Composite constructed wetland desalination system based on cdi

A constructed wetland and composite technology, applied in the field of composite constructed wetland desalination system, can solve the problems affecting the normal operation of the constructed wetland treatment system, the wetland soil layer is easy to be blocked, and the desalination effect is poor, so as to reduce secondary pollution and promote nitrification Good effect, breathability and water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

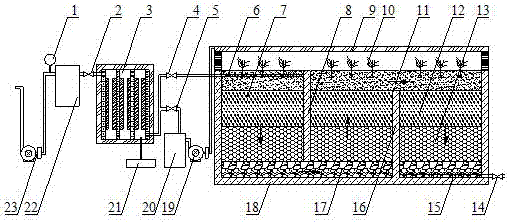

[0032] A compound constructed wetland desalination system based on CDI. The composite constructed wetland desalination system consists of a pretreatment system and a composite vertical flow constructed wetland system. Such as figure 1As shown: the pretreatment system includes a first booster pump 23 , a flow meter 1 , a grille 22 , a CDI device 3 , a conductivity meter 21 , a water tank 20 , a second booster pump 19 and a salt drying plate 9 . The water inlet of the first booster pump 23 communicates with the sewage to be treated through the pipeline, and the water outlet of the first booster pump 23 communicates with the water inlet of the grid 22 through the pipeline, and the water inlet of the grid 22 is provided with a flowmeter 1, The water outlet of the grid 22 communicates with the water inlet of the first shut-off valve 2 through the pipeline, the water outlet of the first shut-off valve 2 communicates with the water inlet of the CDI device 3, and the water outlet of ...

Embodiment 2

[0049] A compound constructed wetland desalination system based on CDI. Except following technical parameter, all the other are with embodiment 1:

[0050] The heights of the gravel layer 17, the biological ceramsite layer 13, the zeolite layer 12 and the soil layer 11 are 15-18 cm, 32-36 cm, 32-36 cm and 15-18 cm in sequence.

[0051] In the constructed wetland, 4 partition walls are evenly arranged along the left and right directions, and the 4 partition walls divide the constructed wetland into 5 vertical flow treatment pools 7, and the distance between each partition wall is 3~6m.

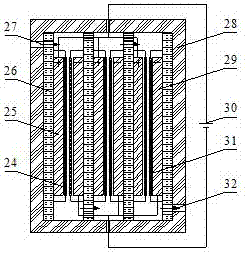

[0052] The bottom plate and the top plate of the housing 28 are symmetrically opened with 2~4 installation slots, and the 2~4 installation slots are evenly arranged, and each installation slot is equipped with an insulating partition 26; the DC voltage of the power supply 30 is 1.5~1.6V.

[0053] The thickness of the insulating partition 26 is 4-6mm; the material of the insulating partition 26...

Embodiment 3

[0061] A compound constructed wetland desalination system based on CDI. Except following technical parameter, all the other are with embodiment 1:

[0062] The heights of the gravel layer 17, the biological ceramsite layer 13, the zeolite layer 12 and the soil layer 11 are 17-20cm, 35-40cm, 35-40cm and 17-20cm in sequence.

[0063] In the constructed wetland, 6 partition walls are evenly arranged along the left and right directions, and the 6 partition walls divide the constructed wetland into 7 vertical flow treatment pools 7, and the distance between each partition wall is 5-8m.

[0064] The bottom plate and the top plate of the housing 28 are symmetrically opened with 4~8 installation slots, and the 4~8 installation slots are evenly arranged, and each installation slot is equipped with an insulating partition 26; the DC voltage of the power supply 30 is 1.6~1.9V.

[0065] The thickness of the insulating partition 26 is 6-10mm; the material of the insulating partition 26 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com