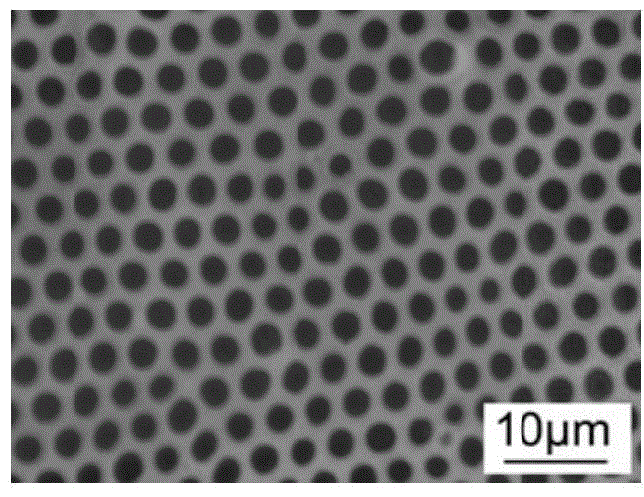

[0042] The high-throughput polyphenylene ether microfiltration membrane of this embodiment includes a polyphenylene ether microfiltration membrane body and filtration pores passing through the polyphenylene ether microfiltration membrane body, and the pore diameter at one end of the filtration micropore is 2.5 μm. The pore diameter at the other end is 200 nm, and the thickness of the polyphenylene ether microfiltration membrane body is 4.1 μm.

[0043] The above-mentioned high-throughput polyphenylene ether microfiltration membrane adopts a preparation method using the combination technology of the breath pattern method and the colloidal crystal template method, including the following steps:

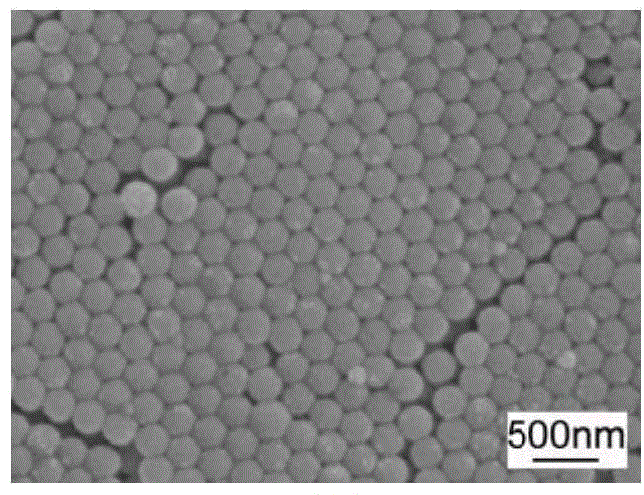

[0044] The colloidal crystal template used in this embodiment is a silica colloidal crystal template with an average particle diameter of 200 nm on the surface.

[0045] Add 100 mg of brominated polyphenylene ether powder into 1 g of carbon disulfide solvent, and fully dissolve to form ...

Embodiment 2

[0052] The high-throughput polyphenylene ether microfiltration membrane of this embodiment includes a polyphenylene ether microfiltration membrane body and filtration pores that run through the polyphenylene ether microfiltration membrane body. The diameter of one end of the filtration micropores is 2 μm, and the other The pore diameter at one end is 300 nm, and the thickness of the polyphenylene ether microfiltration membrane body is 4.2 μm.

[0053] The above-mentioned high-throughput polyphenylene ether microfiltration membrane adopts a preparation method using the combination technology of the breath pattern method and the colloidal crystal template method, including the following steps:

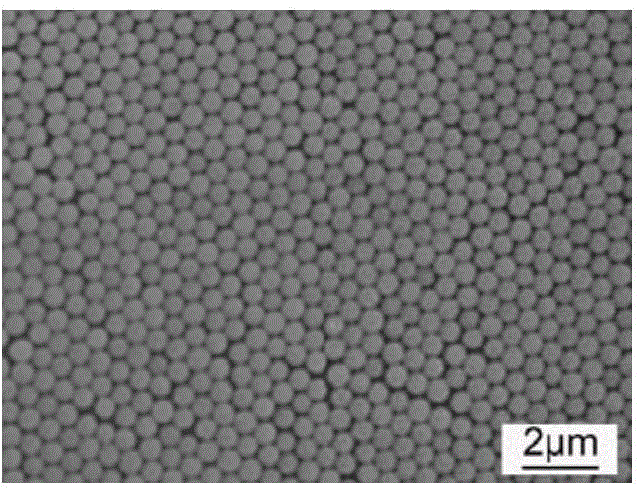

[0054] The colloidal crystal template used in this embodiment is a silica colloidal crystal template with an average particle diameter of 300 nm on the surface.

[0055] Add 150 mg of brominated polyphenylene ether into 1 g of carbon disulfide solvent and fully dissolve to form a bromina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com