Method for optimizing plunge milling machining of slotting of integral impeller

A technology of integral impeller and optimization method, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., to achieve the effect of avoiding interference, small blade deformation, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

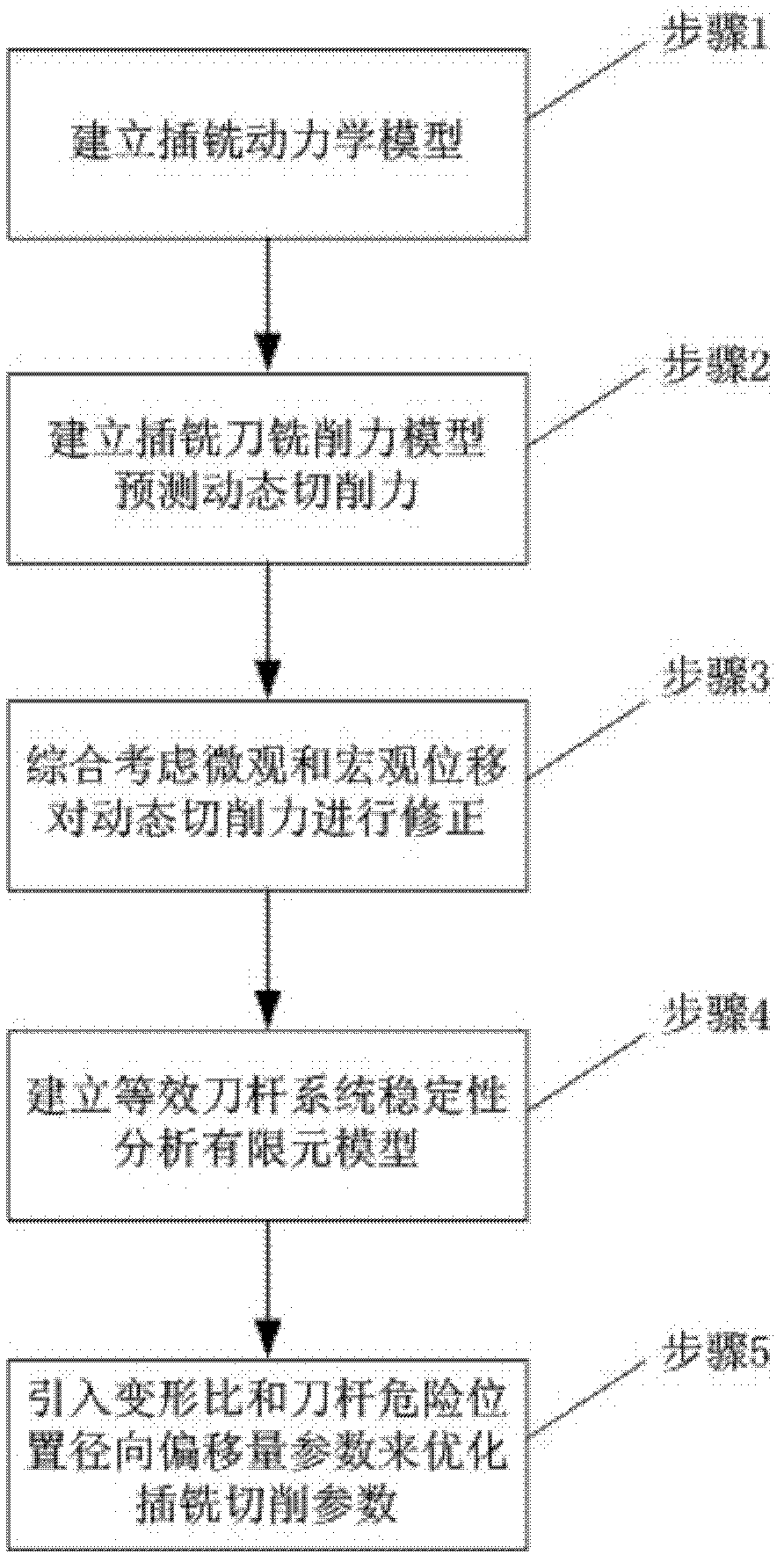

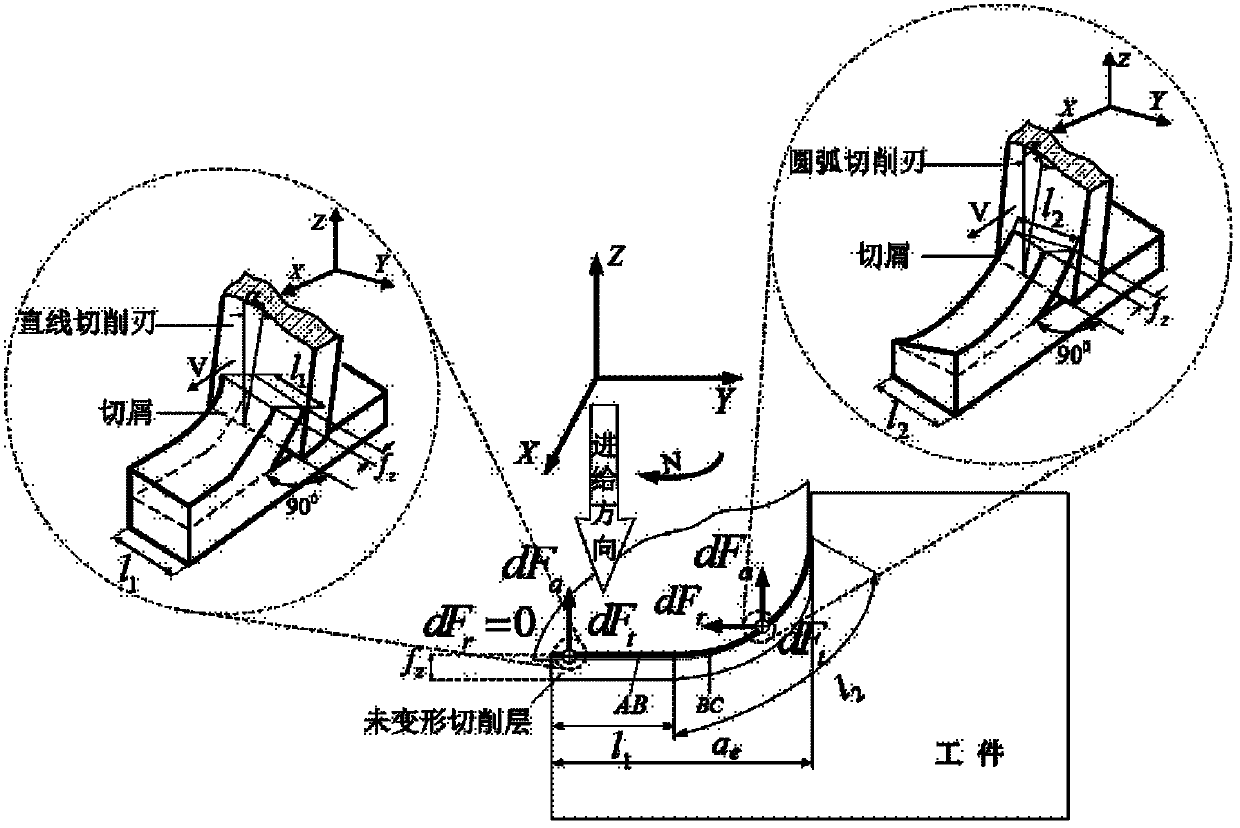

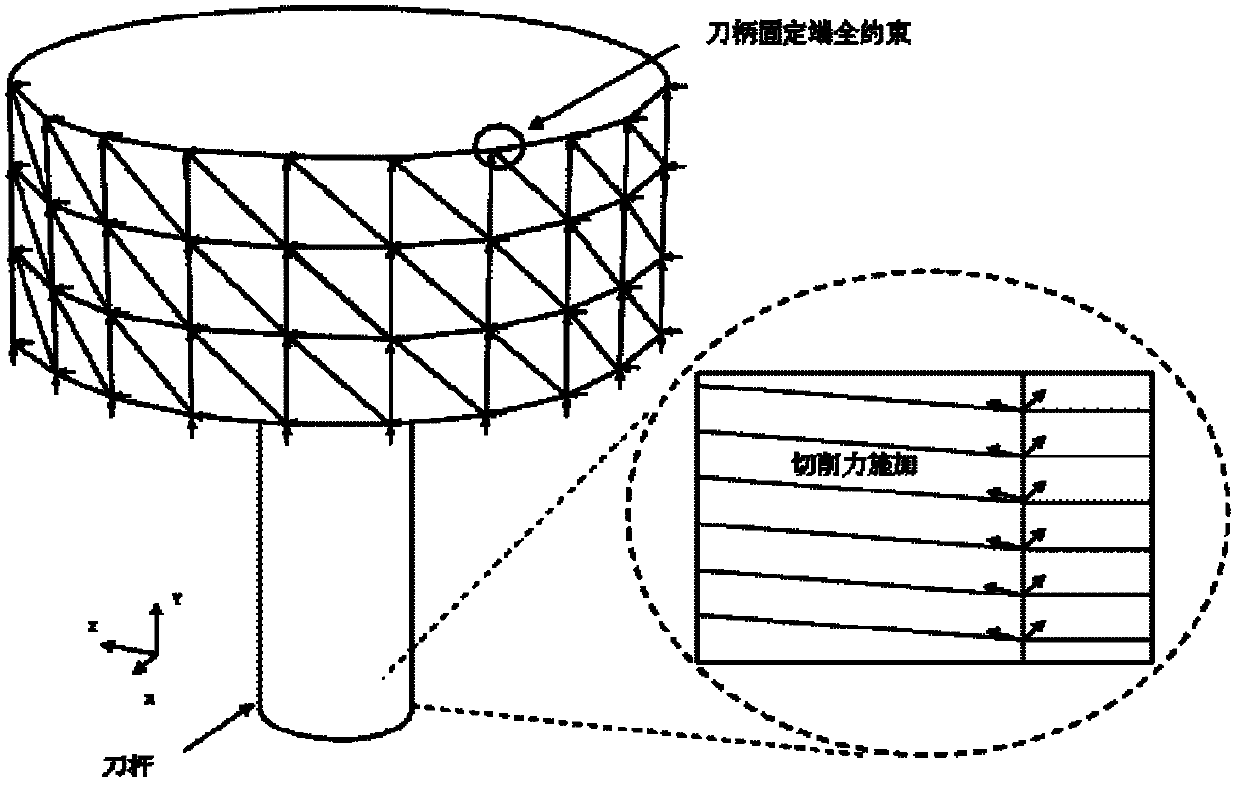

[0018] The content of the overall impeller slotting milling process optimization method according to the present invention is to set up the milling dynamics model and the milling force model of the asymmetric plunge milling of the large fillet milling cutter, and the modal parameters obtained by the modal test and The dynamic milling force obtained from the milling force model is substituted into the dynamic equation to further correct the cutting force; the equivalent tool holder system stability analysis finite element model is established, and the deformation ratio and the radial offset of the dangerous position of the tool holder are introduced. In order to obtain optimized cutting parameters.

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the details of each step will be set forth.

[0020] The embodiment adopts DMU70V CNC milling center, the tool adopts φ12 SECO integral replaceable head t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com