Machining device

A technology for processing equipment and processing fluids, which can be applied to combined equipment, electrical components, and dispersed particle separation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

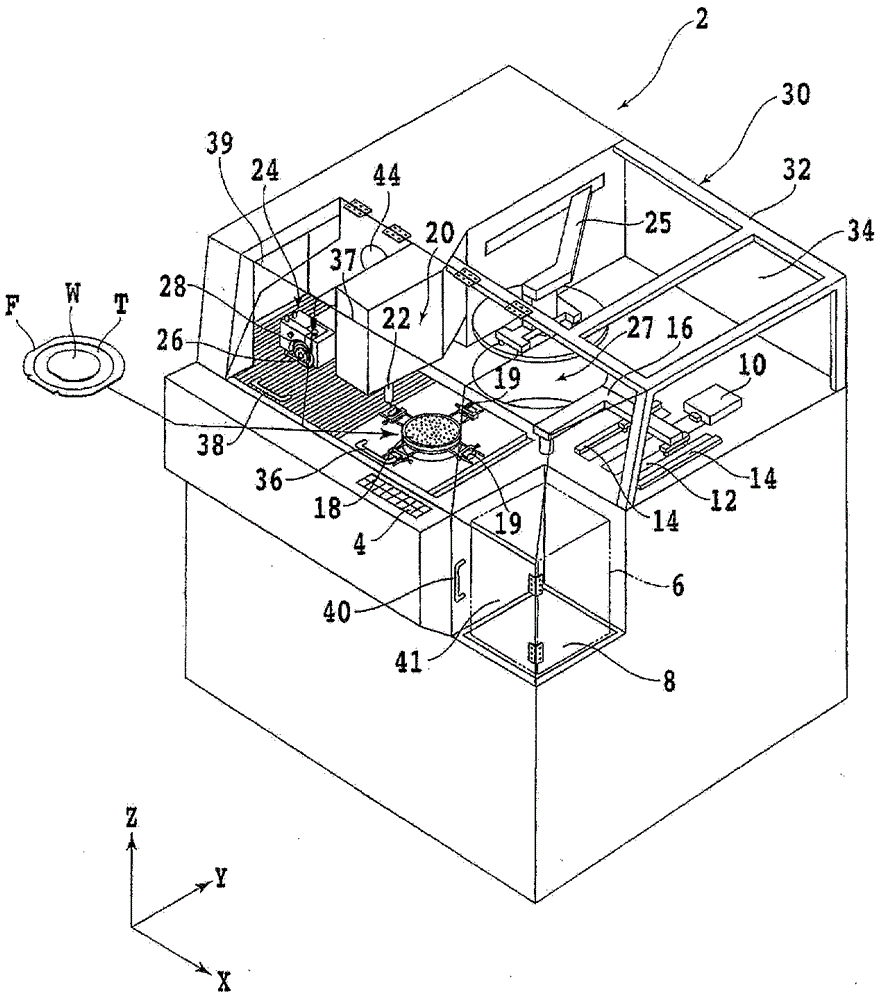

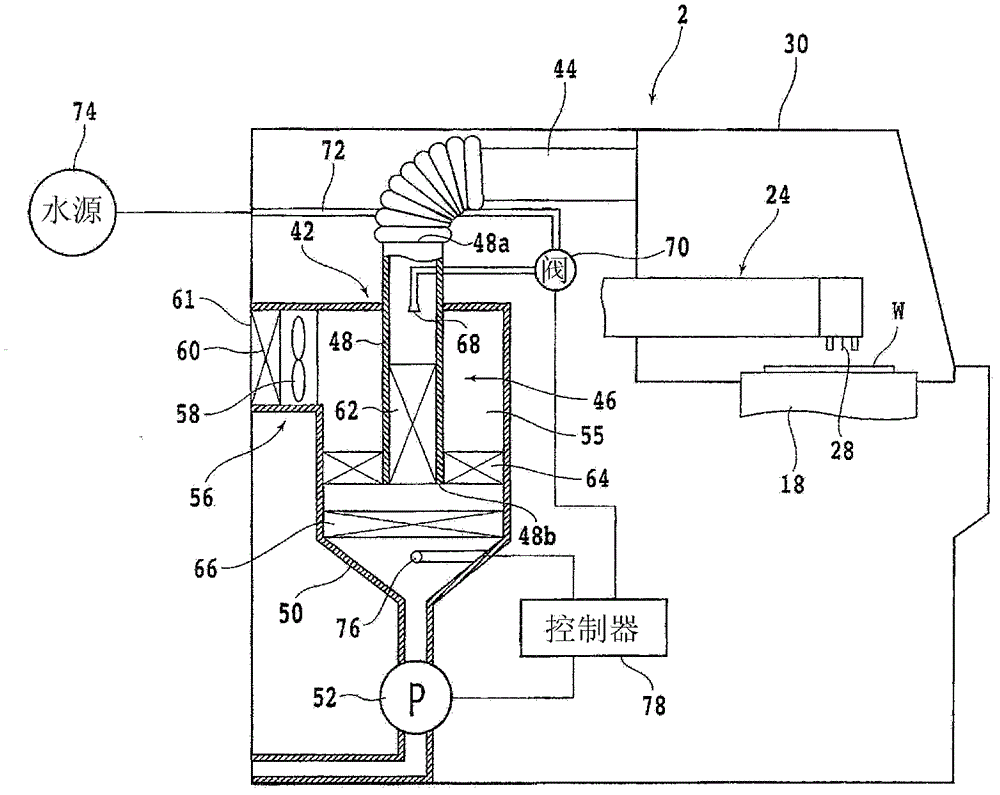

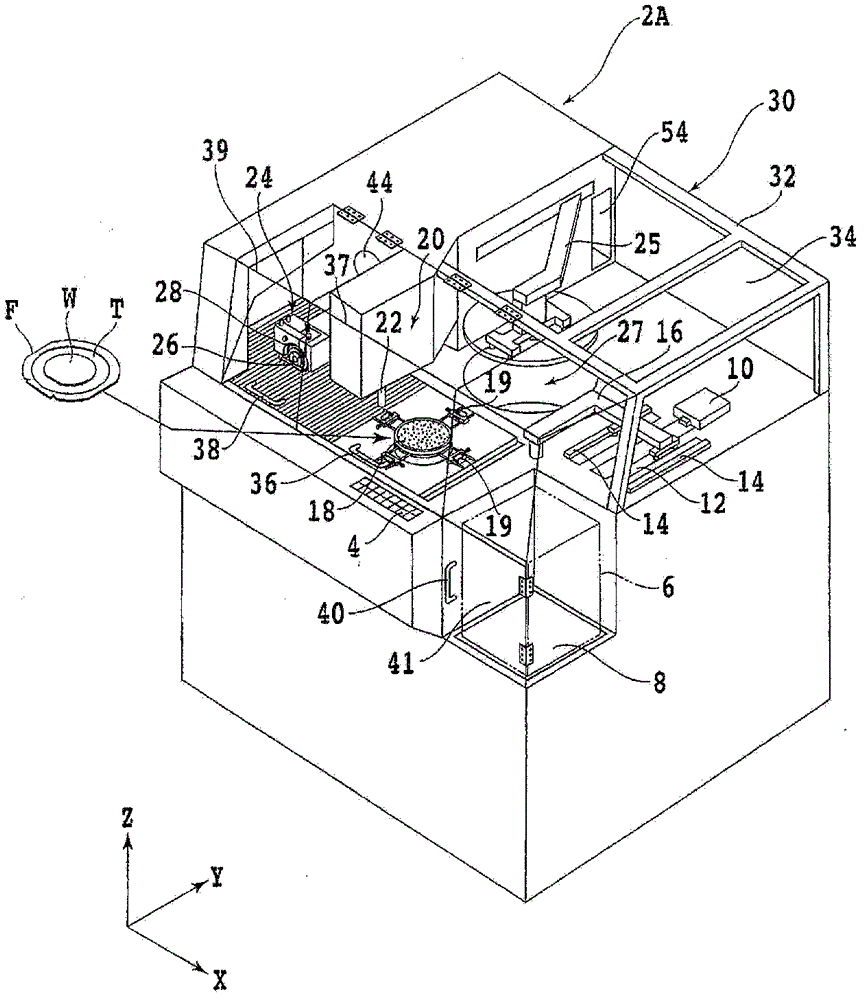

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. refer to figure 1 , shows an external perspective view of a cutting device (scribing device) 2 according to the first embodiment of the present invention, which is one type of processing device. On the front side of the cutting device 2, an operation panel 4 for an operator to input instructions to the device such as machining conditions is provided.

[0035] The wafer W to be cut is attached to a dicing tape T as an adhesive tape, and the outer peripheral portion of the dicing tape T is attached to an annular frame F. As shown in FIG. As a result, the wafer W is supported by the ring frame F via the dicing tape T, and a plurality of (for example, 25) wafers are accommodated in the wafer cassette 6 . The wafer cassette 6 is placed on a cassette elevator 8 capable of moving up and down.

[0036] Arranged behind the wafer cassette 6 is an unloading and loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com